A kind of mine mortar conveying pipeline

A technology for conveying pipelines and mortar, which is applied in the field of mining mortar transportation equipment, and achieves the effects of simple device and structure, automatic control, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

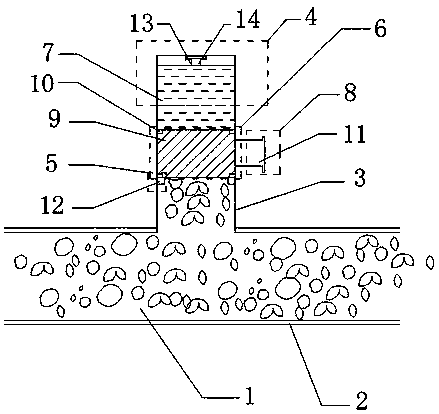

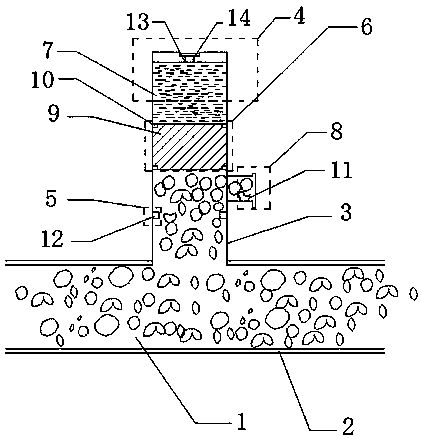

[0022] Such as figure 1 and figure 2 As shown, a mine mortar delivery pipeline includes a delivery pipeline 1, the inner wall of the delivery pipeline 1 is provided with a scour-resistant layer 2, and the delivery pipeline 1 is provided with a floating pressure divider 3 of a hollow structure, and the floating pressure divider 3 and The delivery pipeline 1 is fixedly sealed and connected to each other, and the end of the floating pressure divider 3 away from the delivery pipeline 1 is a closed end 4, inside the floating pressure divider 3, along the radial direction of the delivery pipeline 1, from near to far A blocking part 5, a floating sealing part 6 and a hydraulic oil part 7 are provided, and a discharge part 8 is provided under the floating sealing part 6. It is used to seal the hydraulic oil in the hydraulic oil part 7 and can slide in the floating pressure divider 3 , and the discharge part 8 is used to divert the mortar in the conveying pipeline 1 .

[0023] exist...

Embodiment 2

[0036] Embodiment 2 is the same as Embodiment 1, except that the polyurethane composite material is composed of the following raw materials in parts by weight: 96 parts of polyurethane prepolymer, 3 parts of polyurethane toughening agent, and 6 parts of modified rare earth oxide powder , 4 parts of superfine vanadium oxide powder, 9 parts of carbon fiber, 3 parts of silane coupling agent, 37 parts of curing agent, 2 parts of defoamer, 170 parts of silica particles, 2 parts of rare earth dithiocarbamate accelerator and Anti-aging agent 4 parts. Among them, the silica particles are composed of a mixture of two specifications with a particle size of 0.1-0.3mm and a particle size of 0.5-0.7mm. The mass ratio of silicon oxide particles to 0.5-0.7mm (the particle size is not specifically limited, but within 0.5-0.7mm) particle size silicon dioxide particles is 1:2; the anti-aging agent is lanthanum p-aminobenzenesulfonate anti-aging agent , the toughening agent is polyurethane, the...

Embodiment 3

[0047] Embodiment 3 is the same as Embodiment 1 and Embodiment 2, except that the polyurethane composite material is composed of the following raw materials in parts by weight: 90 parts of polyurethane prepolymer, 2 parts of polyurethane toughening agent, modified rare earth oxidation 5 parts of powder, 3 parts of superfine vanadium oxide powder, 8 parts of carbon fiber, 1 part of silane coupling agent, 30 parts of curing agent, 1 part of defoamer, 150 parts of silica particles, rare earth dithiocarbamate accelerator 1 part of anti-aging agent and 1 part of anti-aging agent. Among them, the silica particles are composed of a mixture of two specifications with a particle size of 0.1-0.3mm and a particle size of 0.5-0.7mm. The mass ratio of silicon oxide particles to 0.5-0.7mm (the particle size is not specifically limited, but within 0.5-0.7mm) particle size silicon dioxide particles is 1:2; the anti-aging agent is lanthanum p-aminobenzenesulfonate anti-aging agent , the tough...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com