A cone-mill integrated drill bit for ground stress testing

An integrated, in-situ stress technology, used in drill bits, earthwork drilling, drilling equipment, etc., can solve the problems of time wasting, time-consuming and laborious, and difficulty in judging drilling rig footage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

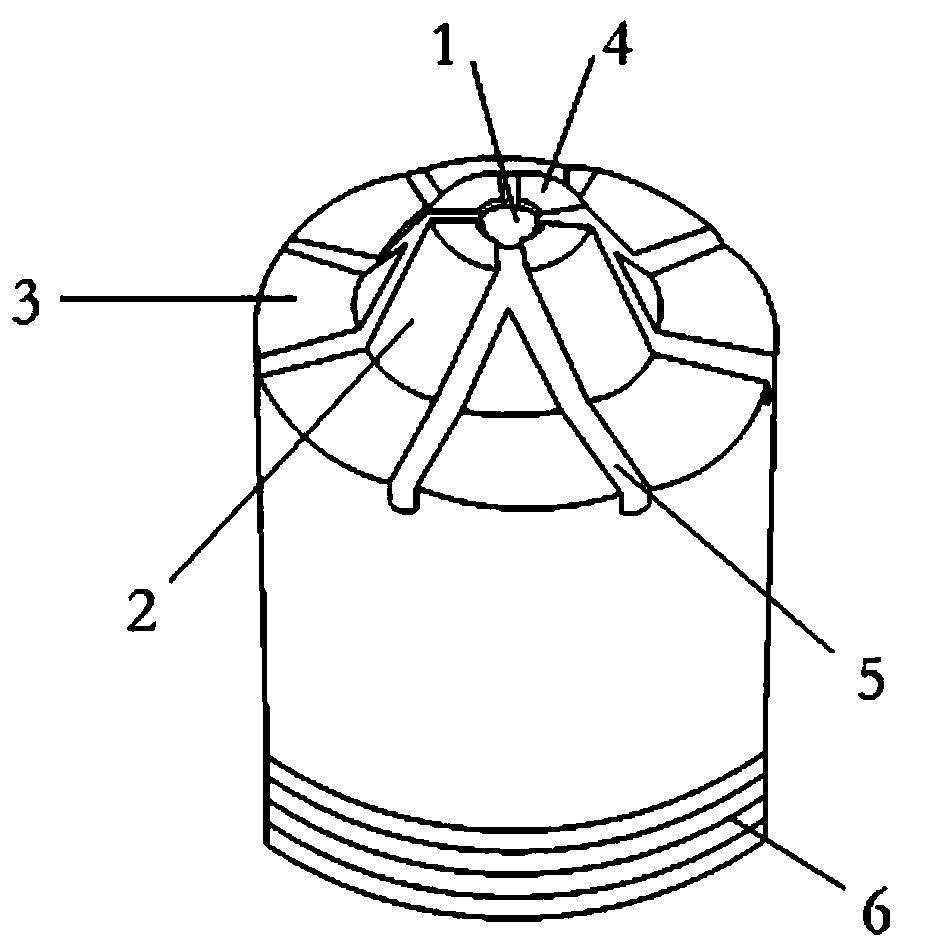

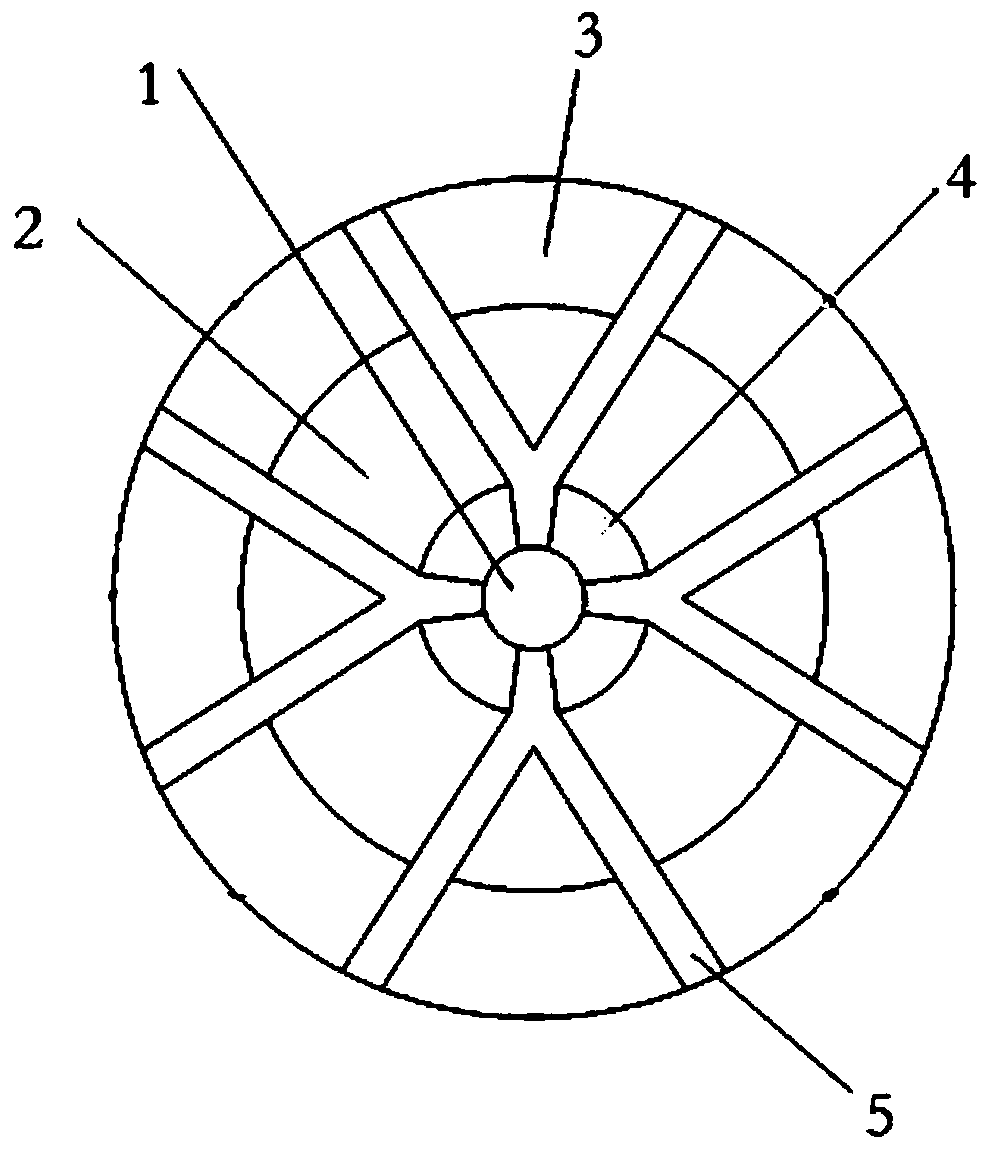

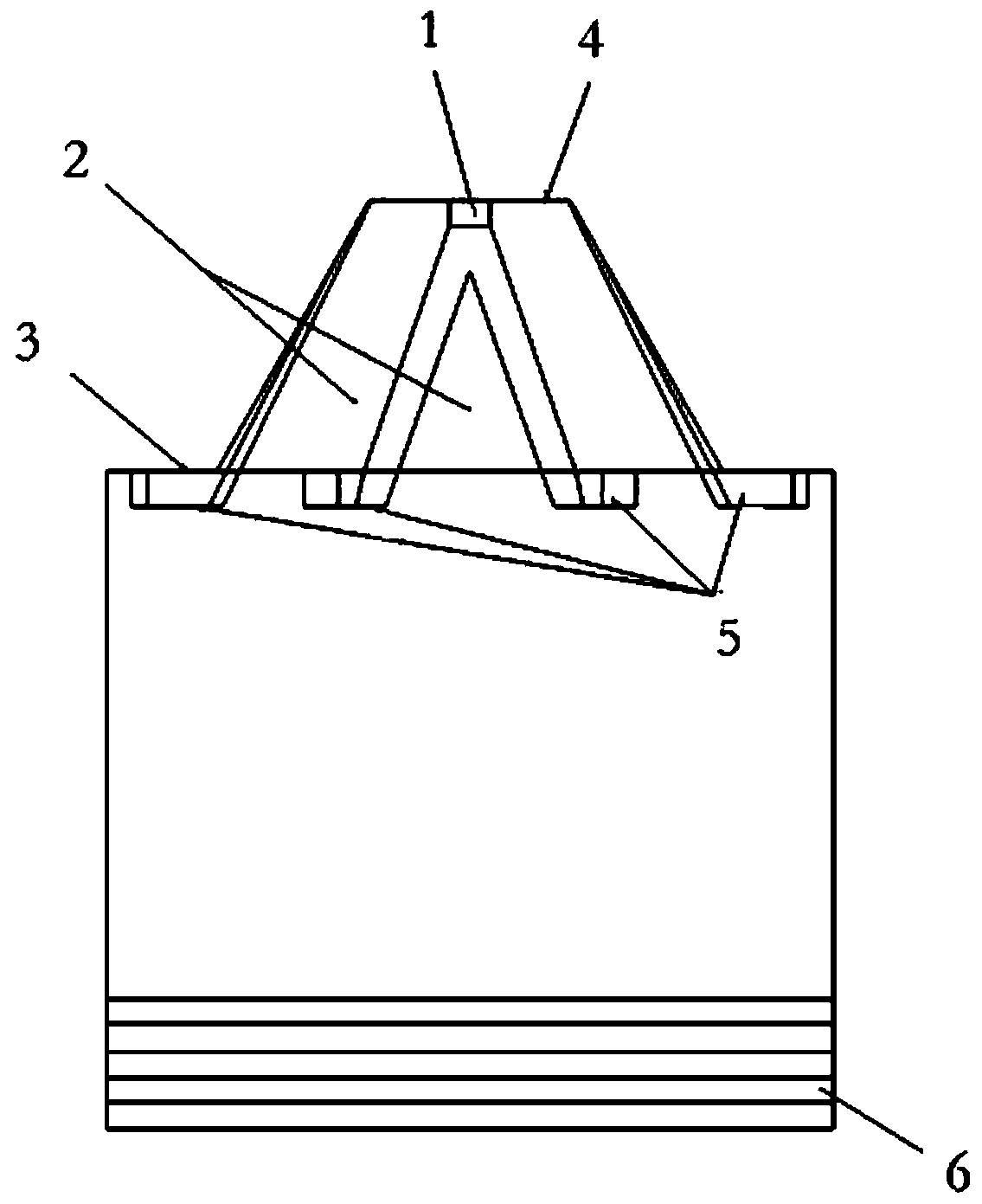

[0027] Such as Figure 1~3 As shown, a cone-grinding integrated drill used for ground stress testing includes a water return port 1. The outer side of the water return port 1 is a cone plane 4, the outer edge of the cone plane 4 is connected to the cone surface 2, and the other end of the cone surface 2 is connected to The grinding plane 3 is connected, the grinding plane 3 is parallel to the cone plane 4, and the drainage channel 5 is connected with the water return port 1 through the grinding plane 3, the cone surface 2 and the cone plane 4. There are four drainage channels 5 in the shape of "people", and their bifurcation points are located at the junction of the cone plane 4 and the cone plane 2. The tapered surface 2, the grinding surface 3 and the tapered surface 4 are made of electroplated diamond, and the angle between the tapered surface 2 and the horizontal surface is 60 degrees. A threaded button 6 is processed on the outer wall of the end of the drill bit.

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com