A kind of preparation method of flow pattern regulator for synthetic base drilling fluid and flow pattern regulator

A flow pattern regulator, drilling fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as difficulty in drilling fluid flow, and achieve the effect of meeting development needs and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Under the protection of nitrogen, according to the molar ratio of carboxyl group and amine group of 1:1, add 80 grams of unsaturated dimer fatty acid to the flask, heat to 100 ° C for 15 minutes, weigh 10 grams of diethylenetriamine, and move to constant pressure In the dropping funnel, add amine at 100°C, and the dropping time is controlled at 30 minutes. After the dropping is completed, the temperature is slowly raised to 140°C, stirred at 300rpm for 2 hours, and reacted until the acid value ≤ 5.0 (mg KOH / g); then the intermediate product A was cooled to 100°C, according to the mass ratio of the intermediate product A to the alkoxylated derivative 70:30, then 36.4 grams of polyoxyethylene cocoamine was added, stirred for about 2 hours, and the finished product B was obtained.

Embodiment 2

[0042] Under the protection of nitrogen, according to the molar ratio of carboxyl group and amine group of 1:4, add 74 grams of unsaturated dimer fatty acid into the flask, heat to 100 ° C for 15 minutes, weigh 40 grams of tetraethylenepentamine, move to constant pressure drop In the liquid funnel, the amine addition operation was carried out at 100°C, and the dropping time was controlled at 30min. After the dropping was completed, the temperature was slowly raised to 150°C, and kept stirring at 300rpm for 4 hours, until the acid value ≤ 5.0 (mg KOH / g); then intermediate product A was cooled to 120°C, according to the mass ratio of intermediate product A to alkoxylated derivatives 50:50, then 110 g of polyoxyethylene octadecylamine was added, stirred for about 4 hours, and finished product C was obtained.

Embodiment 3

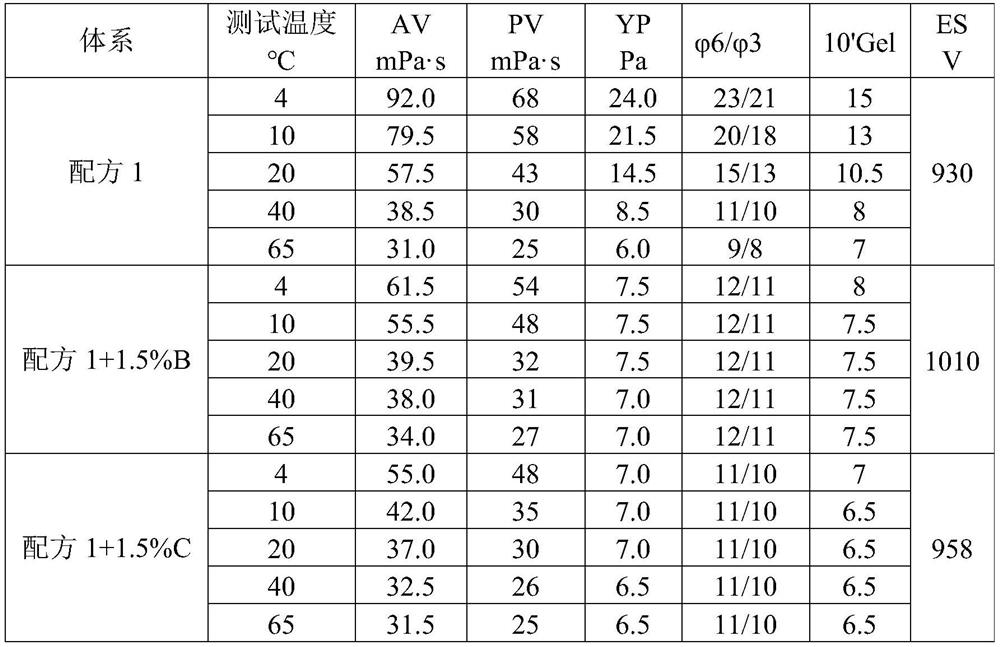

[0044] Add the flow regulator prepared by the present invention in the synthetic base drilling fluid system and evaluate the rheological change of the sample under different temperature conditions without adding:

[0045] Synthetic-based drilling fluid formula 1: Add 8g of primary emulsifier SMEMUL-1, 6g of secondary emulsifier SMEMUL-2, 80mL of 25% calcium chloride aqueous solution, 8g of organic soil, 8g of fluid loss reducer, each treatment agent needs to be stirred at high speed for 10 minutes, and finally 700 barite is added, stirred at high speed for 20 minutes, and the density is 2.0g / cm 3 traditional synthetic-based drilling fluid system. At the same time, 3 groups of the same formula were prepared, and 6 g of flow regulators B and C were added to the other two groups of systems. Among them, the main emulsifier SMEMUL-1 and the auxiliary emulsifier SMEMUL-2 are self-developed products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com