motor

A motor and cage technology, applied in the direction of electromechanical devices, electrical components, windings, etc., can solve the problem of assembling motors with a lot of effort, and achieve the effect of high-efficiency electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] Hereinafter, modes for implementing the present invention will be described with reference to the drawings.

[0091] (the whole frame)

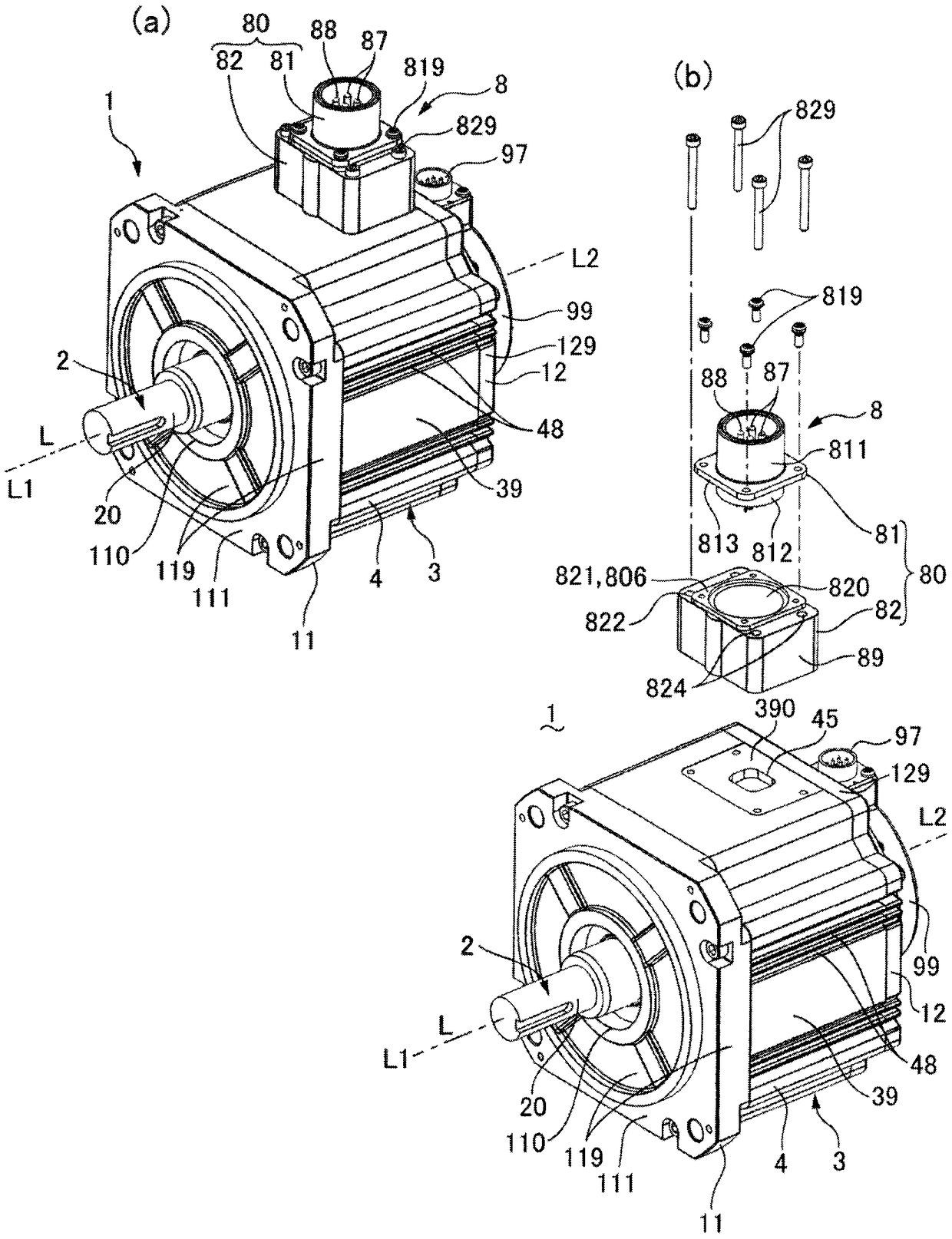

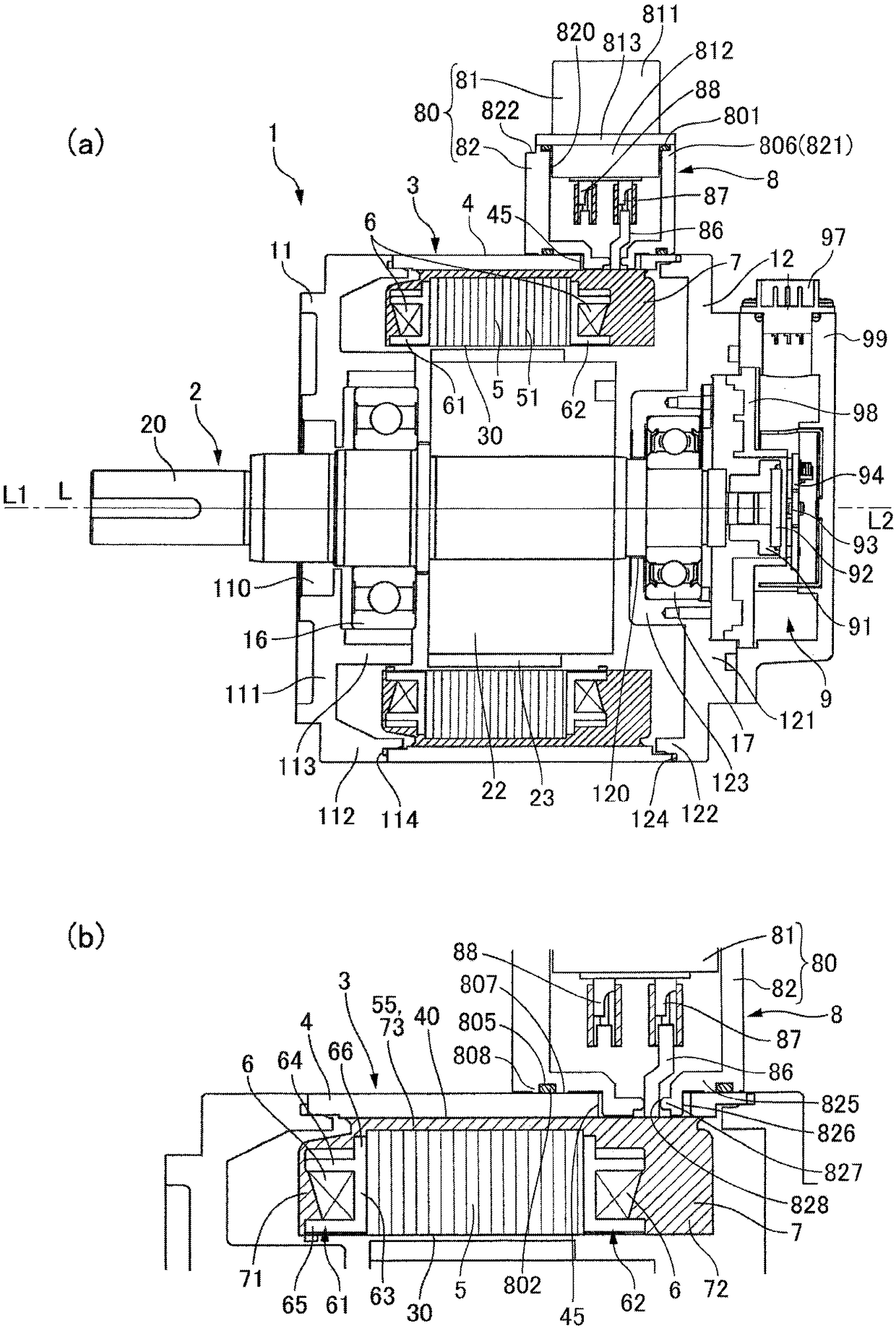

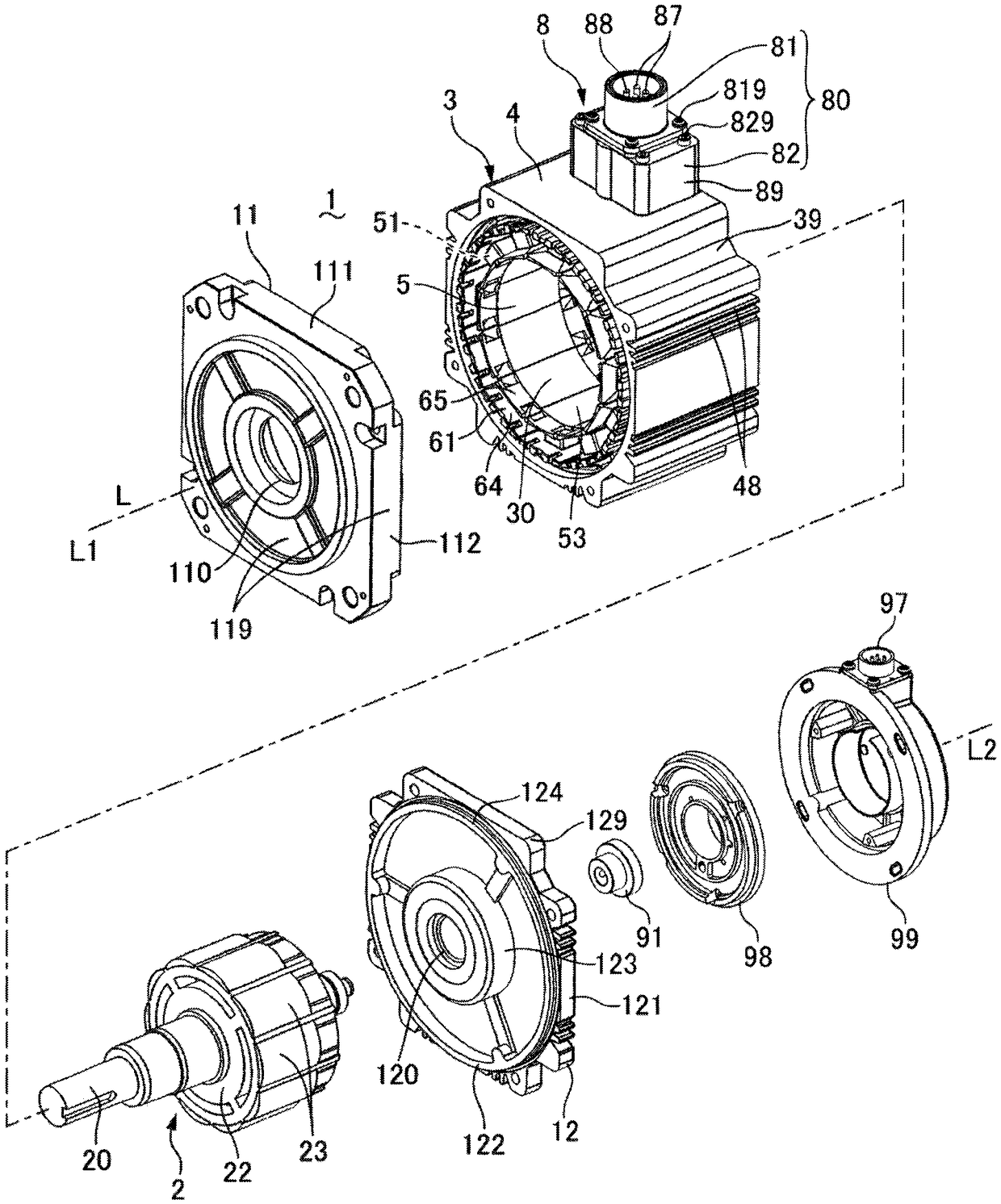

[0092] figure 1 (a), figure 1 (b) is a perspective view of the motor 1 to which the present invention is applied viewed from the output side, figure 1 (a) is a perspective view of the whole motor 1, figure 1 (b) is a perspective view of the state which removed the power supply part 8 from a motor main body. figure 2 (a), figure 2 (b) is a cross-sectional view showing a state where the motor 1 to which the present invention is applied is cut at a position where the motor axis passes. image 3 It is an exploded perspective view of the motor 1 to which the present invention is applied. In addition, in image 3 In , illustration of the molded resin portion 7 is omitted.

[0093] figure 1 (a), figure 1 (b), figure 2 (a), figure 2 (b) and image 3 The motor 1 shown is a permanent magnet type synchronous motor. The motor 1 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com