Container for fuel cell, fuel cell and electronic device

A fuel cell and container technology, which is applied to fuel cells, fuel cell components, solid electrolyte fuel cells, etc., can solve the problems of hindering the electrochemical reaction of electrolyte components 23, difficult to realize small fuel cells, and deterioration of power generation efficiency. Improve mechanical reliability, high reliability and safety, good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

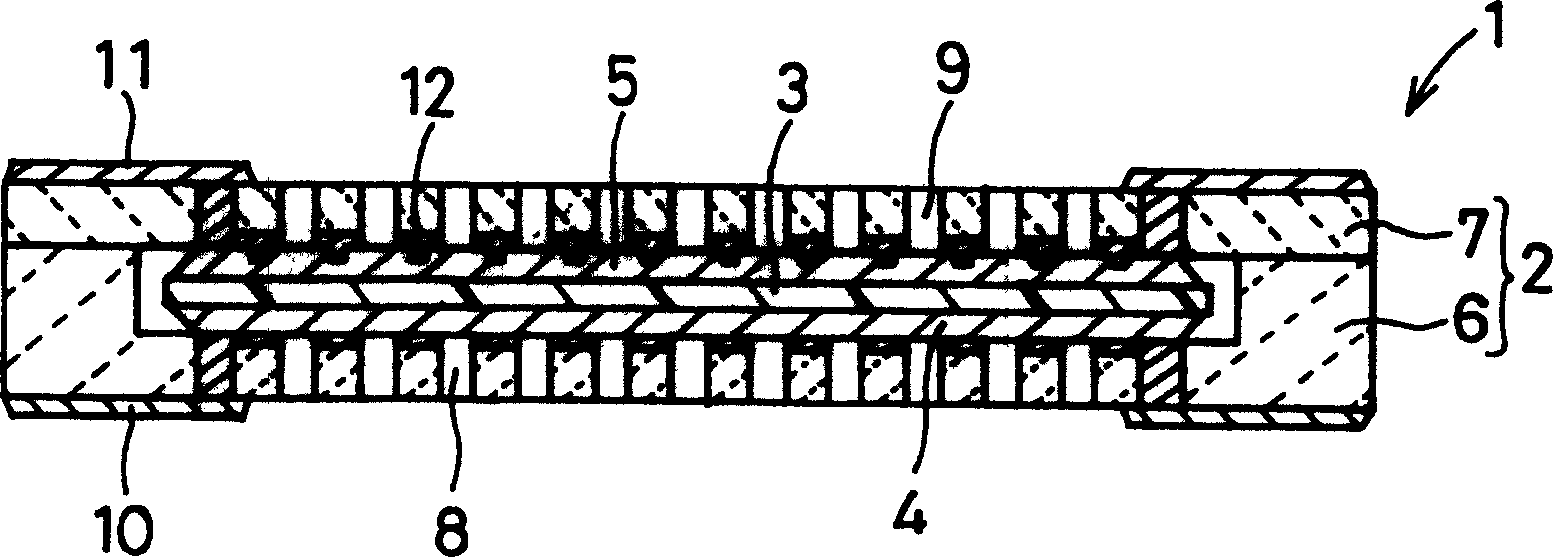

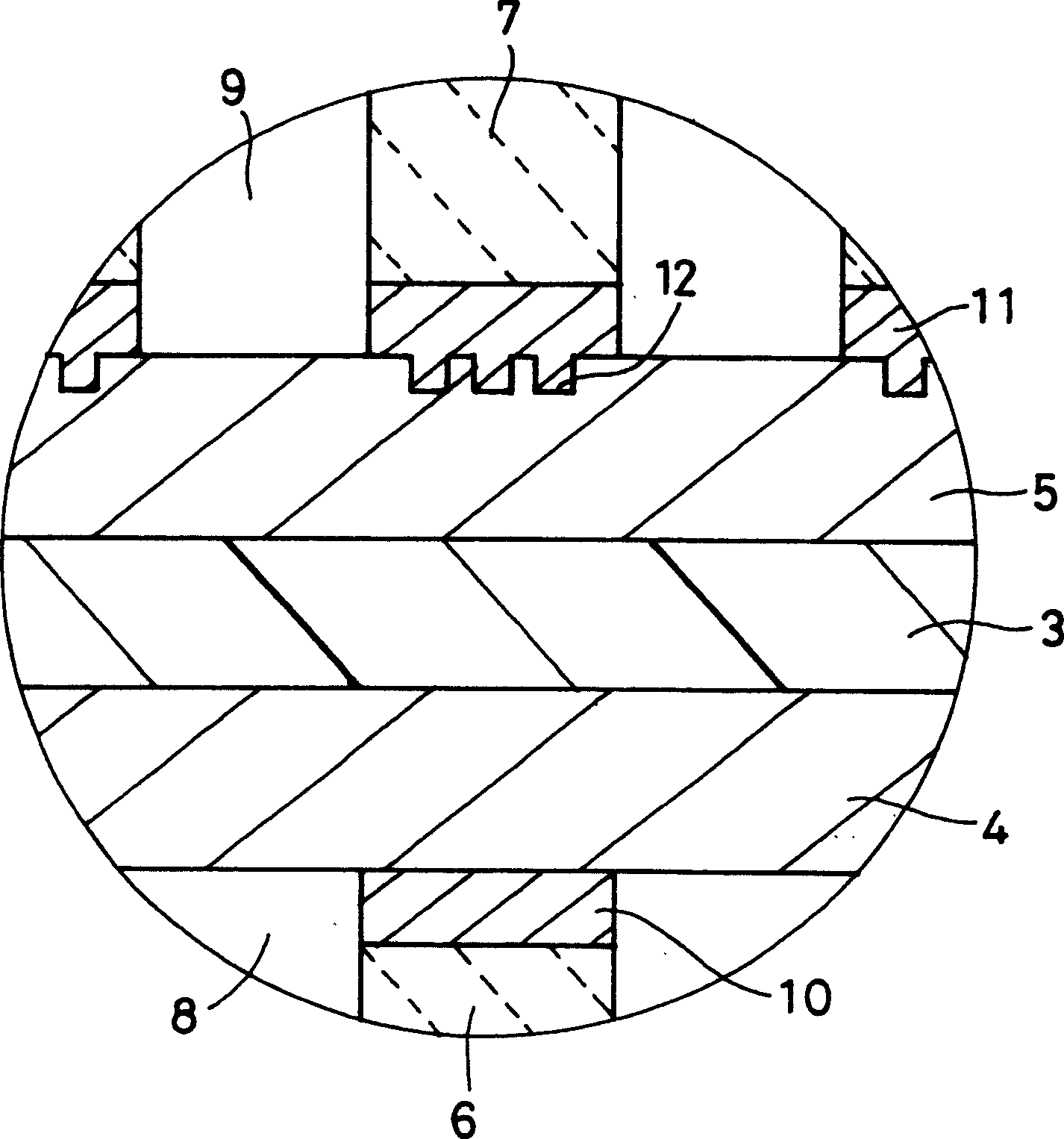

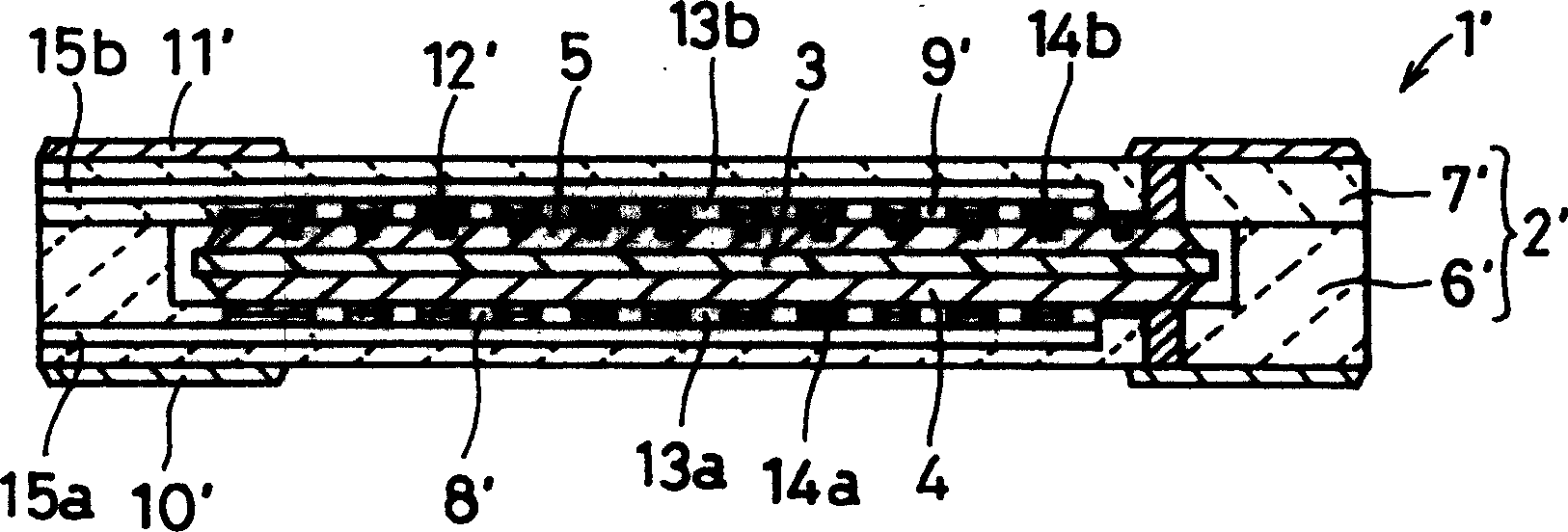

[0060] The fuel cell container and fuel cell of the present invention will be described in detail below with reference to the drawings. figure 1 Is a cross-sectional view showing an example of an embodiment of a fuel cell using the fuel cell container of the present invention, figure 2 Yes figure 1 Enlarged view of the main part. In these figures, 1 is a fuel cell, 2 is a fuel cell container, 3 is an electrolyte component, 4 is a first electrode, 5 is a second electrode, 6 is a substrate, 7 is a cover, and 8 is a first fluid flow path , 9 is a second fluid flow path, 10 is a first wiring conductor, 11 is a second wiring conductor, and 12 is a pit.

[0061] and, figure 1 It shows a fuel cell in which a pit 12 is formed at each contact portion of the second electrode 5 and the lid 7, respectively, figure 2 This shows a fuel cell in which three pits 12 are formed in each contact portion of the second electrode 5 and the lid 7.

[0062] In the electrolyte member 3, a fuel electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com