Non-contact energy-gathered igniter

A detonating device and non-contact technology, applied in blasting and other directions, can solve the problems of high blast sensitivity, poor reliability and safety, and low efficiency, and achieve the effects of increasing power frequency resistance, improving safety, and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

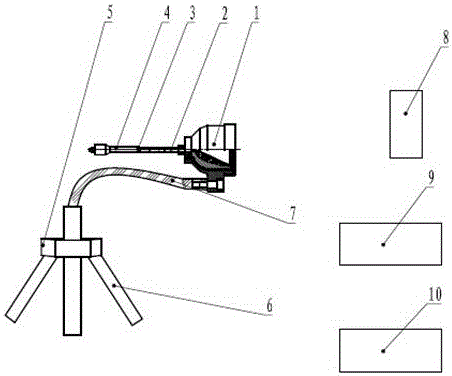

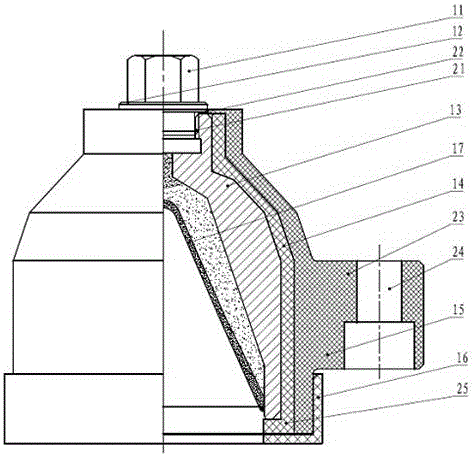

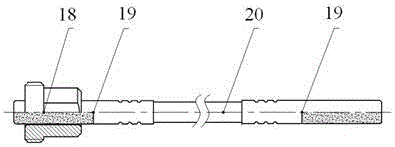

[0028] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0029] refer to Figure 1-3 , a non-contact shaped charge detonating device described in this specific embodiment, comprising a shaped charge warhead 1, a detonation transfer assembly 2, and a magnetoelectric detonator 4 connected in sequence, and the shaped charge warhead 1 includes a shaped charge warhead The energy shell shell 13, the rubber sleeve 14, the warhead shell 15, the end cover 16 and the drug-type cover 17, the energy-shaping shell 13 are placed in the warhead shell 15, and the rubber sleeve 14 is located between the energy-shaping shell 13 and the warhead shell 15. Between, the end cap 16 is installed on the mouth of the warhead shell 15, and the drug-shaped cover 17 is placed in the shaped-energy shell 13, and there is a sealed gap between the drug-shaped cover 17 and the shaped-energy shell 13, and in the gap Packed with dynamite.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com