Compressing device for grass baling machine

A technology of a pressing device and a pressurizing device, which is applied in the field of agricultural equipment, can solve the problems of low baling density, inconvenient storage and transportation, and loose molding, and achieves good effect and good extrusion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

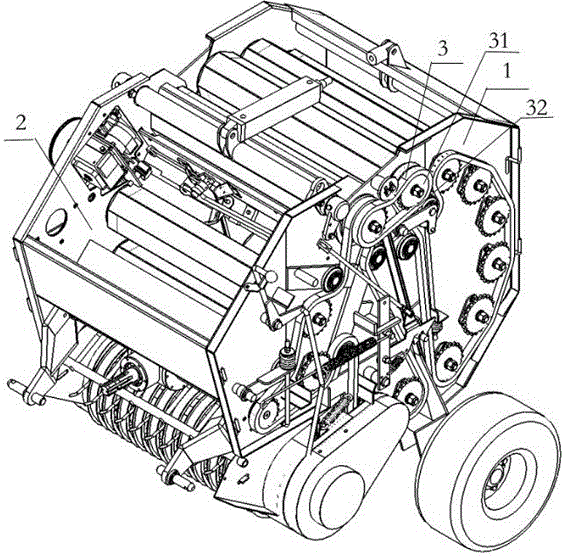

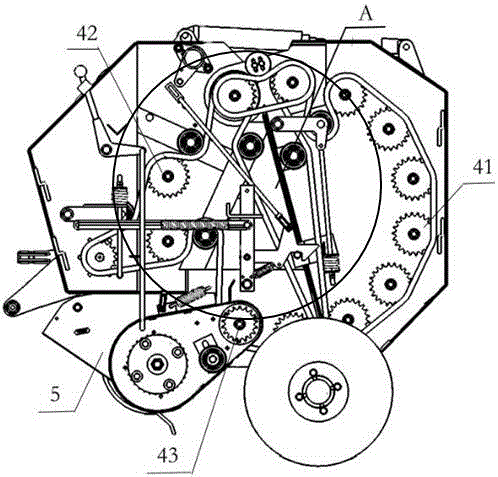

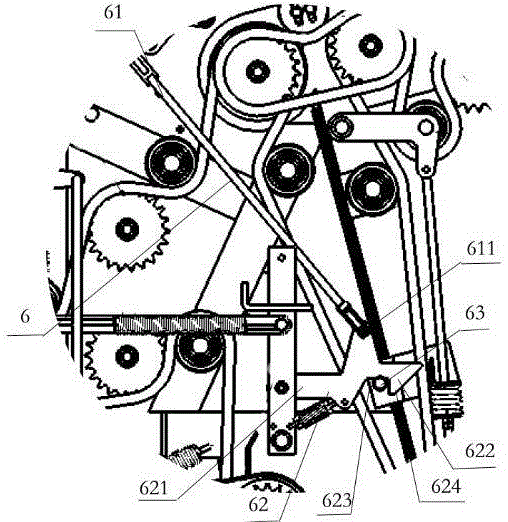

[0035] Example 1, such as figure 1 — Figure 5 Shown: a pressing device for a baler, including a box body 1, the box body includes a front box body 2 close to the feeding device 5 and a rear box body 1 away from the feeding device 5, the front box body 2 and the rear box body The bodies 1 are hinged to each other to jointly form a molding cavity for accumulating straw. The feeding device 5 includes a passage port for materials to enter the molding cavity; Wheel 41, auxiliary pinch wheel 42 and guide wheel 43, main pinch wheel 41 is located on rear box body 1 inner wall, secondary pinch wheel 42 is located on the front box body 2, and guide wheel 43 is located on the feeding device 5, It is used to guide the straw from the feeding device 5 to the forming cavity; the main pressing wheel 41 includes a plurality of flat pressing surfaces 411, and the flat pressing surfaces 411 are provided with a booster device 412 and an anti-skid groove 413.

[0036] Straw enters feeding devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com