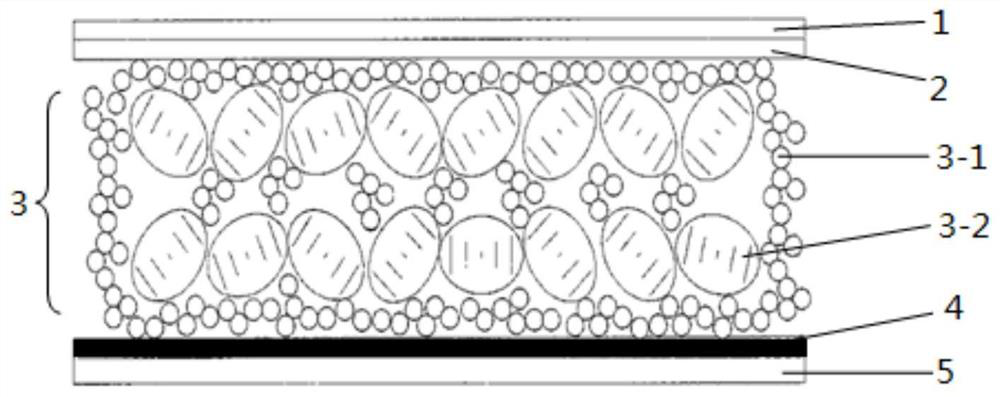

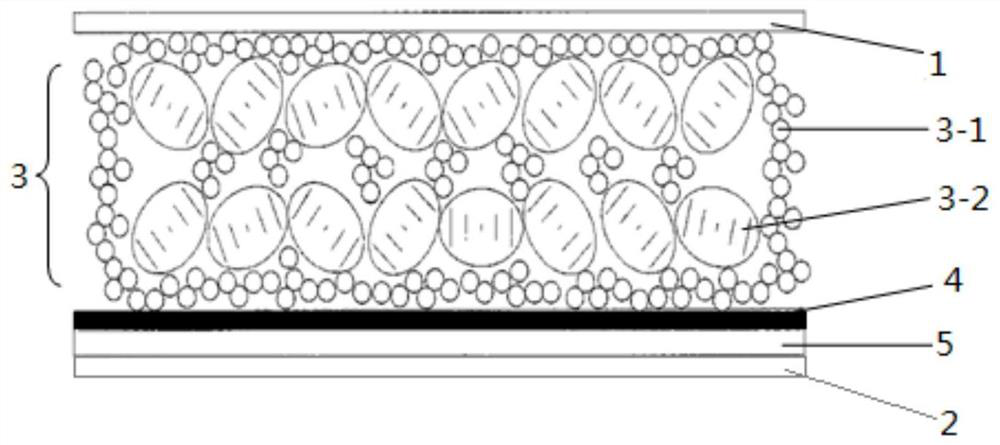

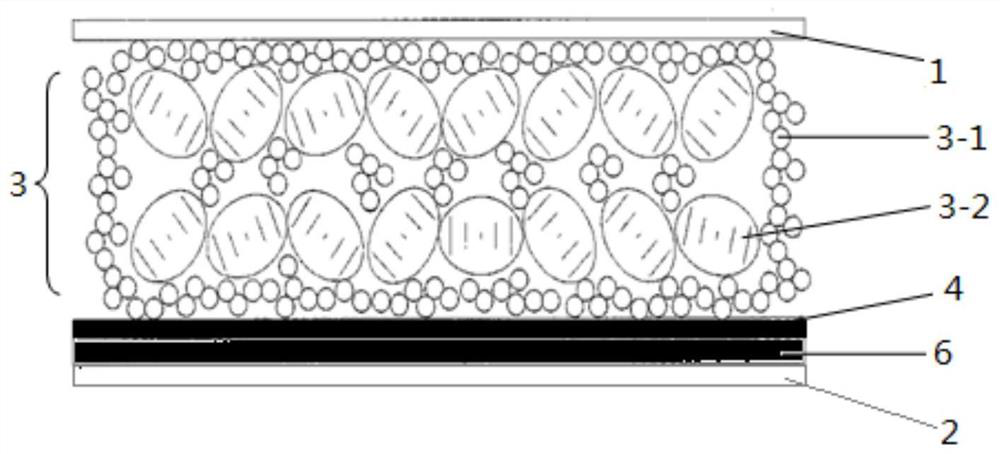

A kind of microcapsule liquid crystal display device and its application

A technology of liquid crystal display and microcapsules, which is applied in the direction of liquid crystal materials, instruments, chemical instruments and methods, etc., can solve the problems that liquid crystal molecules cannot completely return to the plane state and affect the contrast of devices, and achieve high reflectivity and contrast, and drive The effect of low voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] Each compound listed in Table 2 and its weight percentage are formulated into liquid crystal composition HNL-1:

[0097] Table 2 Liquid crystal composition formulation and its conventional performance parameters

[0098]

[0099]

[0100] Add appropriate optically active substances to the above-mentioned HNL-1 to adjust it to a cholesteric reflection wavelength of about 540nm, and mix 80mL of dichloromethane with 1g of PMMA prepolymer (brand CM-211) pre-dissolved with 1wt% poly After the 400mL aqueous solution of methacrylic acid (PMAA) is mixed, add 20g cholesteric phase liquid crystal, after mixing uniformly to form emulsion, adopt solvent evaporation method to remove dichloromethane, obtain the aqueous solution containing the liquid crystal microcapsule of about 10 μm in diameter (which contains about 50wt % of liquid crystal microcapsules). Then the prepared liquid crystal microcapsule aqueous solution and 30wt% bone glue aqueous solution are mixed uniformly ...

Embodiment 2

[0104] Each compound listed in Table 3 and its weight percentage are formulated into liquid crystal composition HNL-2:

[0105] Table 3 Liquid crystal composition formulation and its conventional performance parameters

[0106]

[0107]

[0108] Add appropriate optically active substances to the above-mentioned HNL-2 to adjust it to a cholesteric reflection wavelength of about 590nm, mix 80mL of dichloromethane with 1g of PMMA prepolymer (brand CM-207) dissolved in advance with 1wt% poly After the 400mL aqueous solution of methacrylic acid (PMAA) is mixed, add 20g cholesteric phase liquid crystal, after mixing uniformly to form emulsion, adopt solvent evaporation method to remove dichloromethane, obtain the aqueous solution containing the liquid crystal microcapsule of about 10 μm in diameter (which contains about 50wt % of liquid crystal microcapsules). Then the prepared liquid crystal microcapsule aqueous solution and 30wt% bone glue aqueous solution are mixed evenly ...

Embodiment 3

[0112] To the HNL-2 prepared in Example 2, add an appropriate optically active substance to adjust it to a cholesteric reflection wavelength of about 620nm, and dissolve 80mL of dichloromethane with 1g of PMMA prepolymer (brand CM-207) in advance and After mixing 400mL aqueous solution mixed with 1wt% polymethacrylic acid (PMAA), add 20g of cholesteric liquid crystal, mix uniformly to form an emulsion, remove methylene chloride by solvent evaporation, and obtain an aqueous solution containing liquid crystal microcapsules with a diameter of about 10 μm (which contains about 50wt% liquid crystal microcapsules). Then the prepared liquid crystal microcapsule aqueous solution and 30wt% bone glue aqueous solution are mixed uniformly at a volume ratio of 1:1, and set aside.

[0113] Select conductive PET-ITO with a thickness of 75 μm as the first substrate, place it on a film coating machine and place it flat, and use the screw printing technology to coat a layer of liquid crystal mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com