A bidirectional free-rotating rock coring machine base and sampling method

A technology of coring machine and rotating support, applied in the direction of sampling device, etc., can solve the problems of complex cost, difficulty, difficulty of similarity ratio, etc., and achieve the effects of high drilling accuracy, simple instrument manufacture, convenient and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

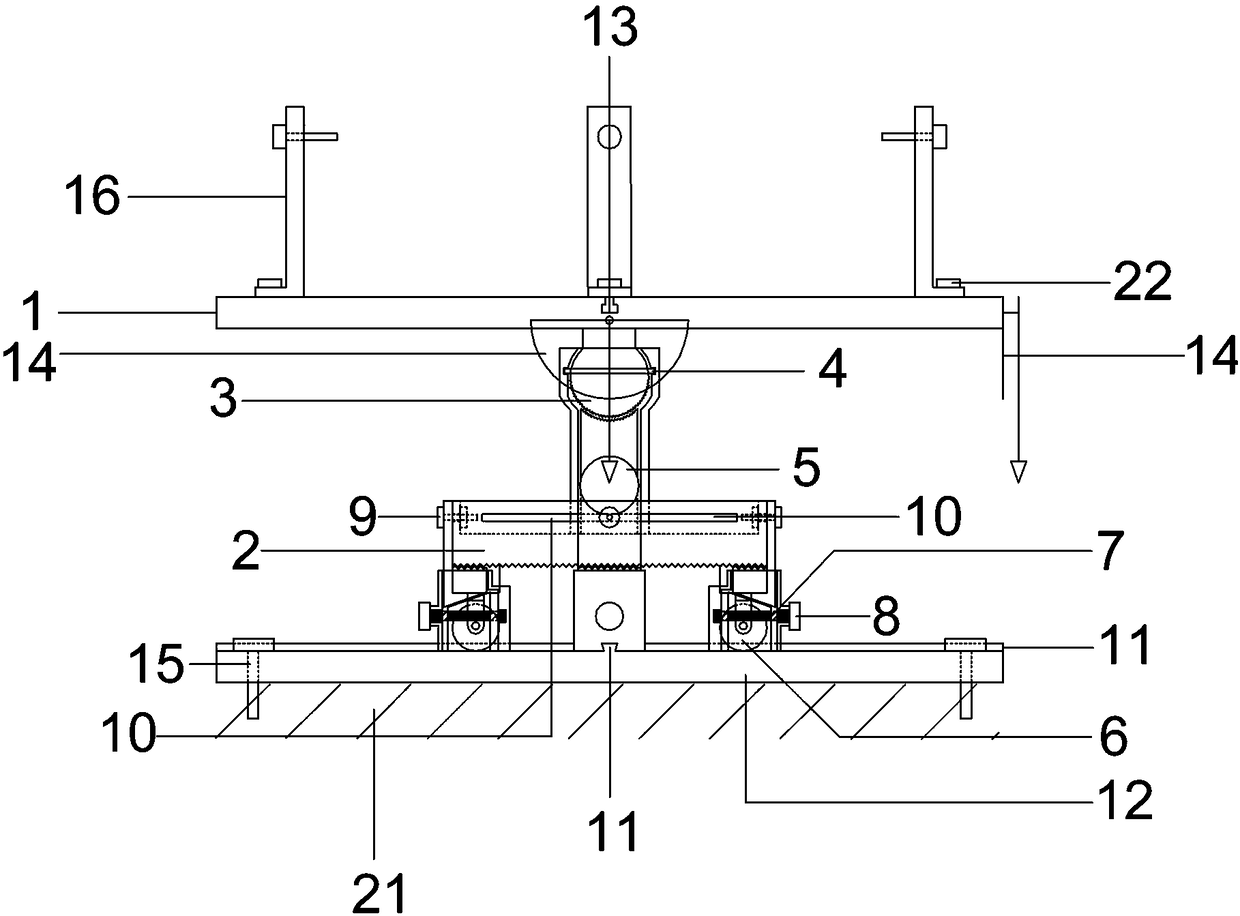

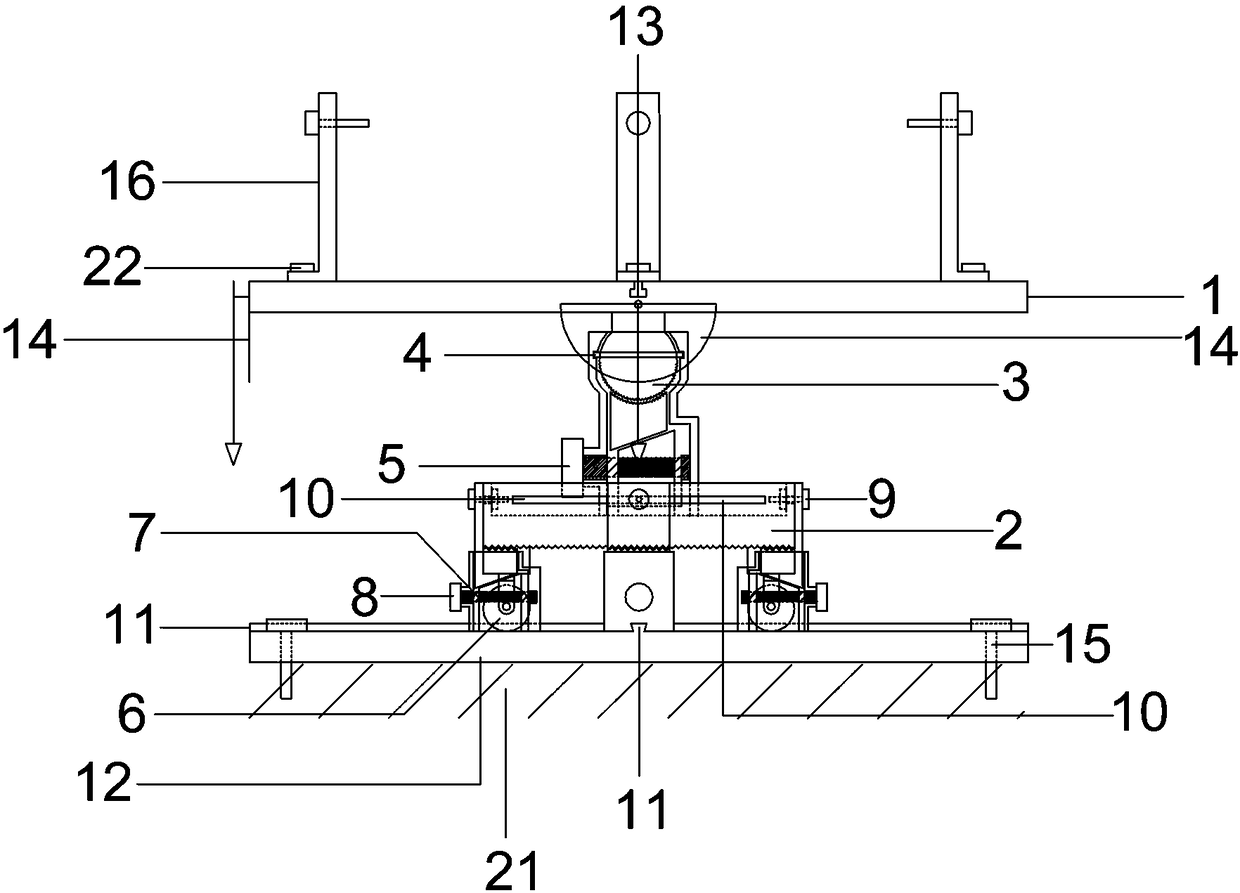

[0057] see Figure 1-21 , a base of a bidirectional free-rotating rock coring machine, which includes a rotating rock sample tray structure, a spherical hinge support structure, a movable chassis structure and a bottom plate structure.

[0058] Further, the base plate structure includes a support base plate 12 , the support base plate 12 is fixed on the base plate foundation 21 through bolts 15 , and the upper surface of the support base plate 12 defines cross guide rails 11 .

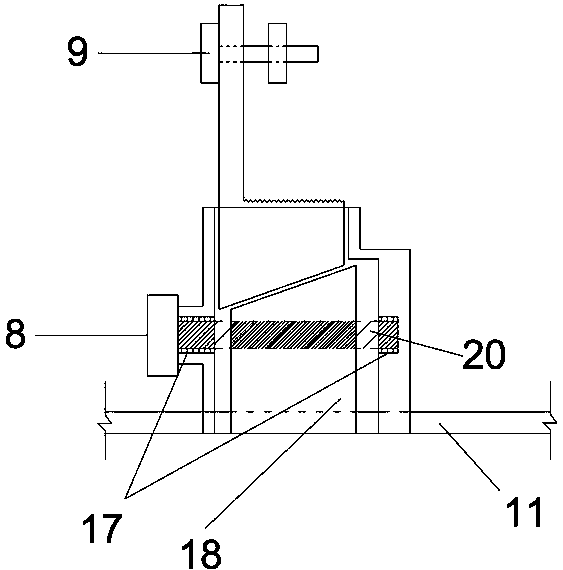

[0059] Further, the movable chassis structure includes a movable bottom plate fixed support 7, the movable bottom plate fixed support 7 is fixed on the support bottom plate 12 through the guide rail 11, and the top of the movable bottom plate fixed support 7 supports the rotating support fixed chassis 2, And through the set bolt 9 and the bolt hole 10, the rotating support fixed chassis 2 is laterally fixed.

[0060] Further, the spherical hinge support structure includes a spherical hinge 3, the uppe...

Embodiment 2

[0067] A rock sampling method is carried out at the base of a bidirectional free-rotating rock coring machine, which includes the following steps:

[0068] S1: First move the fixed chassis 2 of the rotary support, move the fixed chassis of the rotary support to a suitable position on the bottom plate 12 of the support through the roller 6, so that the drill bit of the drilling machine is roughly aligned with the center of the rotary rock sample tray 1, Then four movable floor fixed supports 7 are pushed into the surroundings of the rotary support fixed chassis 2 along the guide rails 11 on the support bottom plate 12, so that the scratched contact surface on the movable floor fixed support 7 is fixed with the rotary support. The lower surface of the chassis 2 is completely fitted, and the No. 1 rotating disk 8 is rotated to lock the four movable bottom plate fixing supports 7 respectively;

[0069] S2: Then pass the fastening bolts 9 on the fixed support 7 of the four movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com