A hard carrier thermal printer

A thermal printer and carrier technology, applied in the printing field, can solve the problems of easy damage to the print head and ribbon, reduced life of the print head, non-printing consumption of the ribbon, etc., to simplify the structural design, increase the service life, and avoid rigid collisions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

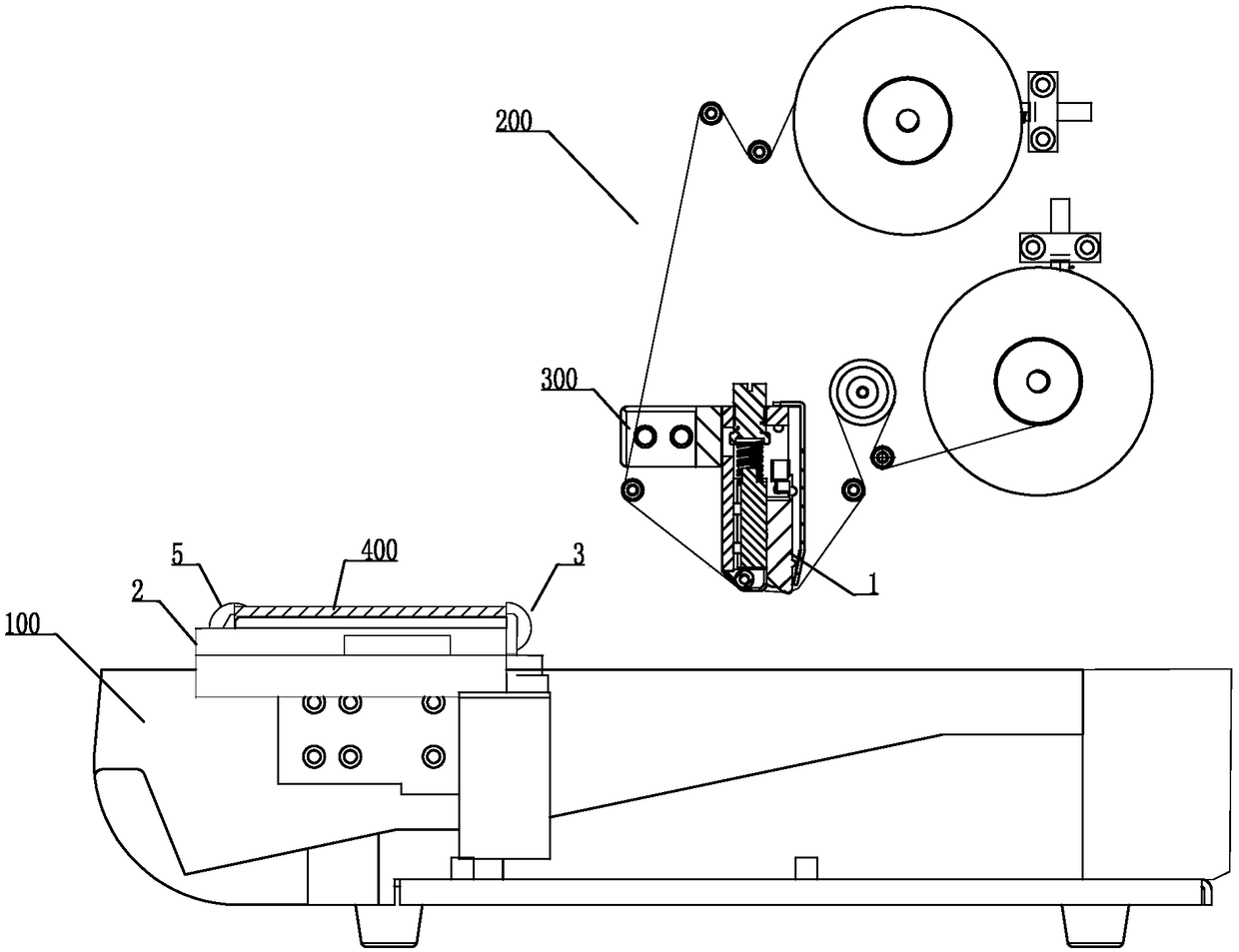

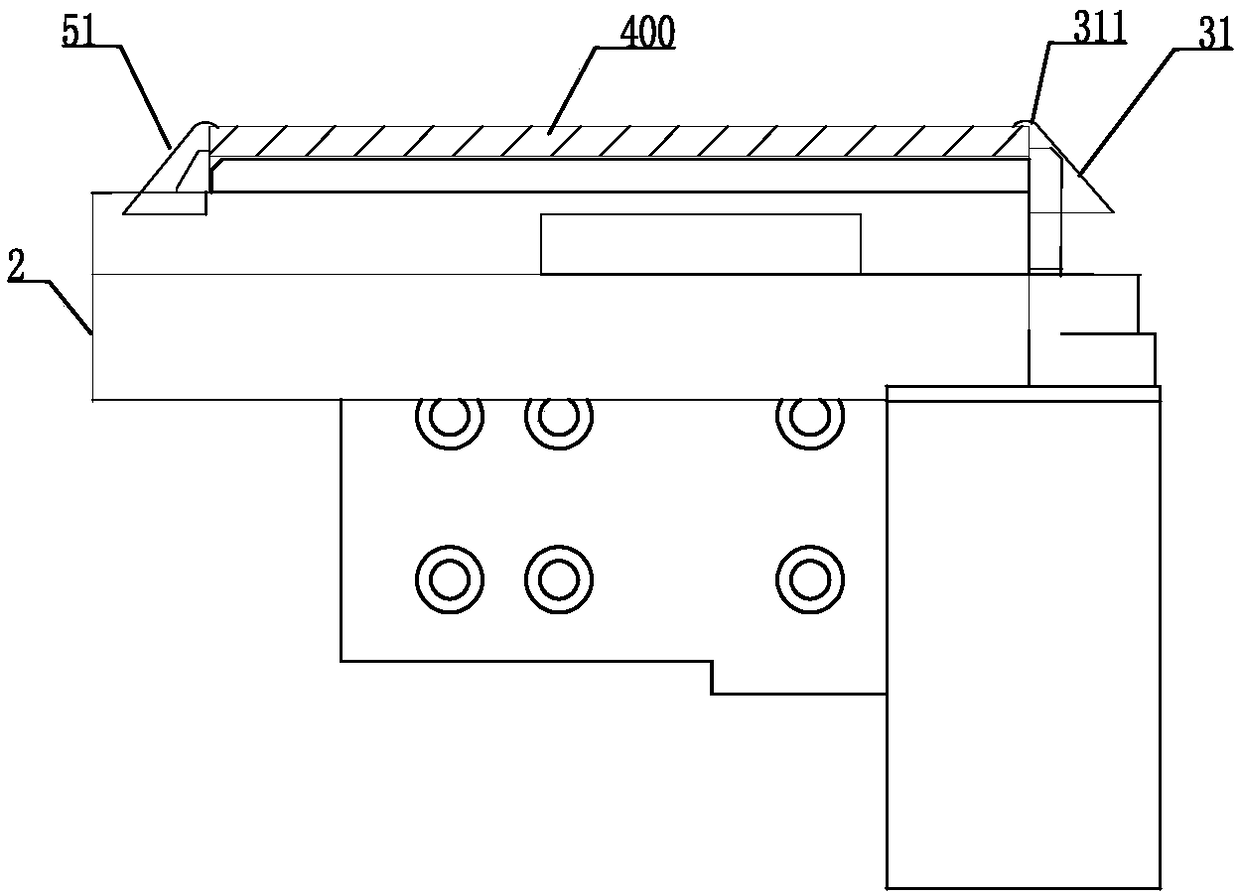

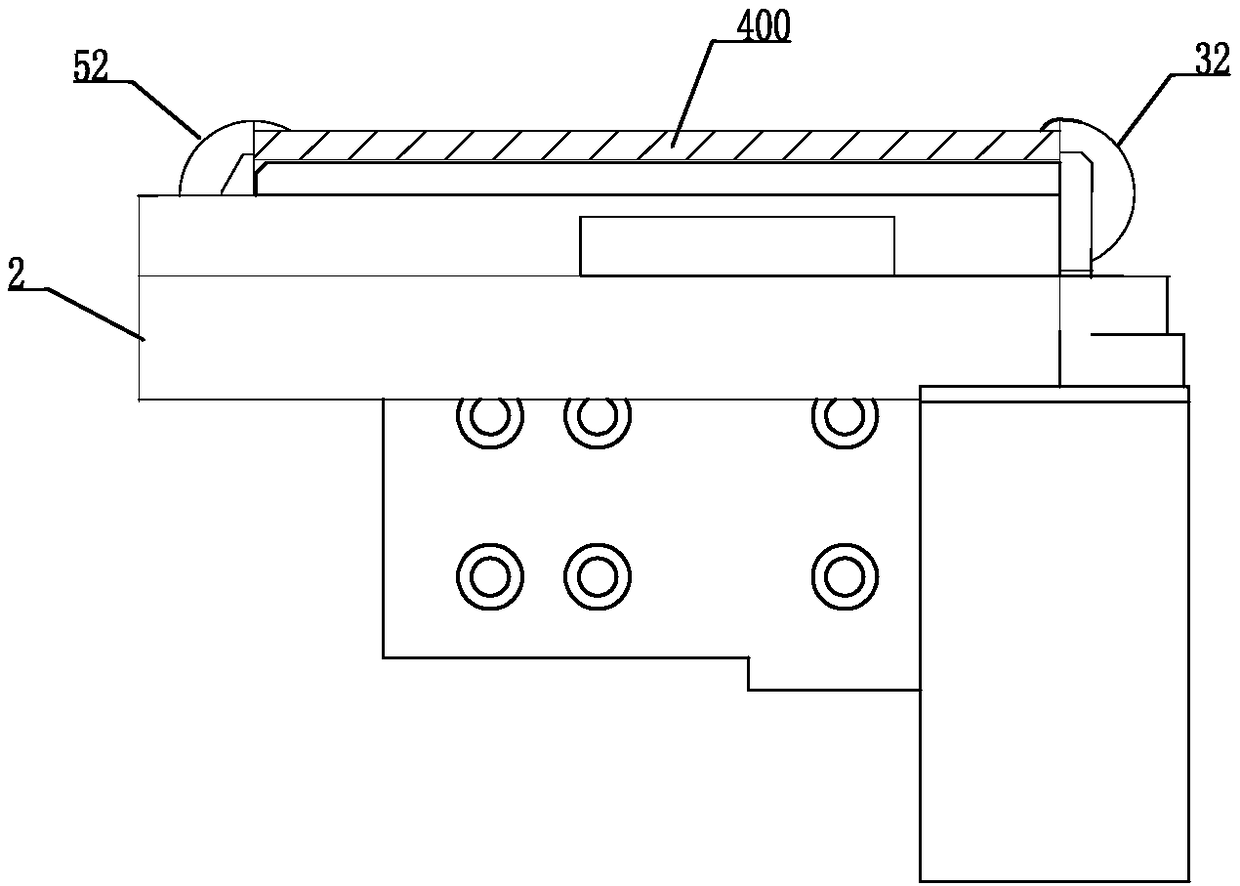

[0028] Such as figure 1 The hard carrier thermal printer shown includes a print head 1 , a ribbon module 200 , a mobile base 2 and an installation base 100 .

[0029] Among them, the print head 1 prints the information on the hard carrier by means of thermal transfer barcode, the print head 1 is facing downward, and the bottom end of the print head 1 can be pushed upward by an external force to make a small upward displacement, and in the After the external force is withdrawn, it will move downward again and return to the original position. The above-mentioned hard carrier can be ceramic, glass or plastic box.

[0030] The carbon ribbon module 200 includes a series of conveying rollers and a carbon ribbon for printing. The carbon ribbon is a rotary structure, and a part of it is always pressed against the bottom of the print head 1 , so that it can always be distributed to the print head 1 .

[0031] The installation base 100 is located under the print head 1 and is fixed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com