Deep hole groove measurement device and usage method

A measuring device and groove technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of limited jaw length, limited measurement depth, and inability to measure deep holes, and achieve the effect of solving difficult measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

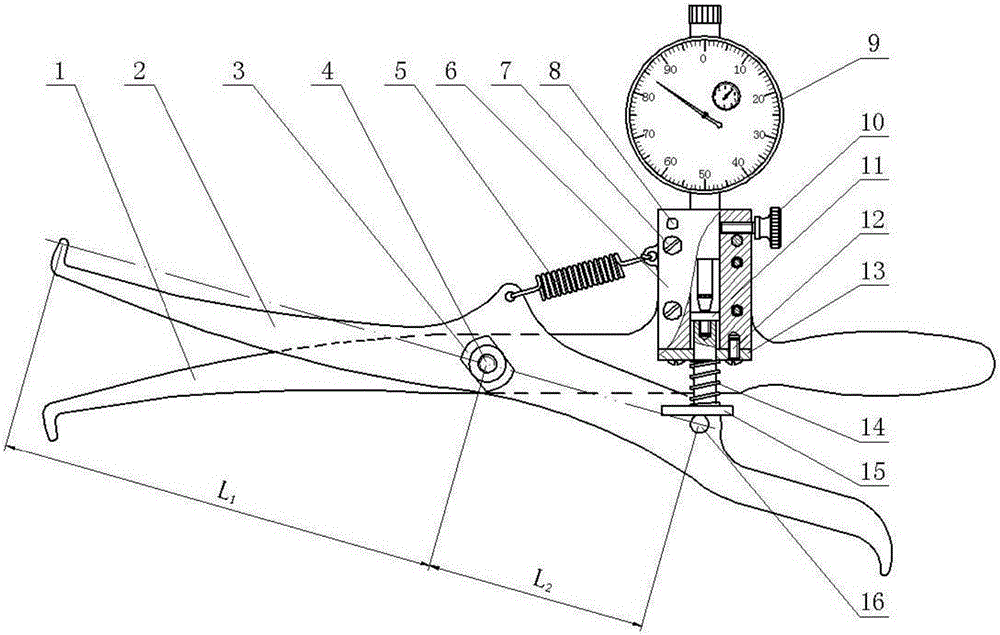

[0017] Embodiment 1, referring to accompanying drawing, a kind of deep hole groove measuring device, it comprises: lower jaw 1, upper jaw 2, flat nut 3, flat head screw 4, extension spring 5, support block 6, sink Head screw 7, cylindrical pin 8, dial indicator 9, knurled screw 10, top cap 11, round head screw 12, baffle plate 13, compression spring 14, ejector rod 15, pin shaft 16;

[0018] After the upper jaw 2 and the lower jaw 1 intersect, they are connected together with the flat nut 3 through the flat head screw 4 in the middle, forming a scissors structure with one end as the handle end and the other end as the working end. The upper jaw 2 and the lower jaw The claw 1 can rotate around the flat head screw 4;

[0019] The working end of the upper jaw 2 is bent outward to form a tip, and the handle end is provided with a pin shaft 16; the distance between the tip axis and the connection point of the upper jaw 2 and the lower jaw 1 is L1, and the connection point and the p...

Embodiment 2

[0024] Embodiment 2, a kind of deep hole groove measuring device using method, it uses the deep hole groove measuring device as described in embodiment 1, and comprises the following steps:

[0025] A. Use the outer diameter micrometer to calibrate the deep hole groove measuring device, and rotate the dial of the dial indicator 9 so that the pointer is aligned with the "0" position;

[0026] B. Hold the handle end of the upper jaw 2 and the lower jaw 1 tightly, close the working ends of the upper jaw 2 and the lower jaw 1, and then extend the working end into the inner hole of the part to be tested, so that the upper jaw 2, The tip of the lower jaw 1 is respectively aligned with the two ends of the inner hole groove of the part to be tested;

[0027] C. Read the value of the dial indicator 9, multiply the value by 2, which is the size value of the inner hole groove of the part to be tested;

[0028] D. After the measurement is completed, hold the handle ends of the upper jaw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com