Drilling Safety Monitoring and Intelligent Protection System

A technology of safety protection and safety monitoring, applied in the automatic control system of drilling, drilling equipment, earth-moving drilling, etc., can solve the problem of not meeting the standards and actual work requirements on site, easy deformation and shearing force of positioning pins, and injury to field workers. and other problems, so as to meet the needs of oilfield exploration and development, ensure the safety of life and property, and improve the effectiveness of drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

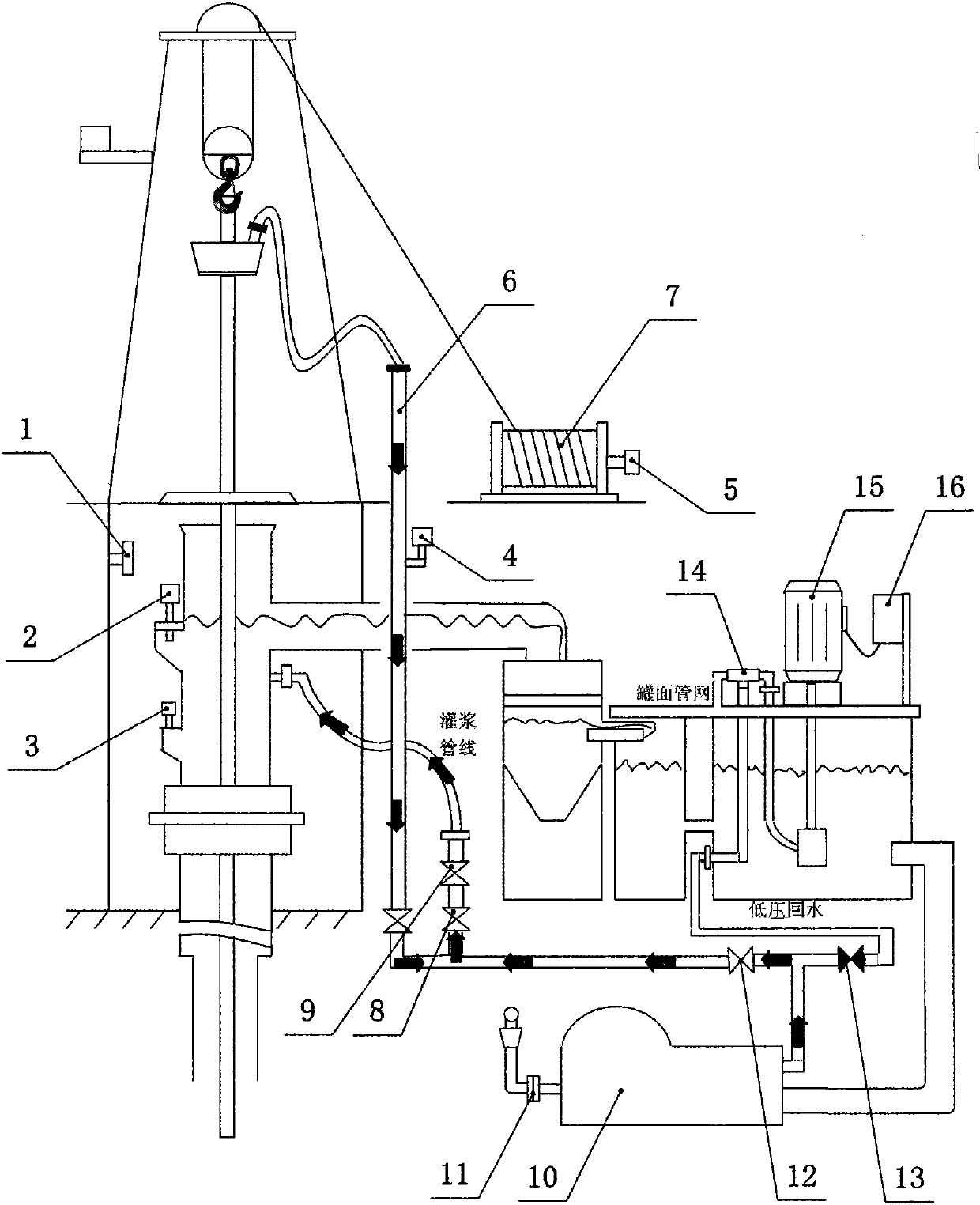

[0085] see figure 1 , figure 2 or image 3 The drilling safety monitoring and protection device of the present invention includes a data acquisition unit, a control processing unit, and a safety protection execution unit. The control processing unit includes a PLC and an industrial computer. The PLC is connected to the industrial computer through a serial port, and each of the data acquisition units After real-time collection of on-site operation data by sensors, the AD module converts it and transmits it to the PLC and the industrial computer. The industrial computer judges whether to take safety protection measures according to the preset program, and starts the safety protection execution unit through the PLC. The safety protection execution unit The unit includes an electronically controlled pump pressure protection mechanism and a multifunctional traveling block protection mechanism, and the configuration of the corresponding data acquisition unit includes: installed in...

Embodiment 2

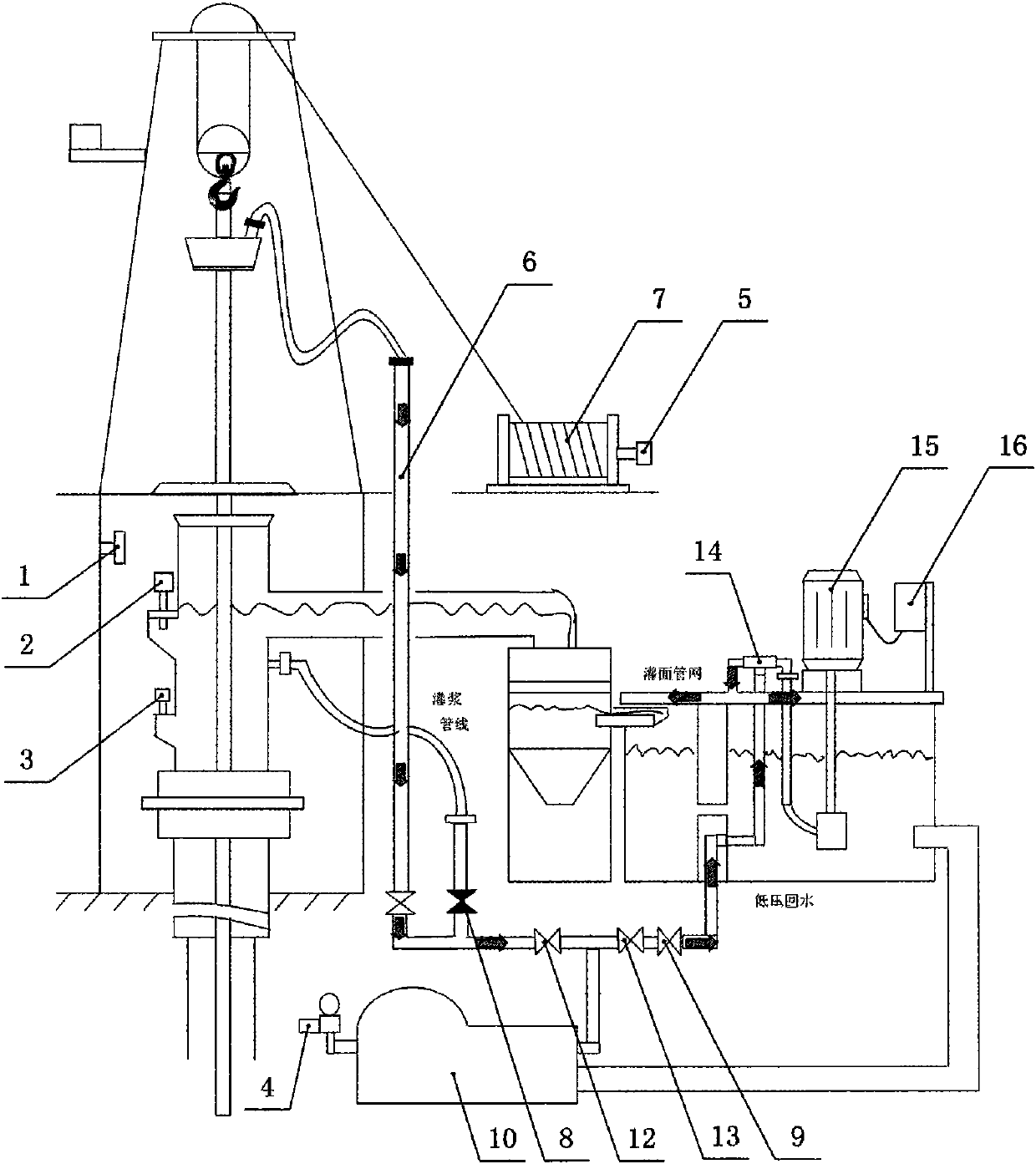

[0088] see figure 1 , figure 2 or image 3 , Figure 4 . The drilling safety monitoring and protection device of this embodiment is different from Embodiment 1 in that the configuration of the electronically controlled pump pressure protection mechanism is as follows:

[0089] 1) Install a normally closed pneumatic valve downstream of the grouting valve or the low pressure return valve of the high pressure pipeline;

[0090] 2) For mechanical drilling pumps, a normally open pump pressure protection solenoid valve 18 is installed on the air circuit between the drilling pump control switches. The pump pressure protection solenoid valve 18 adopts a two-position five-way solenoid valve. The inlet P of the valve 18 is connected to the control air source, and the normally open outlet A of the pump pressure protection solenoid valve is divided into two paths, one path is connected to the inlet gas path of the manual switch valve of the drilling pump, and the other path is connec...

Embodiment 3

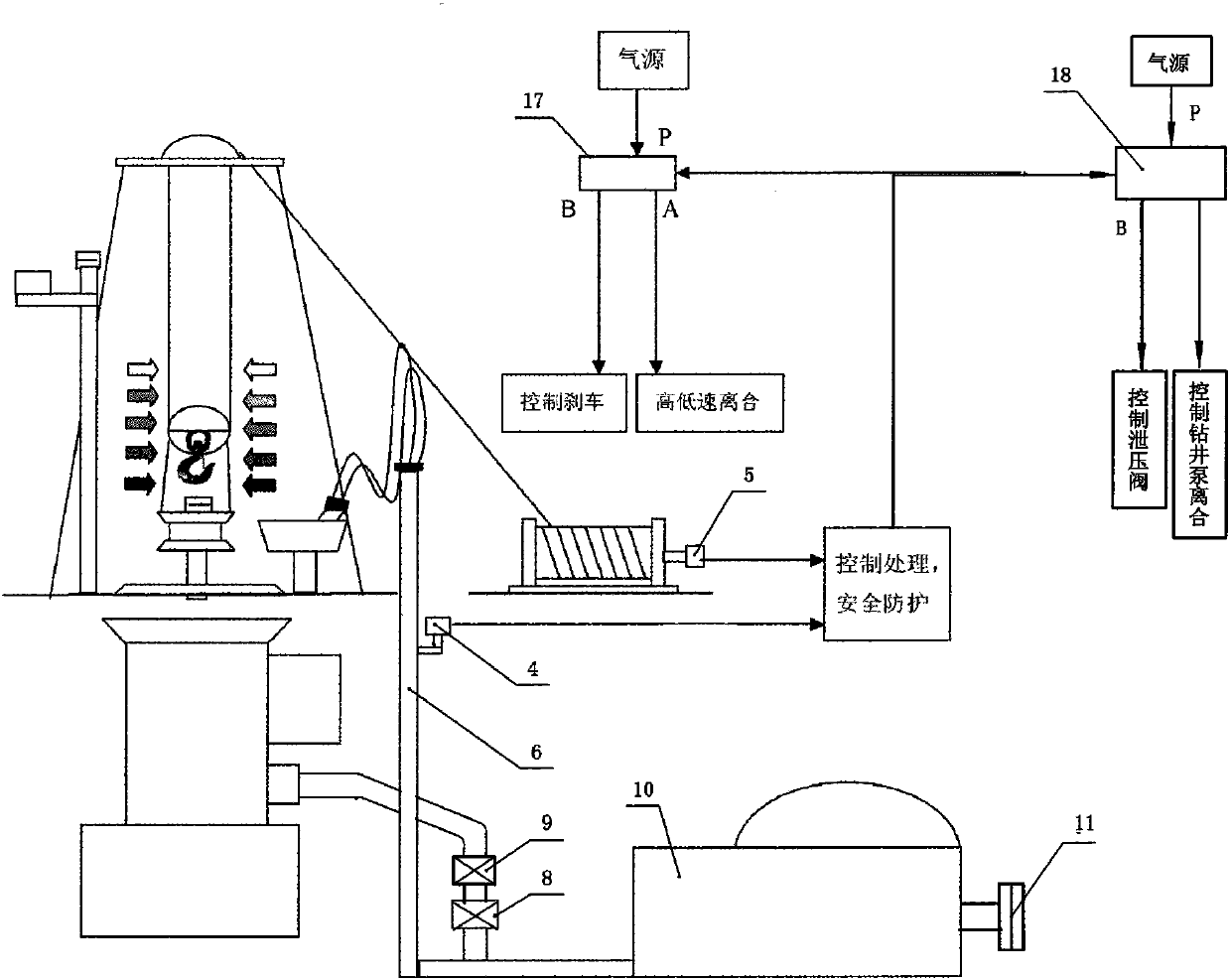

[0096] see figure 1 , figure 2 or image 3 , Figure 5 . The drilling safety monitoring and protection device of this embodiment is different from Embodiment 2 in that the configuration of the electronically controlled pump pressure protection mechanism is as follows:

[0097] For mechanical drilling pumps, a normally open pump pressure protection solenoid valve 18 is installed on the outlet gas path of the manual switch valve of the drilling pump. The pump pressure protection solenoid valve 18 adopts a two-position five-way solenoid valve, and the pump pressure protection solenoid valve The inlet P of 18 is connected with the outlet of the manual on-off valve of the drilling pump, the normally open outlet A of the pump pressure protection solenoid valve 18 is connected with the drilling pump control air circuit, and the normally closed outlet B is blocked; A normally open pressure relief protection solenoid valve 19 is installed between the pressure valve control air cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com