Mold provided with mechanism for directly pushing out slider insert through ejector retainer plate

A needle plate and slider technology, which is applied in the field of molding molds for plastic products, can solve the problems of low precision and difficulty in installing precision inserts, meet the requirements of ensuring sliding stability and precision, reduce product defect rates, and facilitate installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

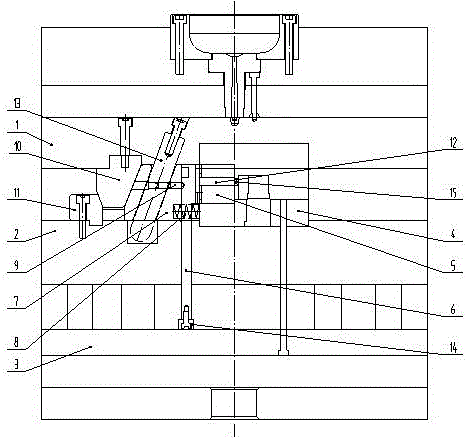

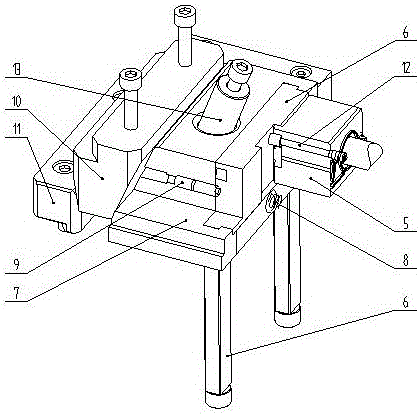

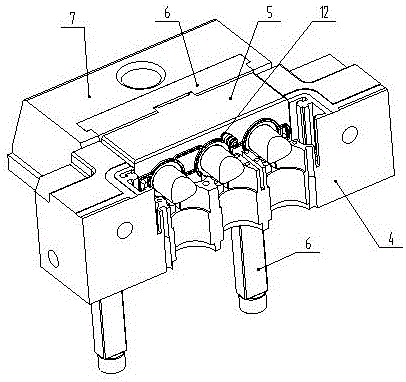

[0018] Specific embodiments of the invention will be described in detail below in conjunction with technical text and accompanying drawings.

[0019] When assembling the mould, install the oblique guide post 13 in the counterbore processed by the fixed template 1 to lock and fix it, and install the inclined wedge 10 in the processed cavity of the fixed template 1. Template 1 locks it in place (see figure 1 ), the movable mold insert 4 is installed in the cavity processed by the movable template 2, the bolt passes through the fixed template 2 to lock and fix it, and the slider core 12 is installed in the through hole processed by the slider main body 5 to hang The platform limit, the slider core 12 and the slider main body 5 are assembled with the slider insert 6 as a whole and positioned by the boss, the bolt passes through the slider core 12 to lock and fix it with the slider main body 5, and the ball head tops The wire 9 is screwed into the thread hole processed by the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com