On-machine measuring device and measuring method applicable to energetic rotating parts

A technology for measuring devices and rotating parts, applied in mechanical measuring devices, measuring devices, mechanical diameter measurement, etc., can solve problems such as lack of technical scalability, difficulty in automatic realization, difficulty in multi-feature centralized measurement, etc., to achieve the improvement of essential safety The effect of level, low cost and functional integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

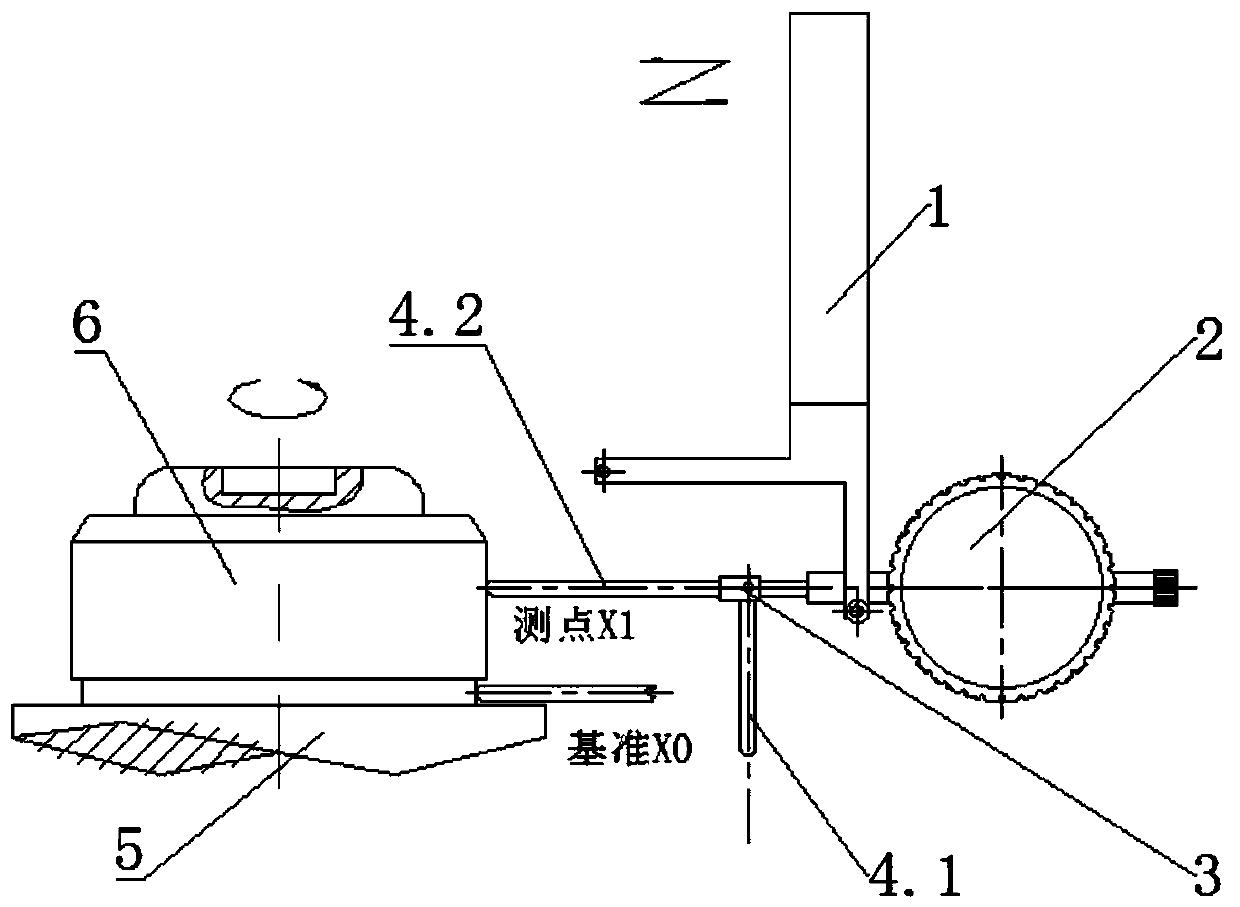

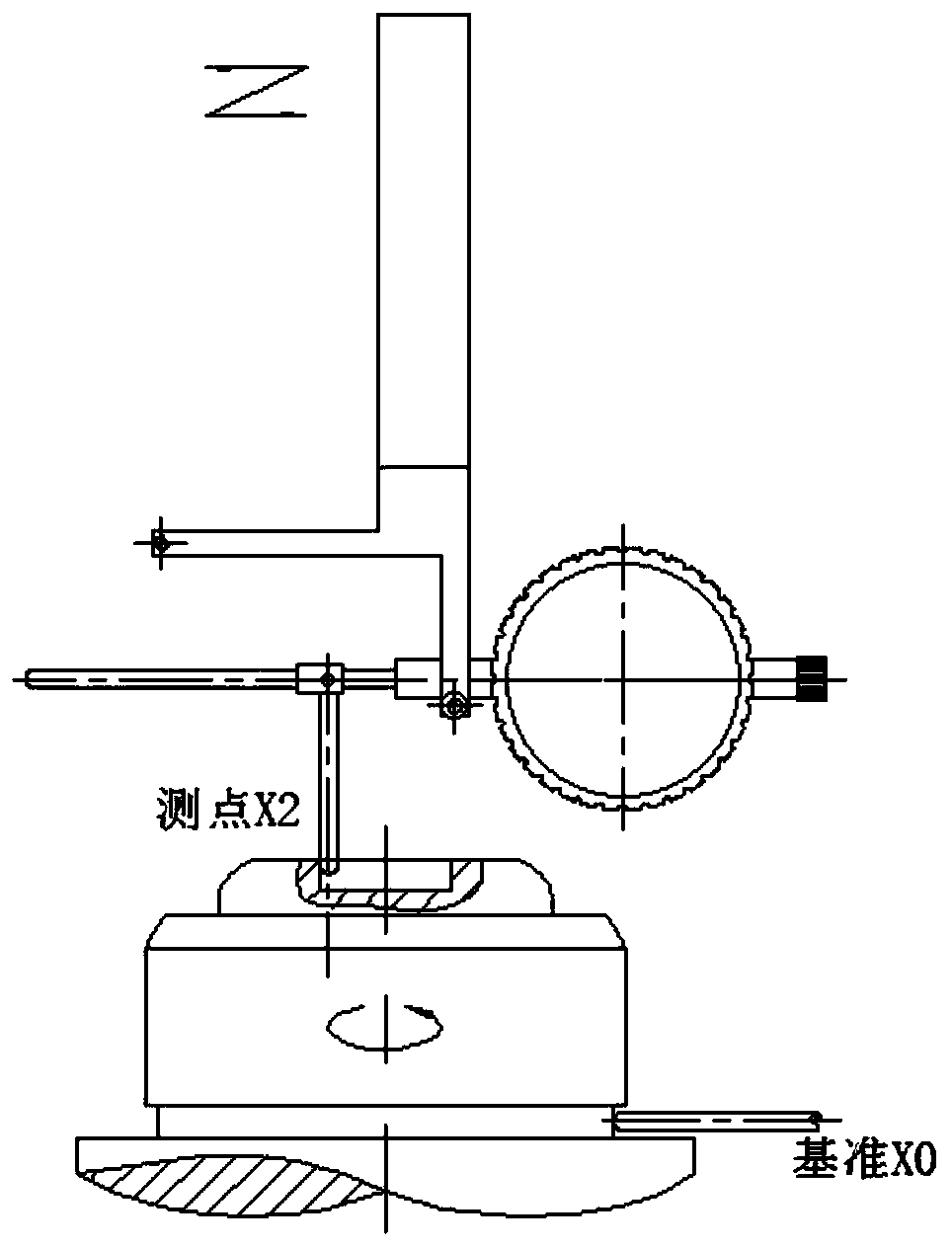

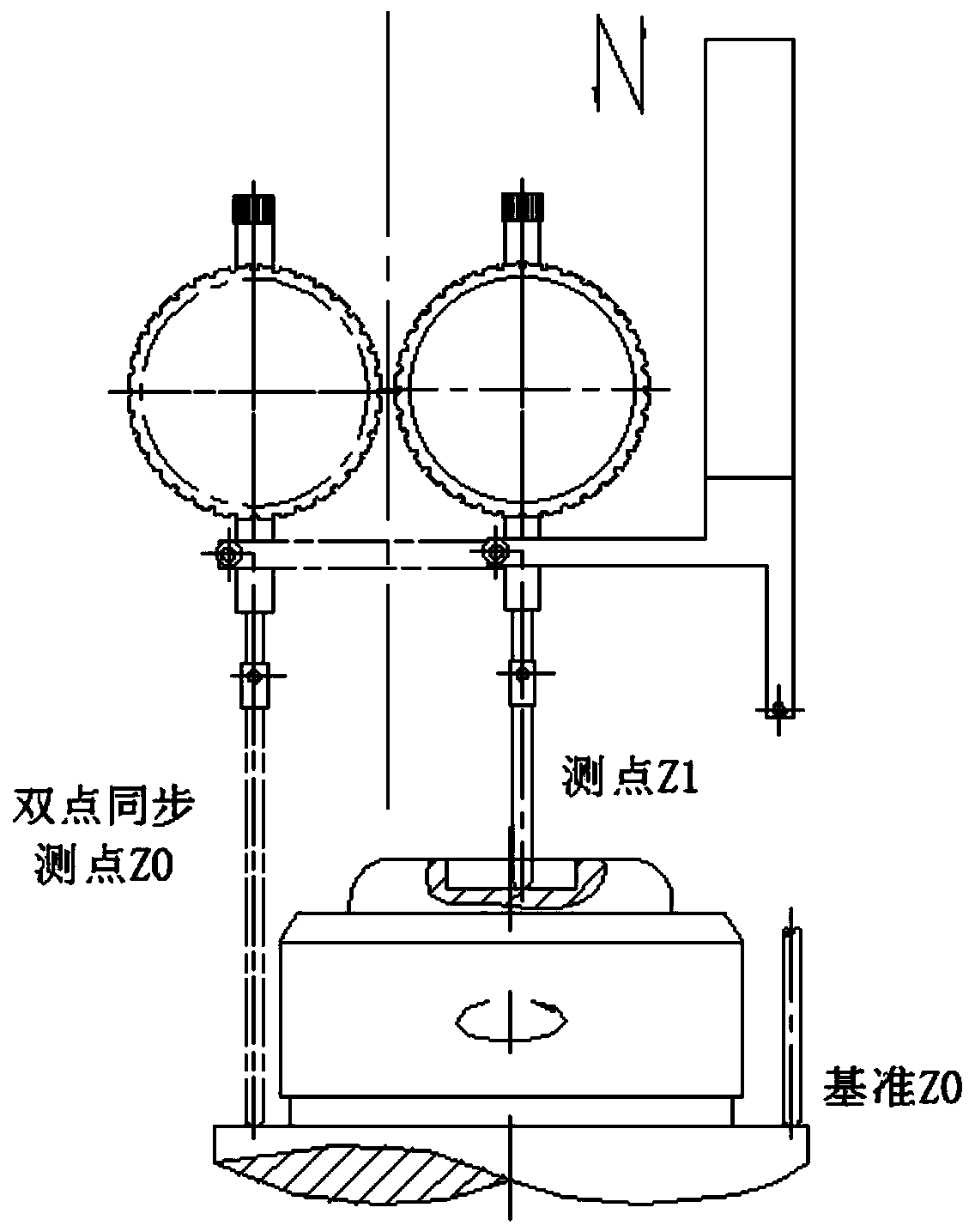

[0042] Such as Figure 1-3 As shown, based on the principle of error separation and the method of datum transformation, the adapter 3, the dial indicator 2 and the standard tool holder are integrated and designed, and the on-site precise measurement function of the rotating parts is realized by the machine tool numerical control system. An on-machine measuring device suitable for rotating parts with energy, including a suction cup 5 for absorbing a workpiece 6, and also includes a table frame 1, a measuring instrument, an adapter 3, and a stylus. The table frame 1 adopts a standard tool holder design, It can be freely installed and used on various CNC lathes, and a vertical part and a horizontal part for flexible clamping of the dial gauge 2 are provided at the execution end of the cutter bar. The execution end of the table frame 1 can flexibly hold the measuring instrument along the vertical and horizontal directions respectively, and the stylus includes a vertical stylus 4.1...

Embodiment 2

[0046] Such as figure 1 with Figure 4 As shown, the present invention also provides a method suitable for on-machine measurement of the outer diameter of an energetic rotating part, including the measuring device described in Embodiment 1, comprising the following steps:

[0047] Step 1: Fix the suction cup 5 on the end face of the machine tool spindle, and use the "self-turning" method to complete the machining of the X0 column section of the outer diameter process reference (generally the cylindricity is less than 0.003mm), and measure the XO value;

[0048] Step 2: complete the machining of the outer cylinder X1 of the workpiece 6 by cutting;

[0049] Step 3: Invoke the whole set of measuring devices on the table frame 1, start the outer diameter measurement program, rotate the spindle at low speed, first measure the outer diameter reference X0 of the suction cup 5 with the horizontal stylus 4.2 (coordinate value, return the dial gauge 2 to zero), and follow the numerical...

Embodiment 3

[0052] Such as figure 2 with Figure 4 As shown, the present invention also provides a method suitable for on-machine measurement of the inner diameter of a blind hole suitable for an energetic rotating part, including the measuring device described in Embodiment 1, comprising the following steps:

[0053] Step 1: Fix the suction cup 5 on the end face of the machine tool spindle, and use the "self-turning" method to complete the machining of the X0 column section of the outer diameter process reference, and measure the XO value (this operation is not required if it already exists);

[0054] Step 2: Complete the machining of workpiece 6 blind hole X2 by cutting;

[0055] Step 3: Invoke the entire set of measuring devices on the table frame 1, start the blind hole inner diameter measurement program, rotate the main shaft at a low speed, first use the vertical probe 4.1 to measure the outer diameter reference X0 of the suction cup 5 (coordinate value, return the dial gauge 2 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com