A method for robot safety level assessment

A safety level, robot technology, applied in the field of level assessment, can solve problems such as the immediate stop of dangerous movements of machines, reduce or eliminate risks, improve the level of intrinsic safety, and promote safe production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] The safety PLC (L) module used in the robot control cabinet is PSR-SPP-24DC / TS / S, the PLs level is e, and the safety integrity level is SIL level SIL3; the safety output module (O) module in the control cabinet is PSR-SCP-24DC / FSP / 2X1 / 1X2, PLs level is e, SIL level is SIL3.

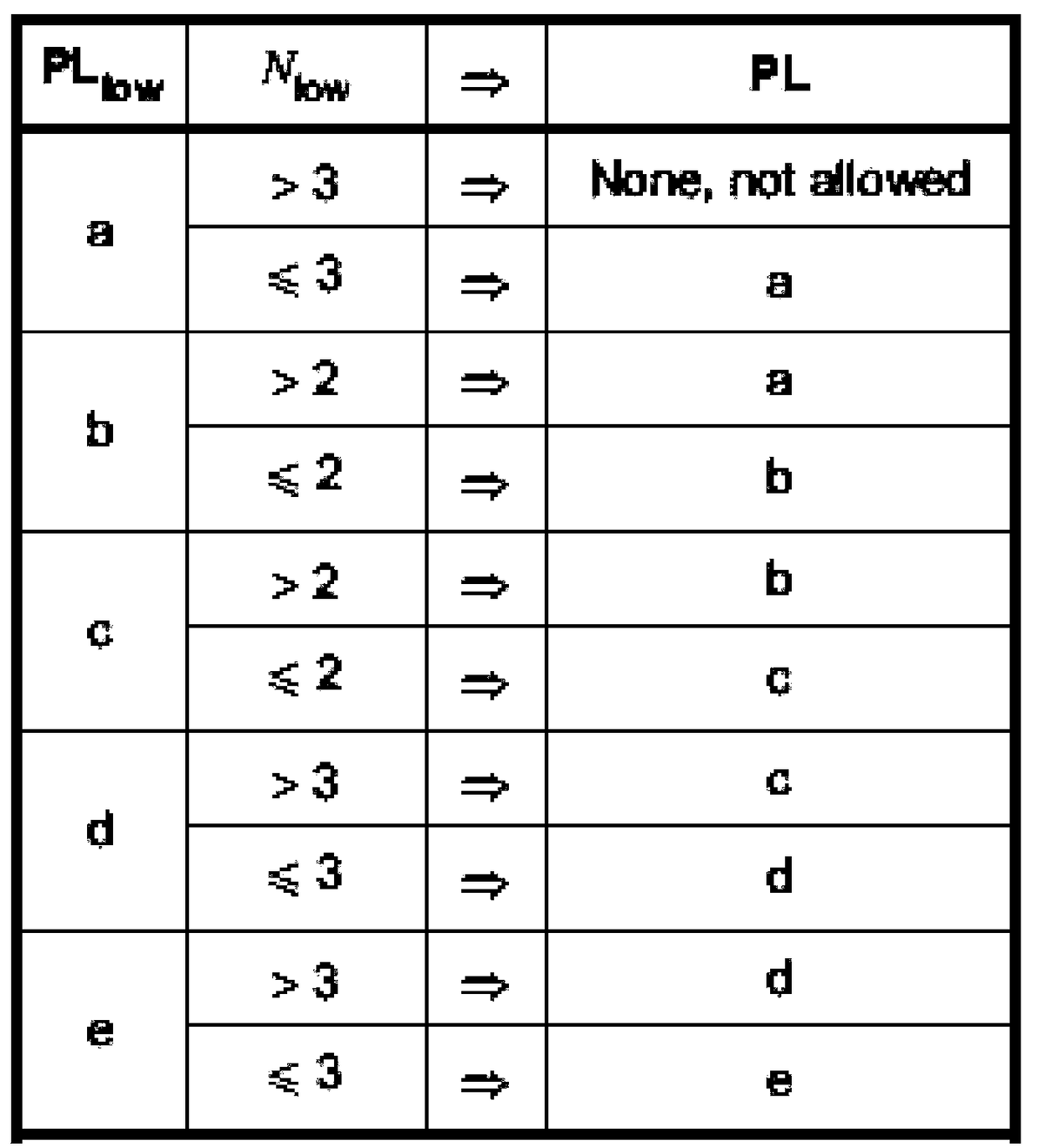

[0043] If this set of robots is used to integrate applications, and the performance level (PLr) of the complete set of equipment is d, then the number of input devices (safety door switches, safety light curtains, safety mats) at this time is 3, refer to figure 1 In the table in , the performance level PL found is at least d.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com