Parking brake interlock for automatic lift axle

A parking brake, automatic technology, used in brakes, motor vehicles, brake safety systems, etc., can solve problems such as reduced tire life, tire wear, and fuel economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments disclosed herein are to provide a description of the present subject matter, and it should be understood that the subject matter may be embodied in various other forms and combinations not shown in detail. Accordingly, the specific embodiments and features disclosed herein are to be construed as limiting the subject matter as defined in the appended claims.

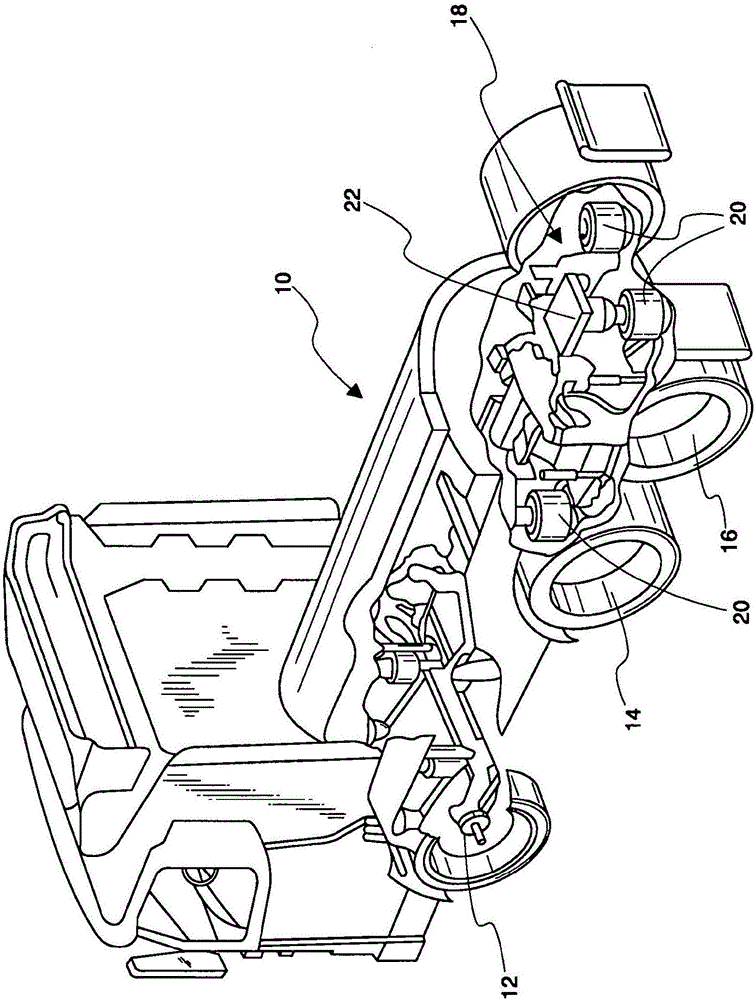

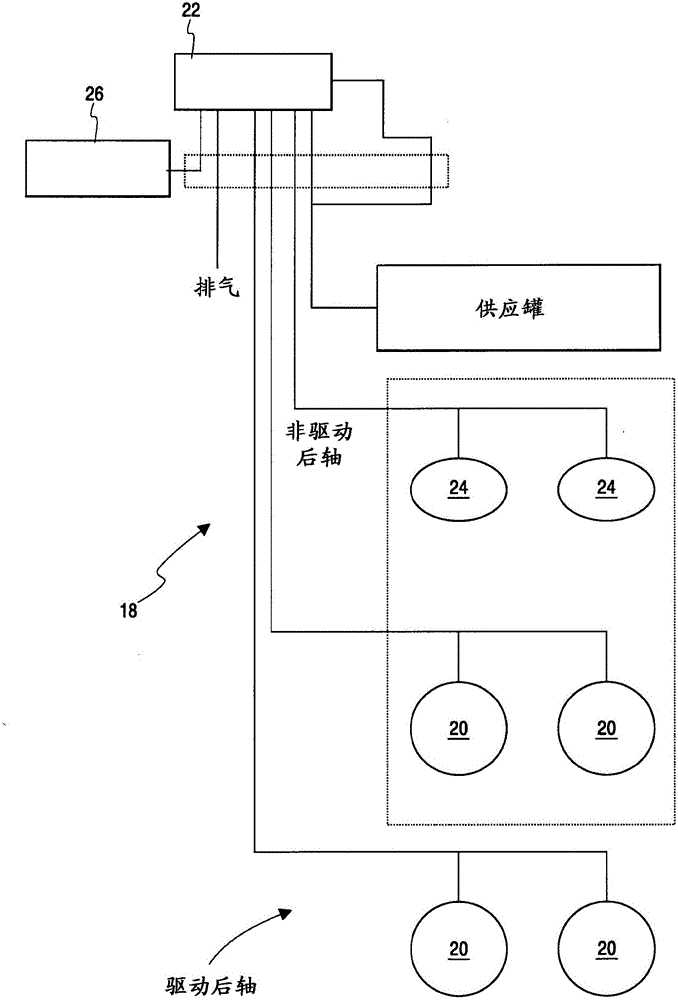

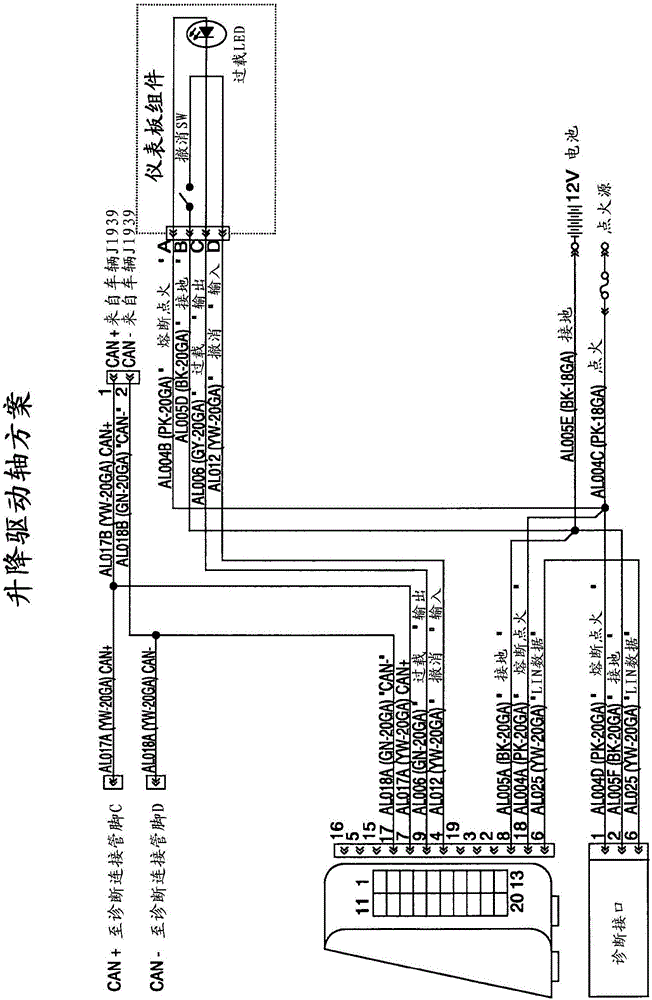

[0021] figure 1 A vehicle 10 is shown having a front axle 12 and two rear axles 14 and 16 . In a preferred embodiment, the vehicle 10 has a 6x2 configuration in which one of the rear axles and the front axle 12 are non-driven and the other rear axle is driven. Preferably, the forwardmost rear axle 14 is a non-driven axle, which is selectively movable into and out of contact with the ground, and the rearmost rear axle 16 is a driven axle. It is also within the scope of the invention that the forwardmost rear axle 14 be a drive axle and that the rearmost rear axle 16 be a non-driven support axle.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com