Film cooling device

A technology of film cooling and cooling pipes, applied in heat exchange equipment, fixed conduit components, heat exchanger types, etc., can solve problems affecting later use, easy adhesion, etc., and achieve the effect of simple structure and prevention of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

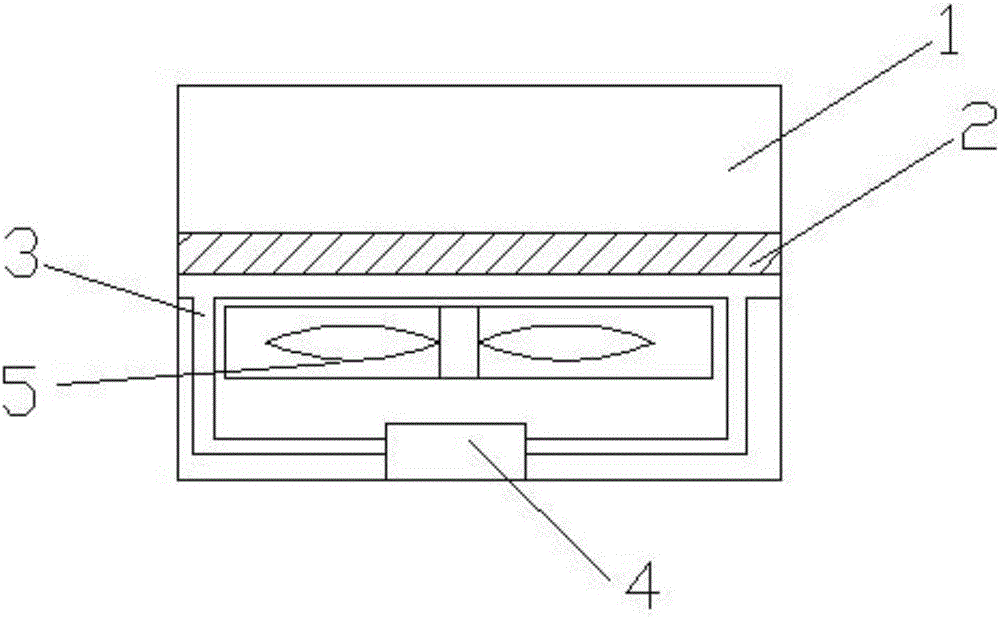

[0012] Such as figure 1 As shown in -2, a film cooling device includes a body frame 1, a cooling plate 2, a cooling pipe 3, a pump 4, and a fan 5. It is characterized in that: the body frame 1 is horizontally provided with a cooling plate 2, and the cooling plate 2 The lower end of the pump is provided with a cooling pipe 3, the cooling pipe 3 is connected to the pump 4, and the fan 5 is arranged at the lower end of the cooling pipe 3.

[0013] Preferably, the cooling plate 2 is made of metal material, so that the effect of cooling and heat dissipation is good.

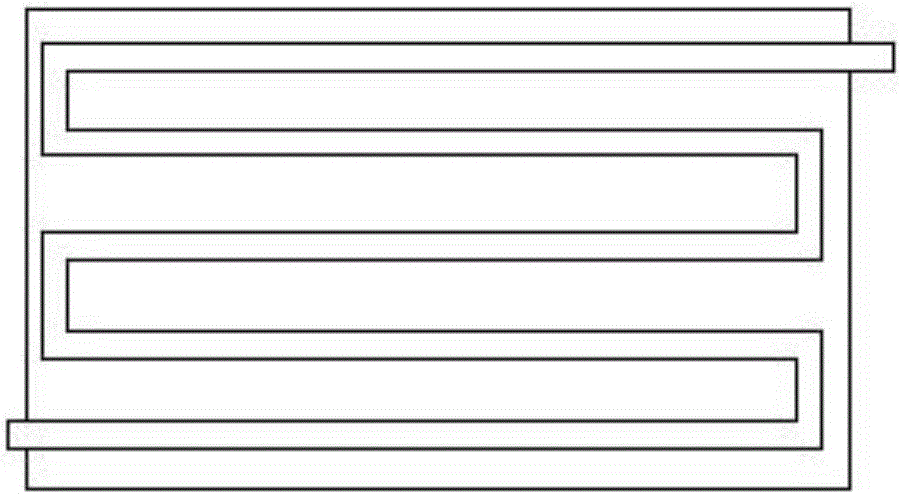

[0014] Preferably, the cooling pipe 3 has a spiral structure, so as to increase the heat dissipation area.

[0015] Preferably, the cooling pipe 3 is connected with the pump 4 to form a closed pipeline, which facilitates the liquid circulation in the cooling pipe 3 .

[0016] Preferably, the cooling pipe 3 is a hollow metal pipe, which is beneficial to the liquid circulation in the cooling pipe 3, so that the effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com