Multifunctional rock mechanics experiment cutting machine

A rock mechanics and multi-functional technology, applied in the direction of scientific instruments, stone processing tools, stone processing equipment, etc., can solve the problems of different degrees of difficulty in cutting, difficulty in clamping and positioning, waste of auxiliary time, etc., to improve the safety of use, High cutting efficiency and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

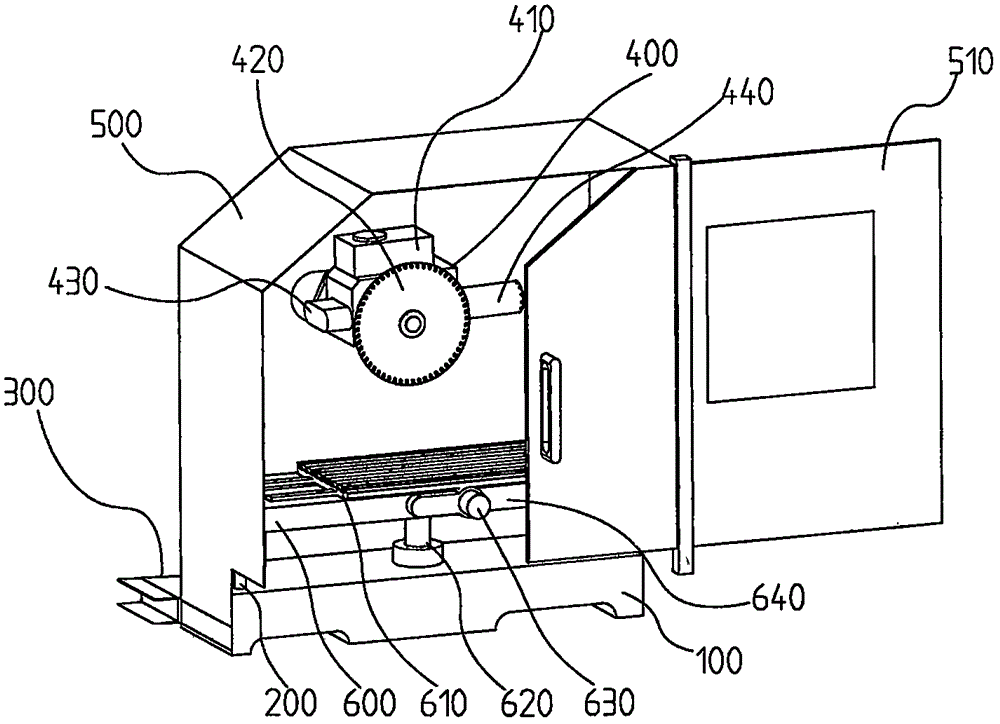

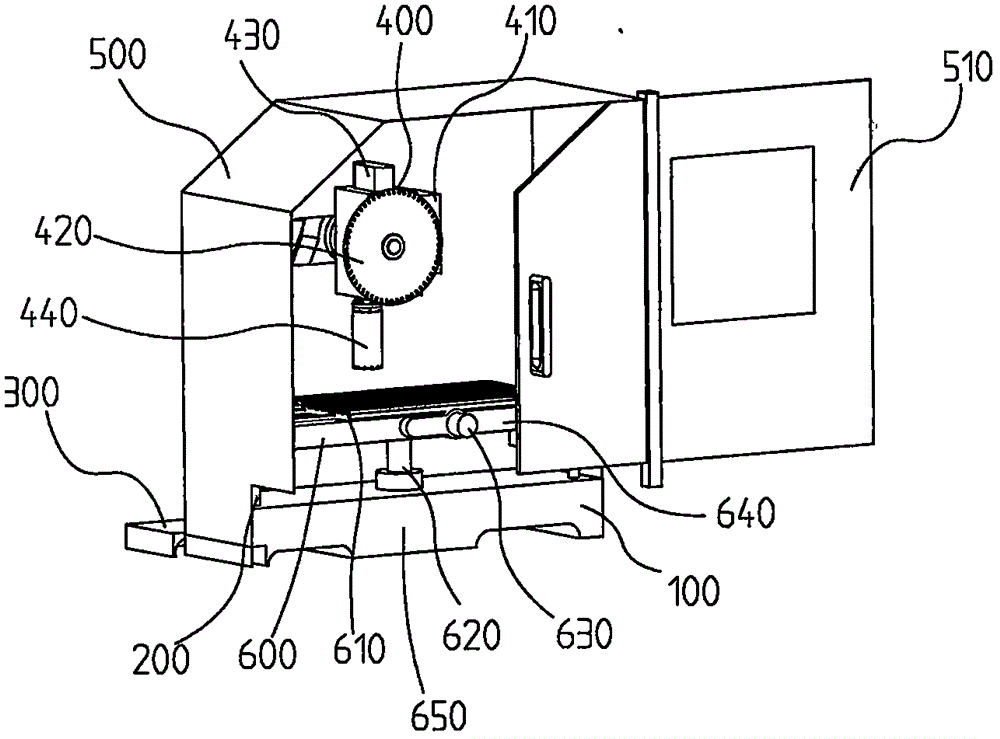

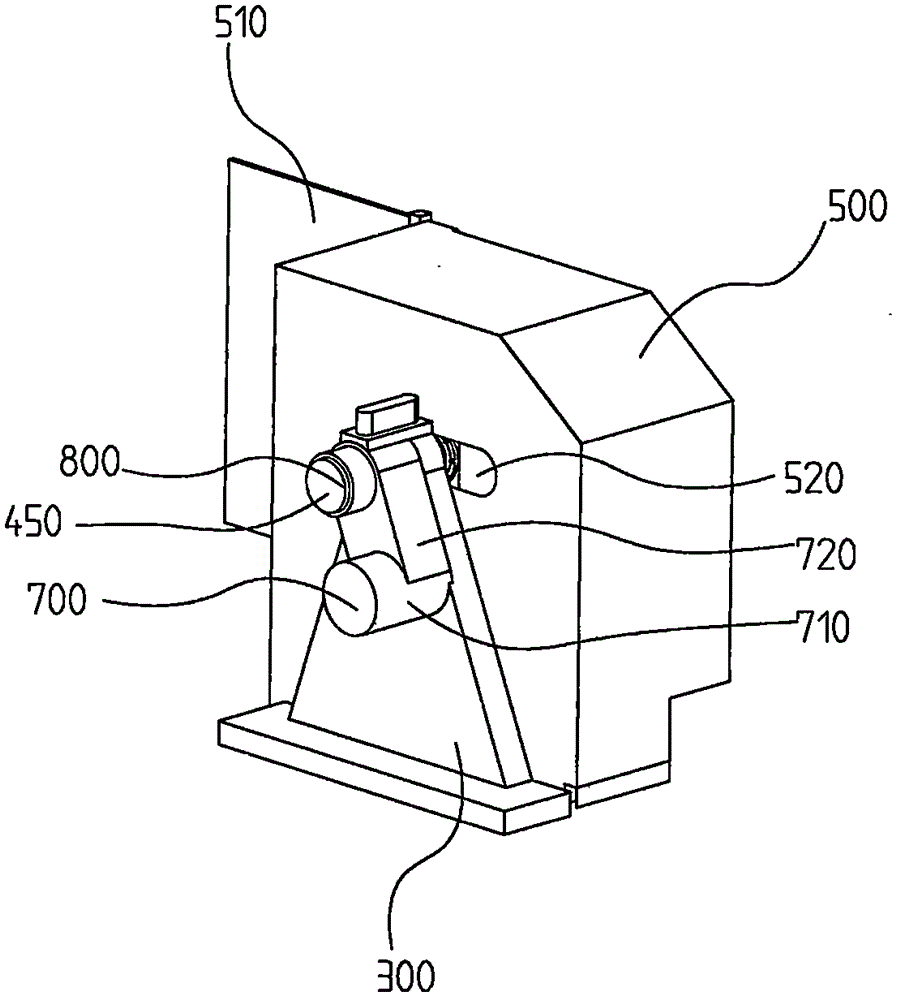

[0018] Such as Figure 1-Figure 3 as shown, figure 1 It is a schematic diagram of the structure of the cut-off use state provided by the embodiment of the present invention, figure 2 It is a schematic structural diagram of the drilling state provided by the embodiment of the present invention, image 3 It is a schematic diagram of a rear-view three-dimensional structure provided by an embodiment of the present invention.

[0019] In a specific embodiment, a multifunctional rock mechanics experiment cutting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com