A spring cable for charging pile of new energy electric boat

A technology for spring cables and electric boats, applied in the direction of power cables, insulated cables, and extendable conductor cables, etc., can solve problems such as loss of spring steel wires, displacement of connecting parts, separation of spring steel wires and cable cores, and achieve easy manufacturing and use , improve the service life, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

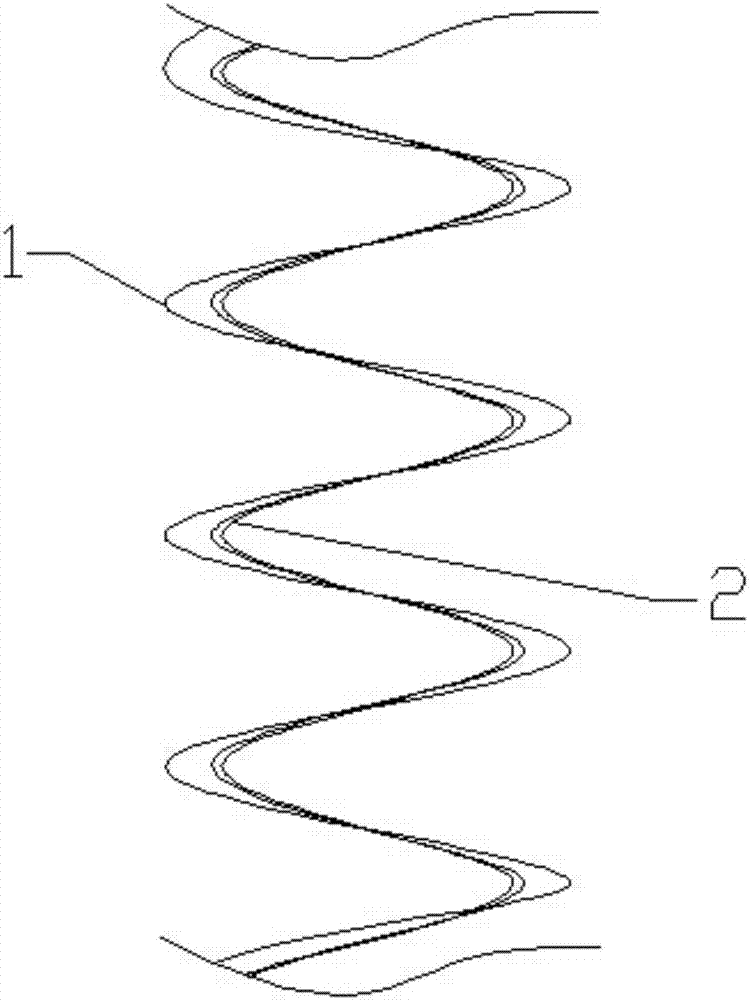

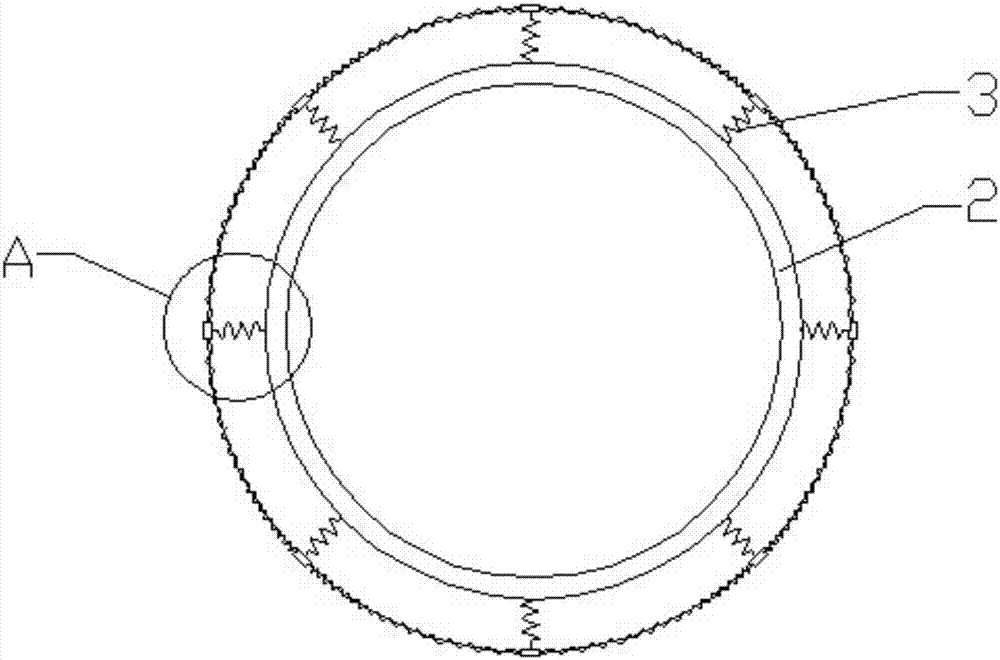

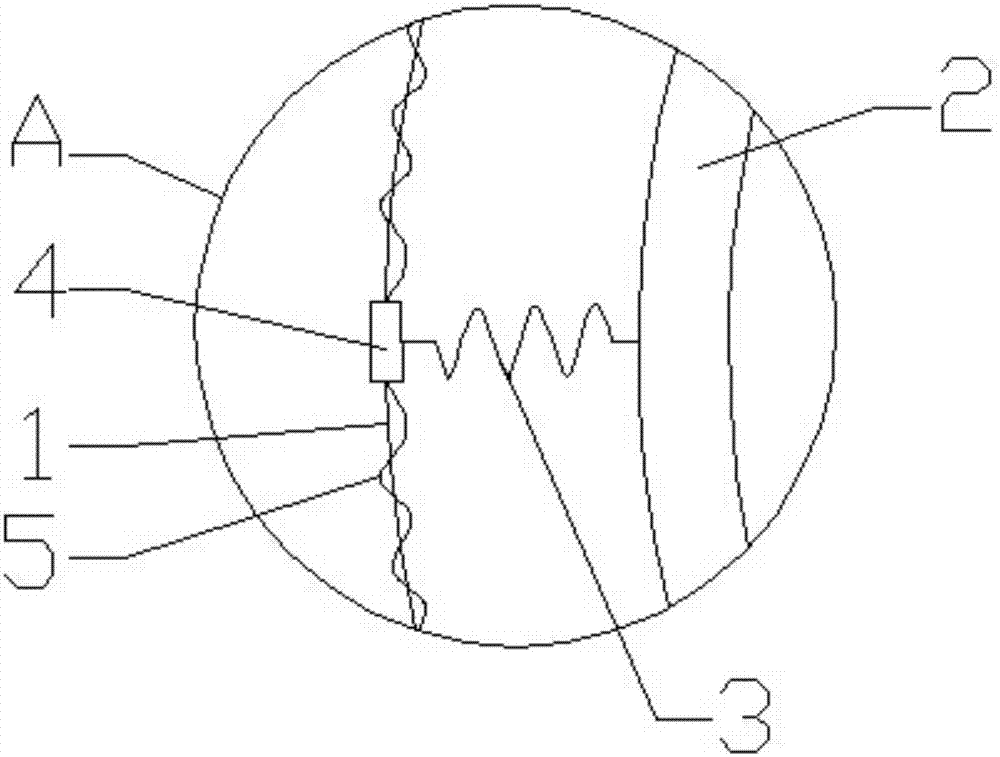

[0025] refer to Figure 1-4 , a spring cable for a new energy electric boat charging pile, including a cable 2, a spring 1 and a connector, the cable 2 is arranged in the inner circle of the spring 1, and the two are connected by a plurality of equally spaced connections The connector realizes sliding connection, the connector includes spring two 3 and sliding sleeve 4, the sliding sleeve 4 is sleeve-shaped, and spring one 1 passes through the inner circular hole of the sleeve-shaped sliding sleeve 4, and the outer surface of the sliding sleeve 4 is also A spring two 3 is fixed; the cable 2 includes a sheath 22 and a plurality of steel strips 23 equidistantly sheathed on the sheath 22, and the other free end of the spring two 3 is fixedly connected to the steel strip 23 , the connecting points of both ends of the cable 2 and the spring one 1 are the same.

[0026] It should be noted that a spring three 5 is also connected between the adjacent connectors, and the spring one 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com