Fragile material tension and torsion test method and test auxiliary device

A technology of brittle materials and auxiliary devices, which is applied in the direction of measuring devices, analyzing materials, and testing the strength of materials by applying a stable torsion force. Achieve the effects of avoiding breakage, simple and easy process, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A brittle material tension and torsion test method and test auxiliary device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

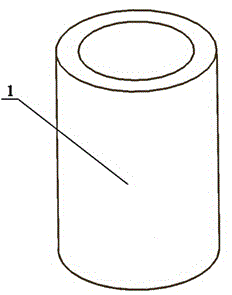

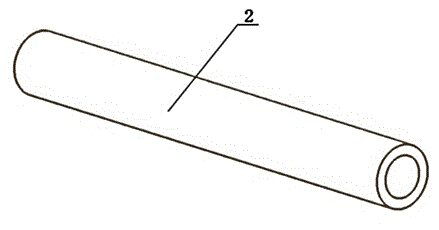

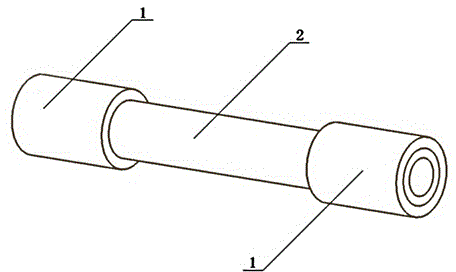

[0031] like Figure 5 As shown, the auxiliary device for tensile and torsion testing of brittle materials of the present invention includes a clamping protective sheath 1 and a protective sheath centering device. like figure 1 and figure 2 As shown, the clamping protective sleeve 1 is a cylindrical sleeve, the inner diameter of which is slightly larger than the outer diameter of the thin-walled round tube tensile and torsion sample 2 . like Figure 4 As shown, the protective cover centering device includes a support frame 3, an upper centering block 4, a threaded rod 5 and a handle 6; the support frame 3 has a base and a column standing on the base. The upper centering block 4 is provided with a threaded hole passing through the upper centering block 4 , and the threaded rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com