Multi-environment fatigue property testing device for cloth used for conveyor belt

A kind of fatigue performance testing, conveyor belt technology, applied in measuring devices, using stable tension/pressure to test material strength, strength characteristics, etc., can solve the problem of limited test effect, can not meet the needs of use, can not simulate different working environments of fabrics and other problems to achieve accurate test results and meet the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below with reference to the accompanying drawings and in conjunction with the embodiments.

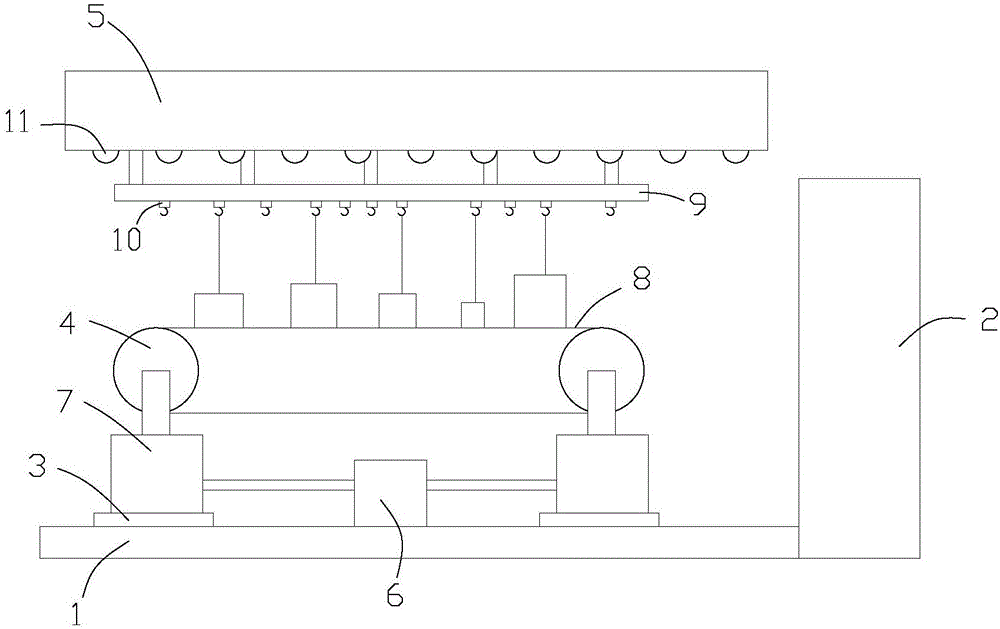

[0012] refer to figure 1 , The multi-environmental fatigue performance test device of a conveyor belt fabric of the present invention is mainly composed of a sliding track 1, a control box 2, a sliding plate 3, a rotating roller 4, and an environmental conversion box 5. The control box 2 is arranged beside the sliding track 1, and is used for the work of each part of the control device. The sliding track 1 is a linear structure, and the number of sliding plates 3 is two, which are respectively arranged on both sides of the sliding track 1 . As shown in the figure, an adjusting motor 6 is arranged between the two sliding boards 3, and the adjusting motor 6 can drive the two sliding boards 3 to move on the sliding rail 1 to change the distance between them. The rotating roller 4 is arranged on the sliding plate 3, and the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com