A valve actuator based on gas-hydraulic combined spring

A technology of valve actuator and combined spring, which is applied in the direction of valve details, valve device, valve operation/release device, etc., can solve the problems of easy fatigue failure, troublesome installation, heavy quality, etc., and achieve safety, reliability, convenient installation, Safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

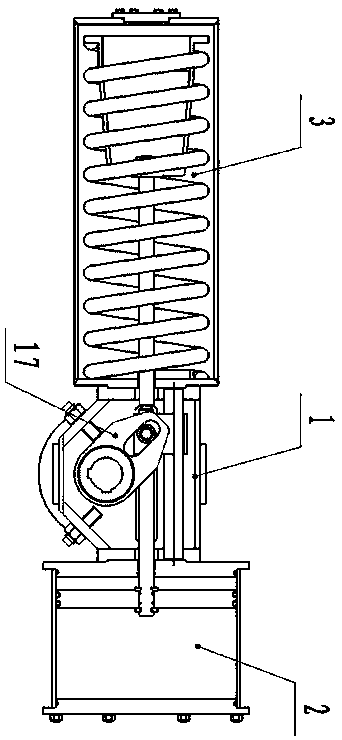

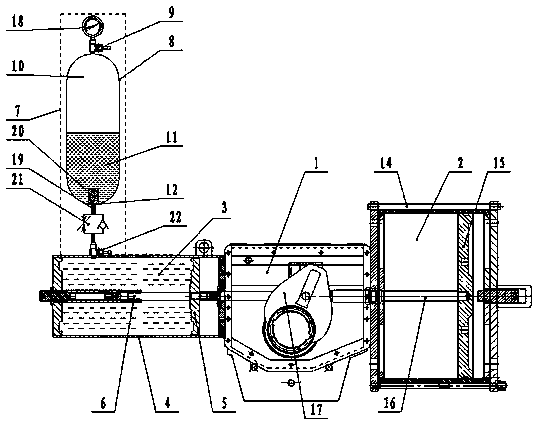

[0042] Such as figure 2As shown, a valve actuator based on a gas-hydraulic combined spring includes an actuator 1 and a power cylinder 2. The power cylinder 2 adopts a pneumatic cylinder, and the pneumatic cylinder is installed on the side of the actuator 1. The installation of the pneumatic cylinder and the actuator 1 The connection mode is the same as that of the prior art, and the structure of the actuator 1 also adopts the existing structure. The other side of the actuator 1 is provided with a gas-hydraulic combination spring cylinder 3, which includes a spring cylinder body 4 and a spring piston 5. And the spring piston rod 6, the spring piston rod 6 is arranged in the spring cylinder 4, the spring piston 5 is fixedly arranged on the spring piston rod 6, the spring cylinder 4 is provided with a gas-liquid combination spring device 7, and the gas-liquid combination spring device 7 Including a pressure vessel tank 8, the upper end of the pressure vessel tank 8 is provided ...

Embodiment 2

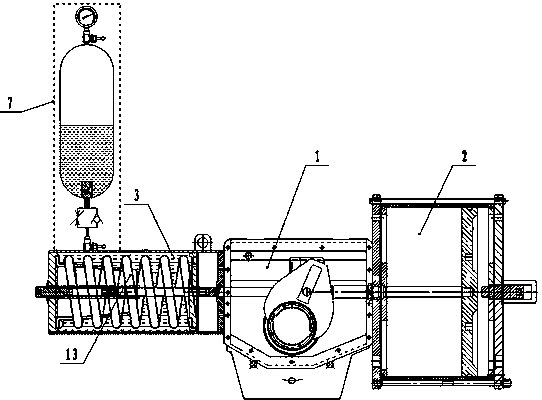

[0058] Such as image 3 As shown, a valve actuator based on a combined gas-hydraulic spring, based on Embodiment 1, a spring 13 is provided on the spring piston rod 6 at the rear end of the spring piston 5 . When the pneumatic cylinder takes in air, the piston 15 of the pneumatic cylinder pushes the piston rod 16 to move forward, and the piston rod 16 pushes the shift fork 17 to open the valve. At the same time, the gas-liquid combined spring device 7 and spring 13 are compressed. The piston 15 pulls the piston rod 16 to retract under the joint action of the gas-hydraulic combination spring device 7, the spring 13 and the pneumatic cylinder, and the piston rod 16 drives the shift fork 17 to reversely move to close the valve.

[0059] On the basis of the original spring cylinder, the front end of the spring in the spring cylinder is provided with a spring piston linked with the spring piston rod. "Device" can greatly reduce the installation size of the original spring cylinder...

Embodiment 3

[0061] Such as Figure 4 As shown, a valve actuator based on a gas-hydraulic combined spring. On the basis of Embodiment 1, the power cylinder 2 adopts a hydraulic cylinder. When the hydraulic cylinder enters oil, the piston 15 of the hydraulic cylinder pushes the piston rod 16 to move forward, and the piston The rod 16 pushes the shift fork 17 to open the valve. At the same time, the gas-hydraulic combination spring device 7 and the spring 13 are compressed. The piston rod 16 retracts, and the piston rod 16 drives the shift fork 17 to reversely move to close the valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com