Micromechanical sensor

A micromechanical sensor, micromechanical technology, applied in instruments, microstructure technology, electric solid devices, etc., can solve problems such as sensor enlargement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

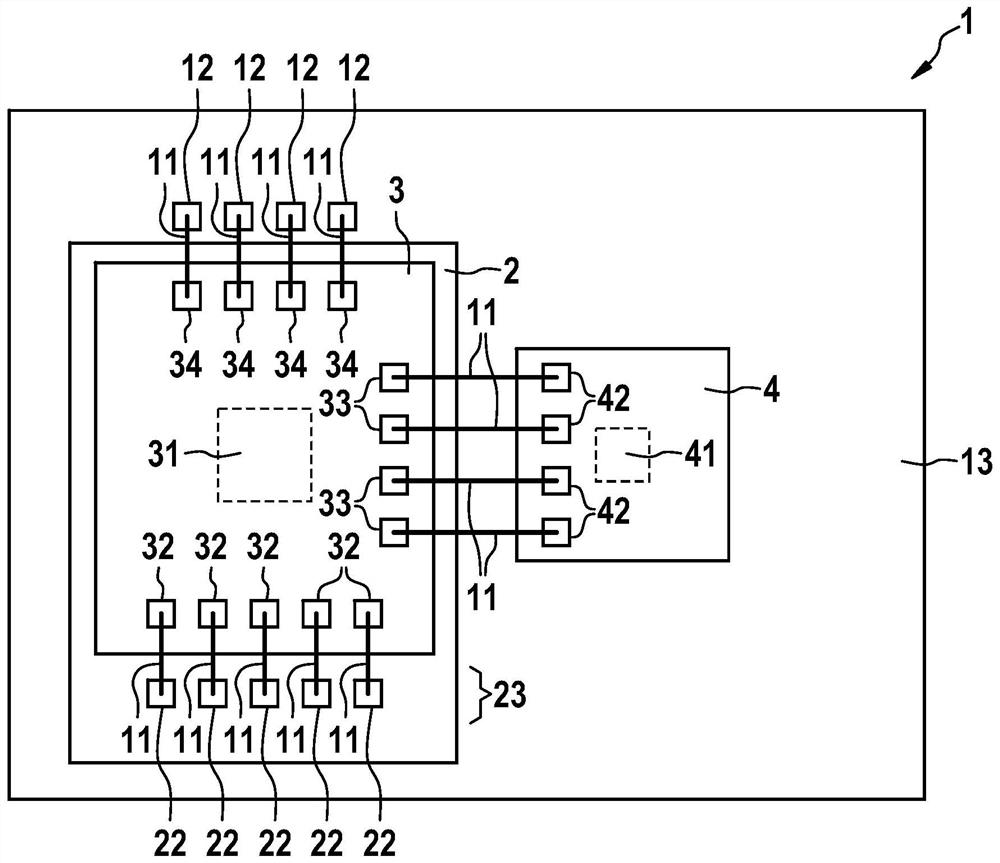

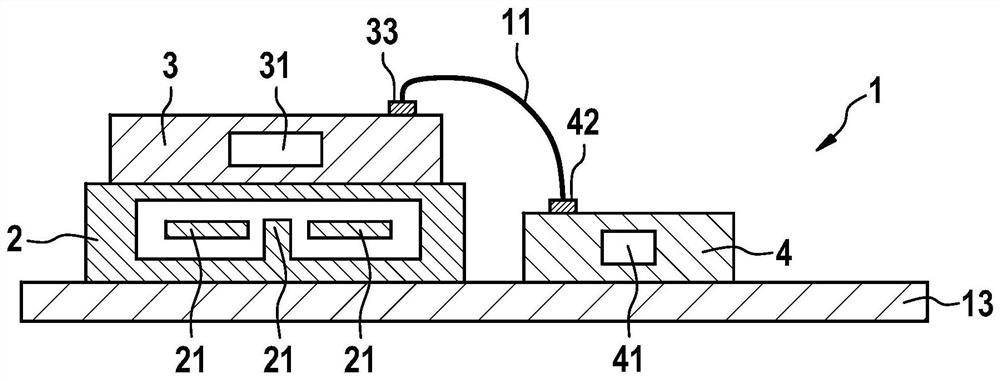

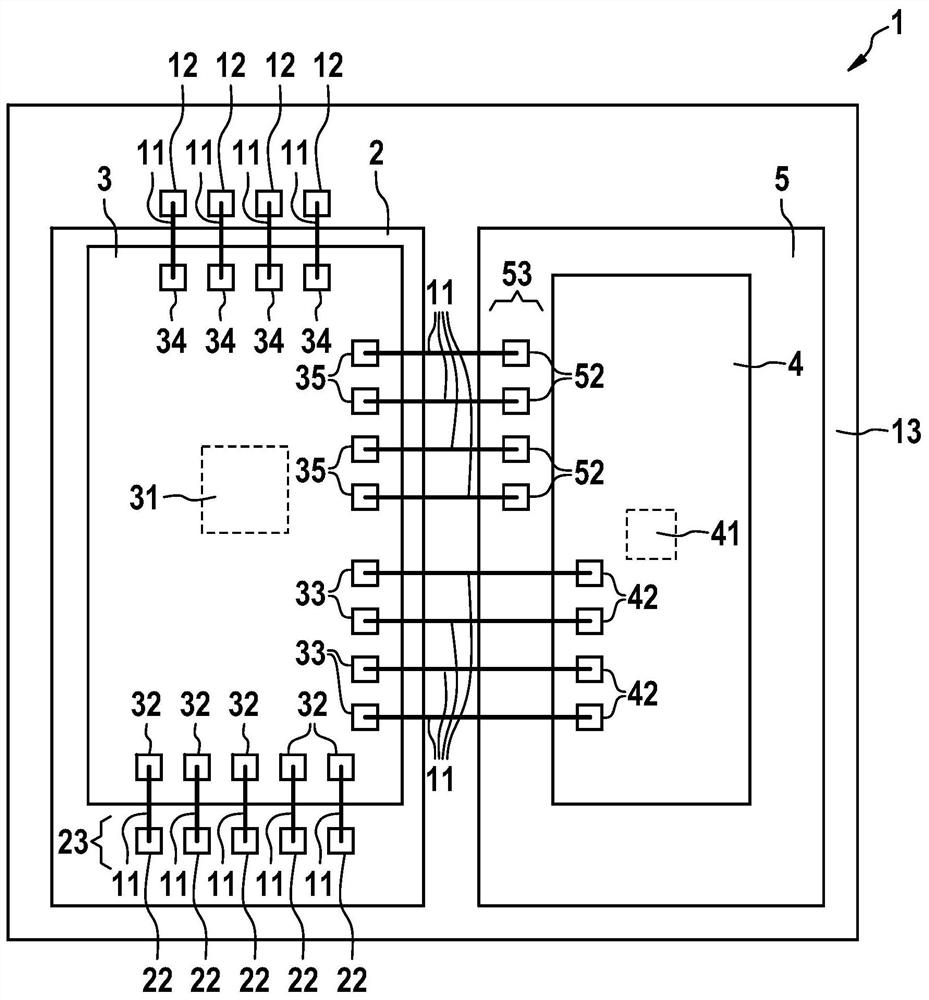

[0027] figure 1 A micromechanical sensor 1 is shown, which has a micromechanical chip 2 with a first micromechanical structure, which also has a first evaluation chip 3 and a second evaluation chip 4 , The first analysis and processing chip has a first application specific integrated circuit 31 , and the second analysis and processing chip has a second application specific integrated circuit 41 . The micromechanical chip 2 is arranged here on an optional substrate 13 . The first evaluation chip 3 and the micromechanical chip 2 are arranged one above the other, ie stacked on top of each other. The micromechanical chip 2 is electrically conductively connected to the first evaluation chip 3 . The connection is at figure 1 The process is carried out by means of bonding wires 11 leading from the chip pad 22 of the micromechanical chip 2 to the chip pad 32 of the first evaluation chip 3 . It is also possible to provide other conductive connections (e.g. via vias or direct bondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com