Manufacturing method of 3D (three-dimensional) lithium batteries

A manufacturing method and technology of lithium batteries, applied in the direction of electrolytic storage battery manufacturing, primary batteries, and equipment for manufacturing primary batteries, etc., can solve the problems of low efficiency and high cost of three-dimensional lithium battery technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

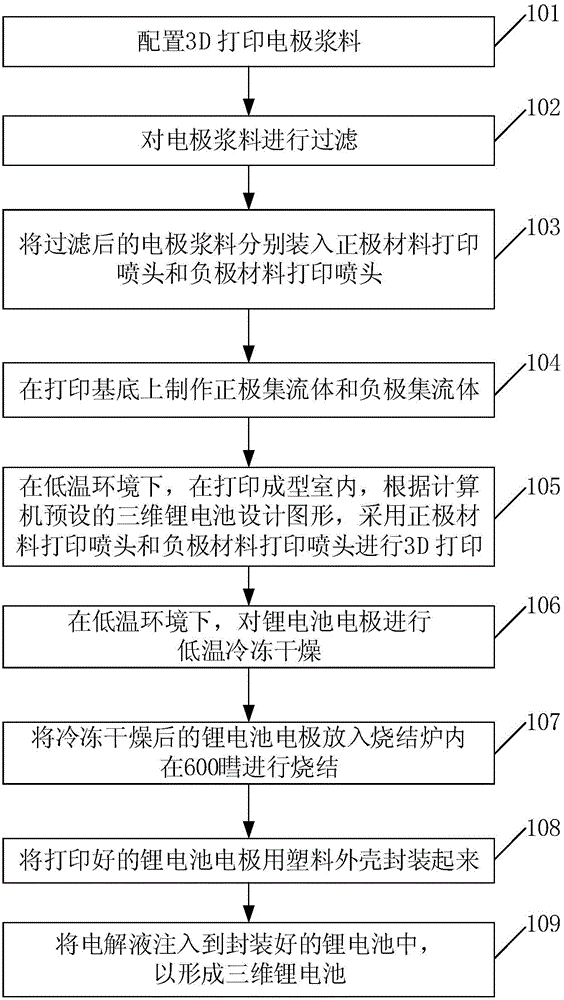

[0021] Such as figure 1 As shown, a method for manufacturing a three-dimensional lithium battery provided by an embodiment of the present invention includes:

[0022] Step 101, configuring 3D printing electrode paste;

[0023] Among them, the cathode material powder (such as LiCoO 2 、LiFePO 4 , LiMn 2 o 4) and anode material powders (such as Li 4 Ti 5 o 12 , graphite) and organic solvent (1,4 dioxane), conductive agent (carbon black) and thickener / binder (polyvinyl alcohol PVA, sodium carboxymethyl cellulose CMC, etc.) according to the mass fraction Mix evenly, wherein the mass fraction of the electrode active material is 50%-80%, the mass fraction of the organic solvent is 20%-50%, the mass fraction of the conductive agen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap