LED support, LED and LED packaging process

A technology of LED bracket and sealing glue, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of increasing the luminous angle of LED lamp beads, increasing material and labor costs, LED lamp bead vulcanization failure, etc., to achieve the increase of luminous angle , Increase the effect of reflection angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

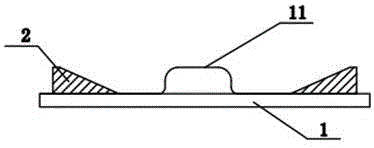

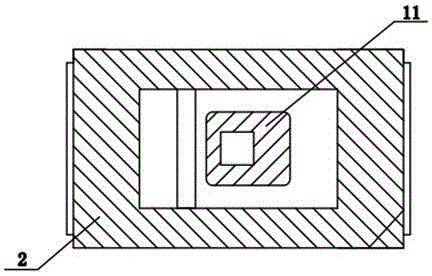

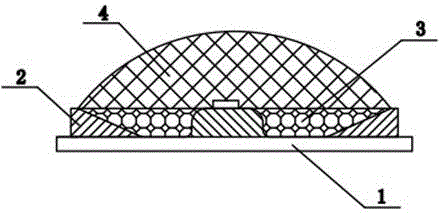

[0026] as shown in the picture figure 1 as well as figure 2 As shown, the present invention relates to an LED bracket, which includes a pin 1 and a cup body 2, wherein the cup body is arranged on the pin, and usually the cup body and the pin 1 are integrally formed, and the preferred molding materials of the two for the PPA.

[0027] Unlike common LED bracket pins which have a planar structure, the chip placement plane in the middle of the pins in this patent is composed of an upwardly raised platform structure, and placing chips on the raised platform can increase the LED light-emitting angle, A preferred forming method for the raised platform structure is punching from the back of the bracket. The cup body is arranged on the pins and fills the gap between the pins to form a bowl-cup structure.

[0028] The present invention also provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com