Device for preventing fasteners from being twisted during installation of elastic bars

A technology of fasteners and elastic strips, applied in the field of rail transit, to simplify the adjustment process of fastener spacing, convenience and accuracy, and improve overall stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

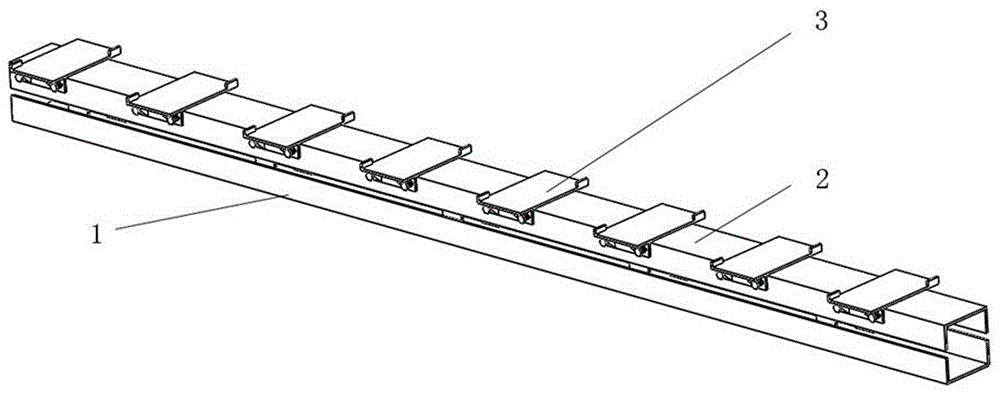

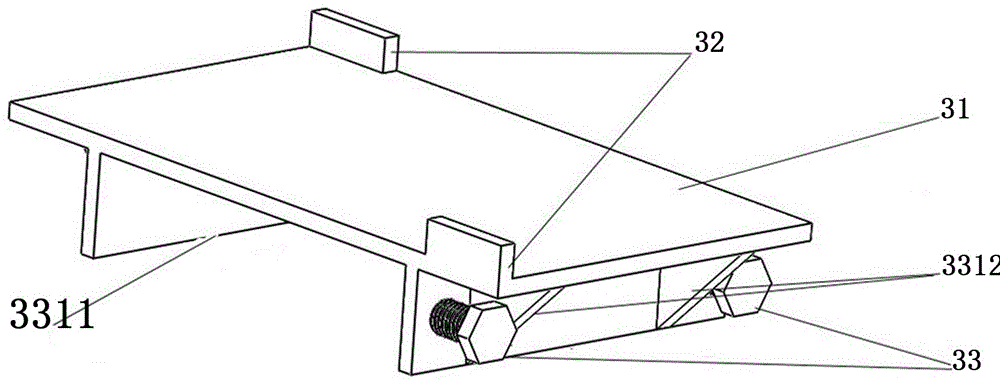

[0028] Such as figure 1 , figure 2 , image 3 As shown, the device body 1 includes a support base 2 and a plurality of bearing grooves 3 for fixing the fastener bottom plate 4. The support base 2 is a large-mass structure parallel to the rail of the fastener clip to be installed. The length of the base 2 is not less than the length of the fastener rail to be installed; the plurality of bearing grooves 3 are fixedly arranged on the supporting base 2; the bearing grooves 3 are provided with a bearing plate 31, a shoulder 32 and a connecting mechanism 33, There are at least two shoulders 32, which are respectively arranged on both sides of the top of the bearing plate 31. The width of the inner cavity formed by the shoulders 32 is equal to the width of the fastener bottom plate 4. The bearing groove 3 passes through the connecting mechanism 33. Fixedly connected with the support base 2, the bearing plate 31 has the same shape and size as the fastener base plate 4, and the sho...

Embodiment 2

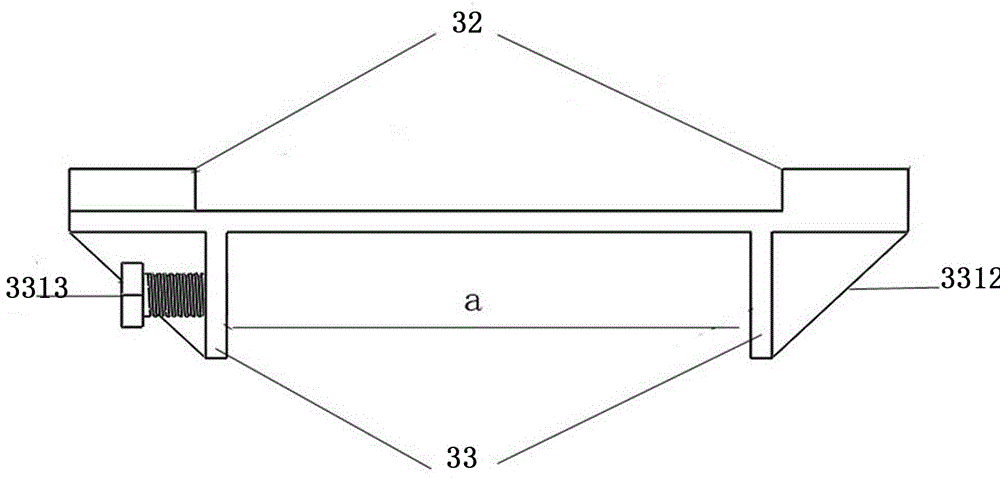

[0032] Figure 6 , Figure 7A schematic structural view of Embodiment 2 of the present invention is given. The main structure of this embodiment is the same as that of Embodiment 1. In this embodiment, the supporting base 2 of the device body 1 is a steel rail with a large mass, and the bearing groove 3 There are two symmetrical shoulders 32, and the connection mechanism 33 between the bottom of the carrying tank 3 and the support base 2 is designed according to the shape of the rail, and is composed of a fixed baffle 3321, a locking mechanism 3322 and a tightening screw 3323. There are at least two baffles 3321, both of which are arranged on the bottom of the bearing plate 31, and are clamped and fixed on the top of the support base 2. The locking mechanism 3322 is clamped at the middle of the support base 2, and is tightened by a screw rod 3323 Fixed and locked; when in use, put the bearing groove 3 from the end of the rail on one side and place it on the support base 2, se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com