Data correction method for improving measurement precision

A technology for data correction and measurement accuracy, which is applied in the direction of measurement devices, speed/acceleration/shock measurement equipment testing/calibration, speed/acceleration/shock measurement, etc. Poor performance and other problems, to achieve the effect of high precision, strong versatility, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

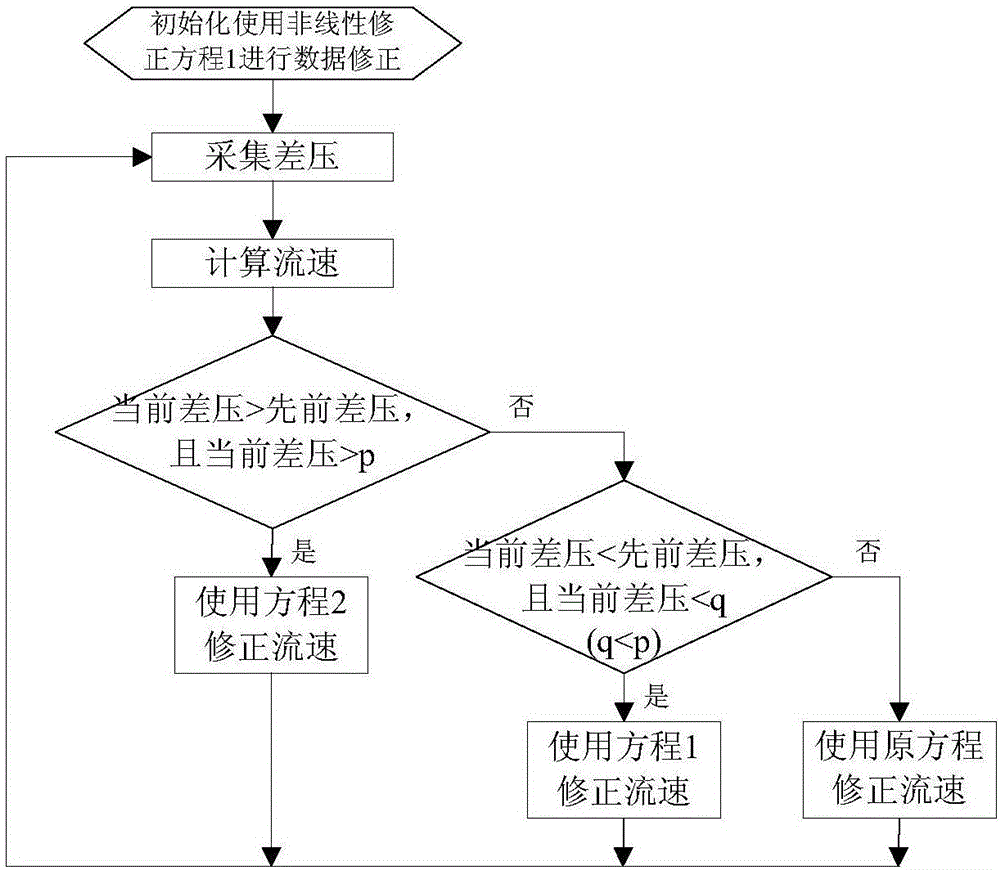

[0017] The present invention will be further described below in conjunction with accompanying drawing and embodiment: figure 1 It is a schematic diagram of the principle of the present invention.

[0018] like figure 1 As shown, the data correction method for improving measurement accuracy in this embodiment includes

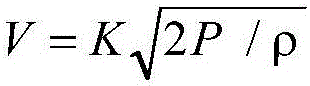

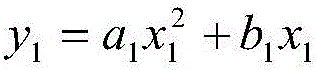

[0019] Collect continuous indirect measurement data to be corrected, and establish segmental nonlinear correction model I and segmental nonlinear correction model II,

[0020] Set the hysteresis interval q-p, where the critical threshold q<p, when the measured continuous indirect data value is less than the critical threshold p, use the segmented nonlinear correction model I for correction, when the measured continuous indirect data value increases to greater than the critical threshold When p, the piecewise nonlinear correction model II is used for correction.

[0021] When the measured continuous indirect data value increases to greater than the critical th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com