Rapid-firing projectile launcher

a projectile launcher and rapid technology, applied in the field of toys, can solve the problems of slow actual launching, unreliable and expensive indexing arrangements, and unusable mechanisms, and achieve the effects of improving the accuracy of projectile firing, simple and reliable, and enhancing aiming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

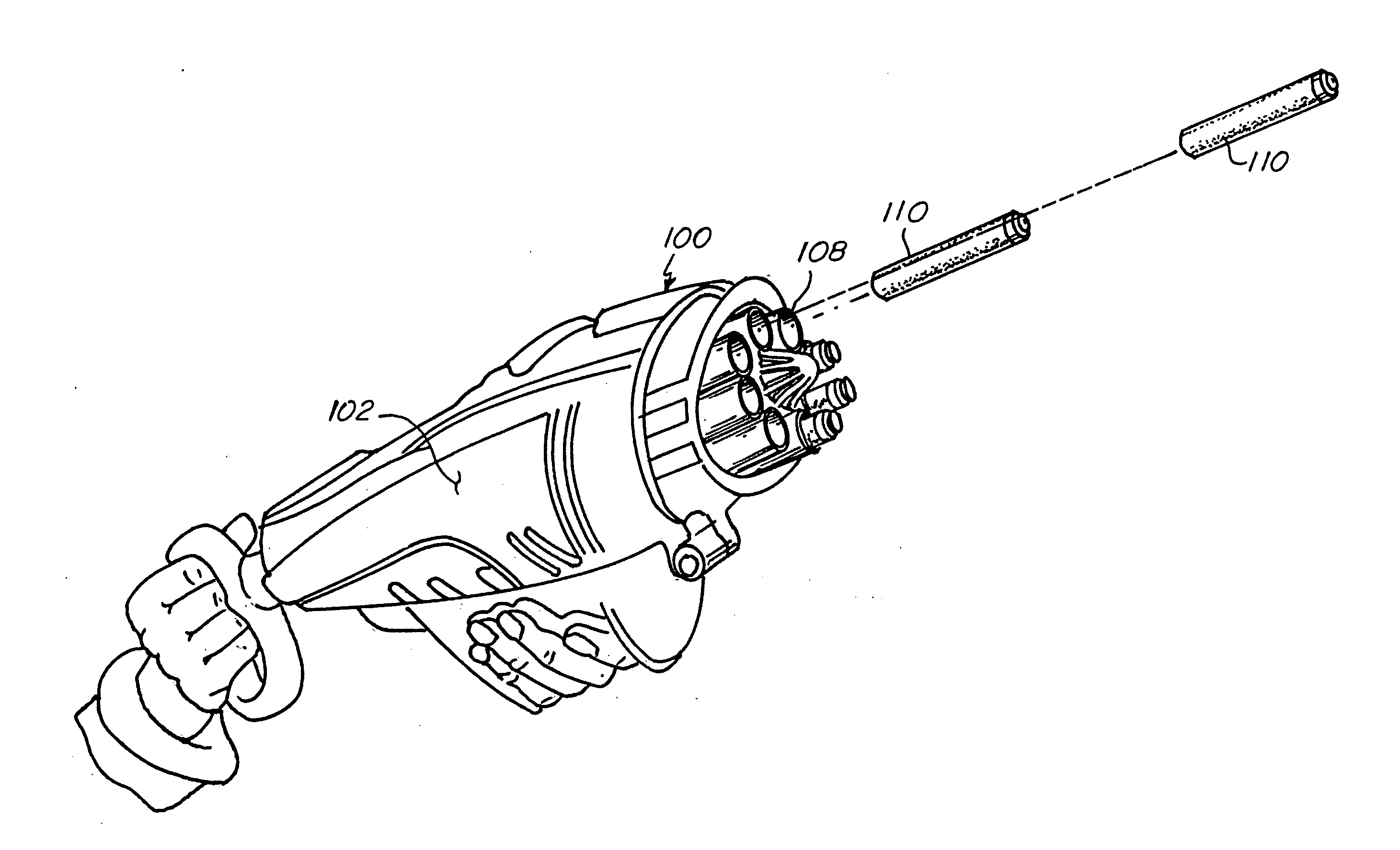

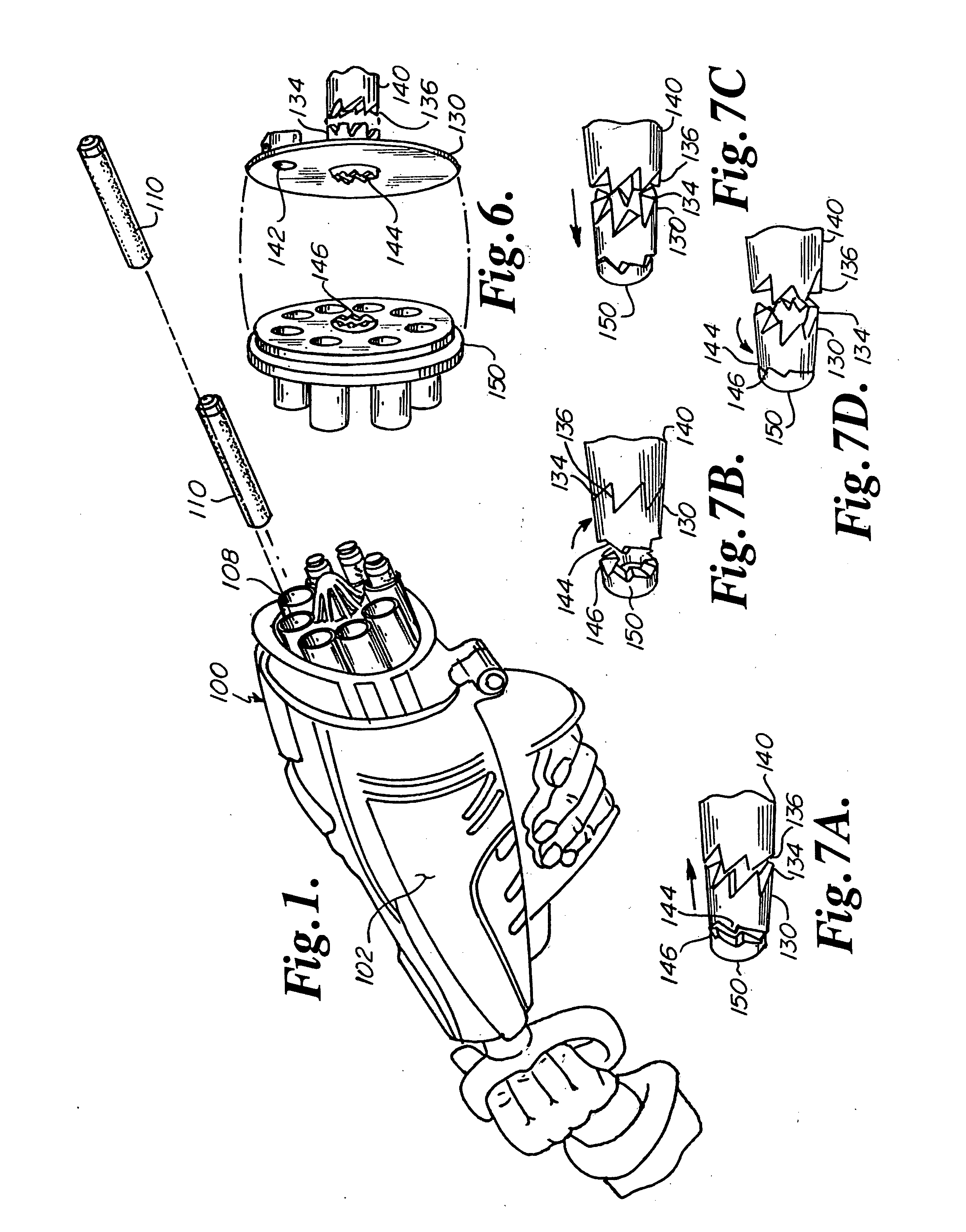

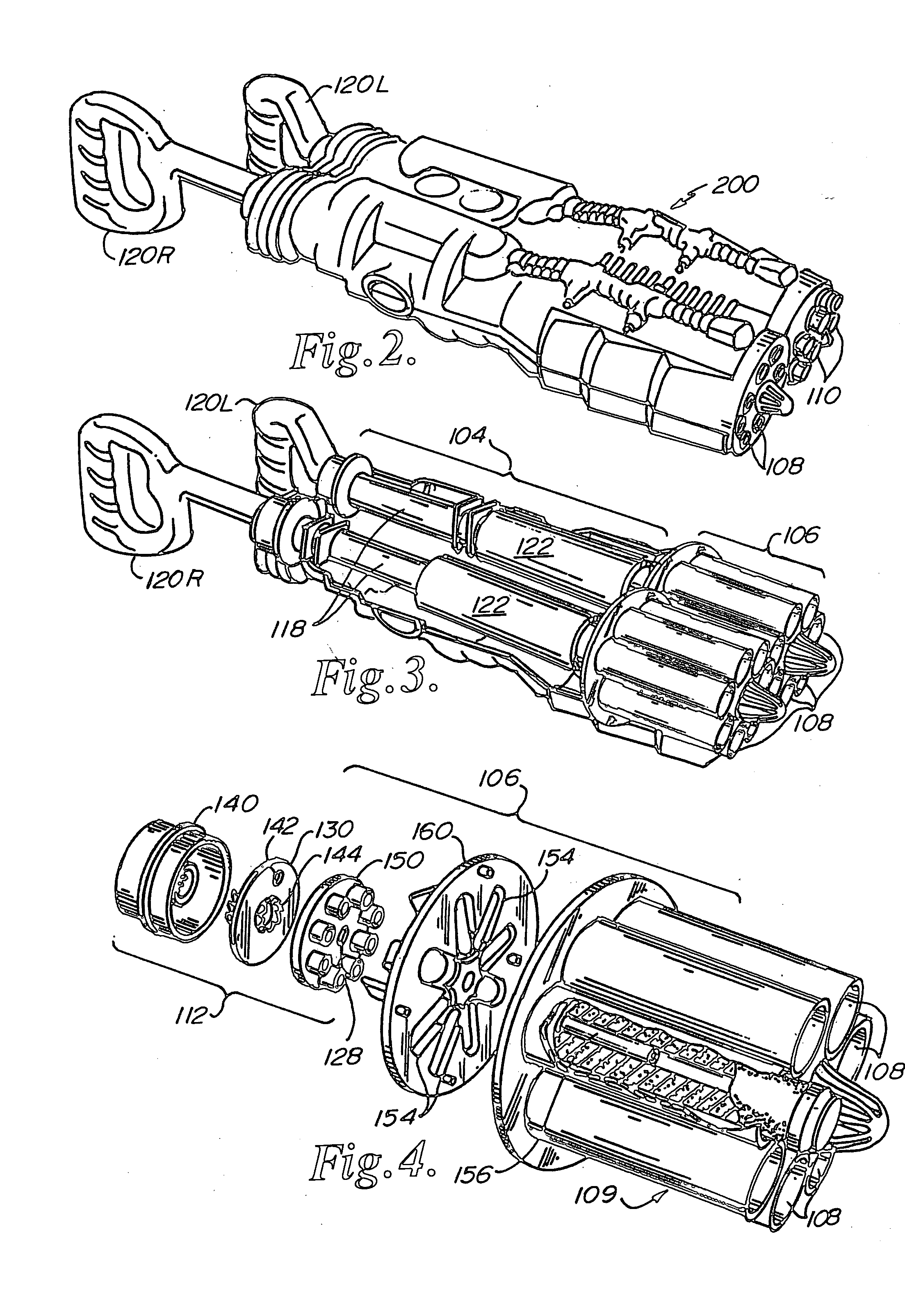

[0018] Referring now to the drawings, two embodiments of the projectile launcher according to the present invention is illustrated in FIGS. 1-8. The launcher 100 of the preferred embodiment is shown in FIG. 1. It comprises a body 102, a piston and cylinder assembly 104, and a launching mechanism 106.

[0019] Launching mechanism 106 has eight equally-spaced launching chambers 108 within magazine 109 for receiving eight projectiles 110, and a manifold assembly 112 for directing air from the piston and cylinder assembly 104 to the launching chambers 108, one at a time and in sequential order upon each successive extension / compression cycle of the piston 118.

[0020] The piston 118 includes a handle 120 at its distal end. The piston is adapted to be moved longitudinally within the cylinder 122 from an extended state (as depicted by the extended position of right-side handle 120R of FIGS. 2 & 3) to a compressed state (as depicted by compressed position of the left-side handle 120L of FIGS....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com