Bistable electrowetting display and preparation method thereof

An electrowetting display, bistable technology, applied in the directions of instruments, optical components, optics, etc., can solve the problems of complex manufacturing process, difficult production and preparation, difficult to realize industrialization and application promotion, etc., and achieve simple preparation process and structure. Simple, Steady State Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

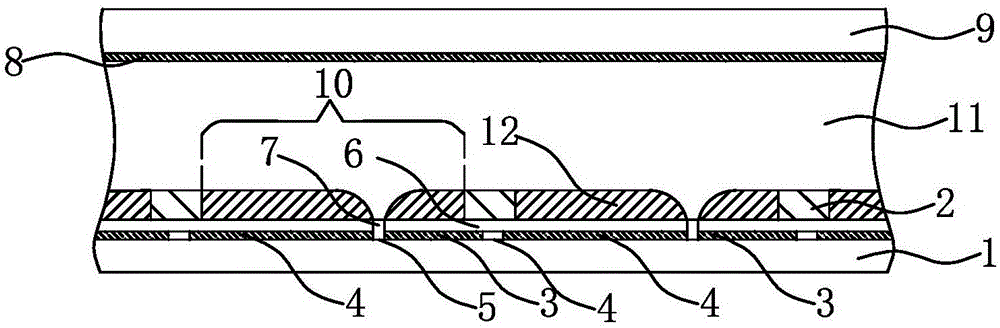

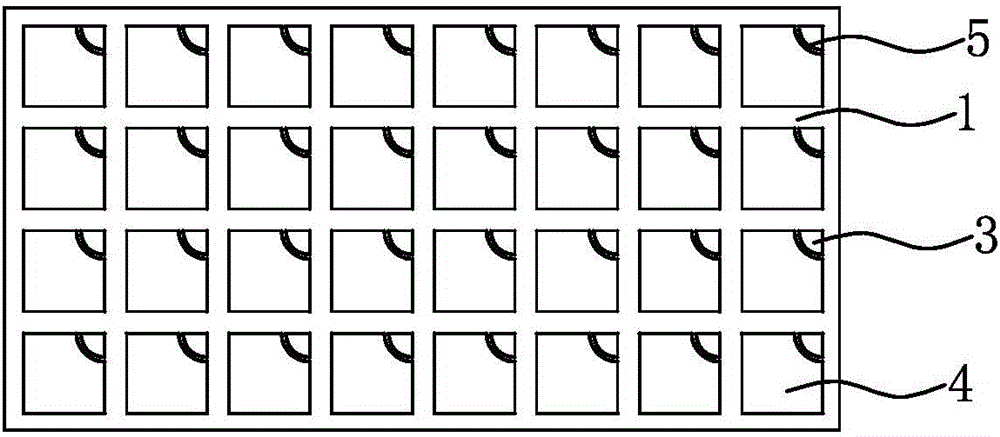

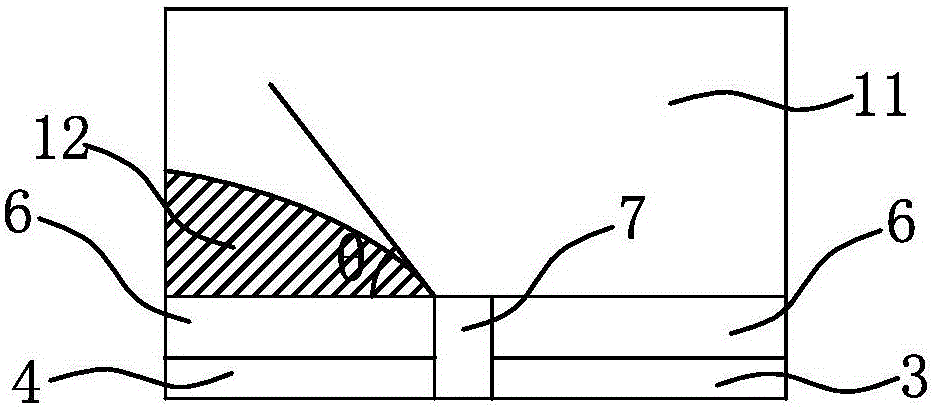

[0058] Take the substrate, the substrate of glass material is used in this embodiment, other materials with the same effect can be used as the substrate. A conductive layer is prepared by depositing a layer of silver, gold or ITO on different regions of the substrate surface by means of magnetron sputtering, etc., and the conductive layer includes a plurality of electrode pairs composed of a first electrode and a second electrode, each of which The electrode pairs are arranged corresponding to each pixel grid, the first electrode is arranged at a corner of the pixel grid, and an arc-shaped spacer strip is formed between the first electrode and the second electrode in each electrode pair. The thickness of the conductive layer can be controlled by the time of magnetron sputtering, and the film thickness is usually controlled between 25-100nm. The narrower the width of the arc-shaped spacer strips, the better, usually 2-10 microns. Wherein, the aperture ratio of the pixel is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com