A mobile battery string detection device

A detection device and mobile technology, applied in the direction of measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of low detection efficiency, unstable reliability, etc., and achieve easy disassembly, simple structure, and low processing and manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

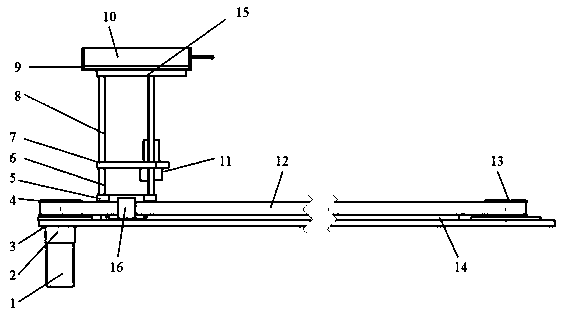

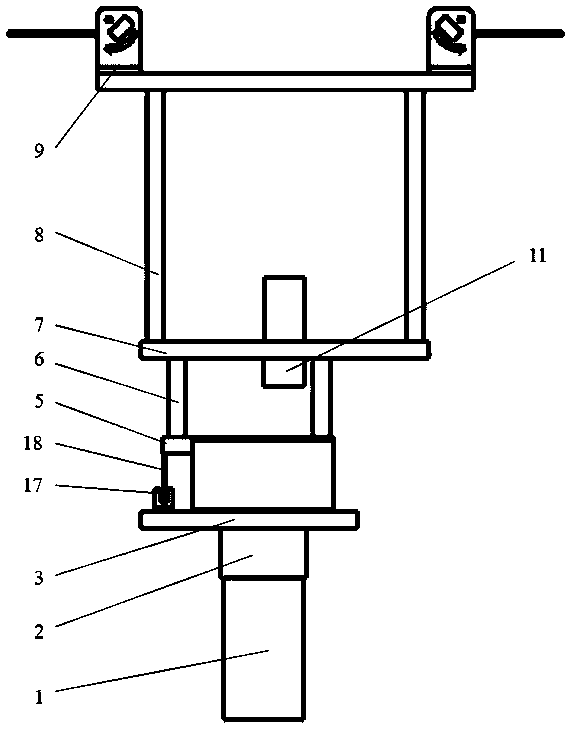

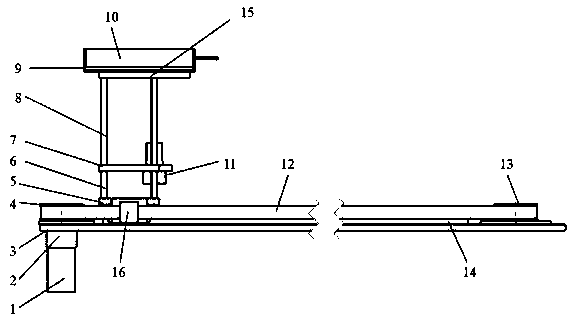

[0016] The embodiments of the present invention are described in detail below, and examples of the embodiments are shown in the accompanying drawings. The embodiments described below with reference to the accompanying drawings are schematic and are intended to explain the present invention, but not to explain the limitations of the present invention.

[0017] Reference below Figure 1-Figure 2 A mobile battery string detection device according to an embodiment of the present invention is described.

[0018] A mobile battery string detection device includes a substrate 3, a matched servo motor 1 and a reducer 2 are fixedly installed on the substrate 3, the output shaft of the reducer 2 is fixed with a driving pulley 4, and the substrate 3 is rotatably installed The driven pulley 13, the driving pulley 4 and the driven pulley 13 are connected by a synchronous toothed belt 12, the sliding block 5 is slidably mounted on the linear rail 14, and the inner and outer sides of the sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com