battery module

A battery module and cell module technology, applied to battery pack parts, circuits, electrical components, etc., can solve problems such as voltage loss, potential safety hazards, voltage acquisition board burnout, etc., to improve assembly efficiency and improve production quality , the effect of reducing the harm

Active Publication Date: 2018-06-05

SYST ELECTRONICS TECH ZHENJIANG CO LTD +1

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] ①Because of the polarity of the battery cell, it is necessary to judge the polarity of the battery cell before assembling, and then assemble it. The more modules there are, the more time it takes to judge the polarity. If there is a wrong judgment, the modules are installed backwards. , it will cause the entire string of voltage to be lost, and it will also cause the voltage acquisition board to be burned, and the production efficiency and quality will be affected;

[0004] ② It is impossible to effectively isolate the front and rear modules, and at the same time, there will be problems with the contact between modules;

[0005] ③There is no explosion vent slot in the cell bracket, so when the cell explodes, high temperature and high pressure cannot be eliminated, posing a safety hazard

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0028] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

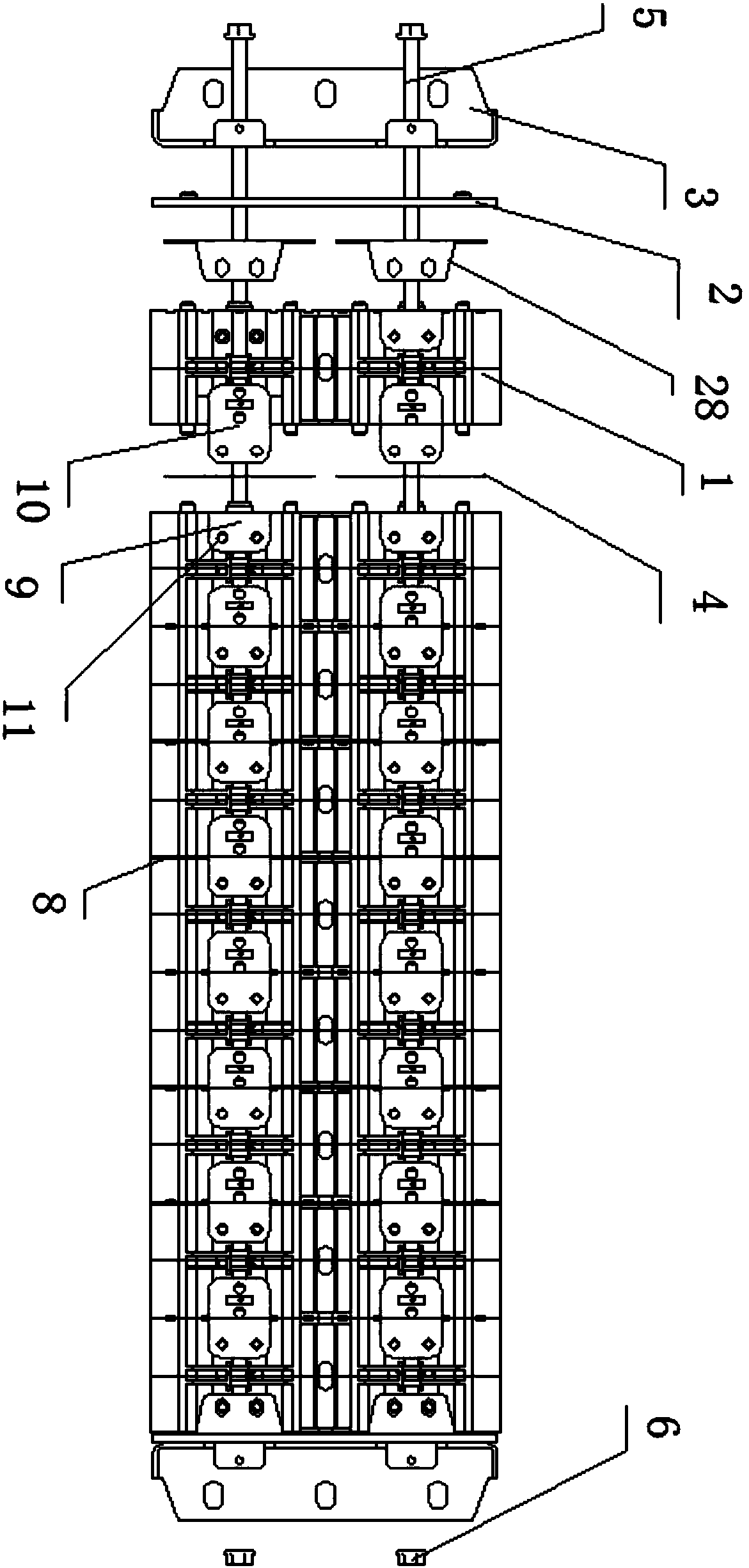

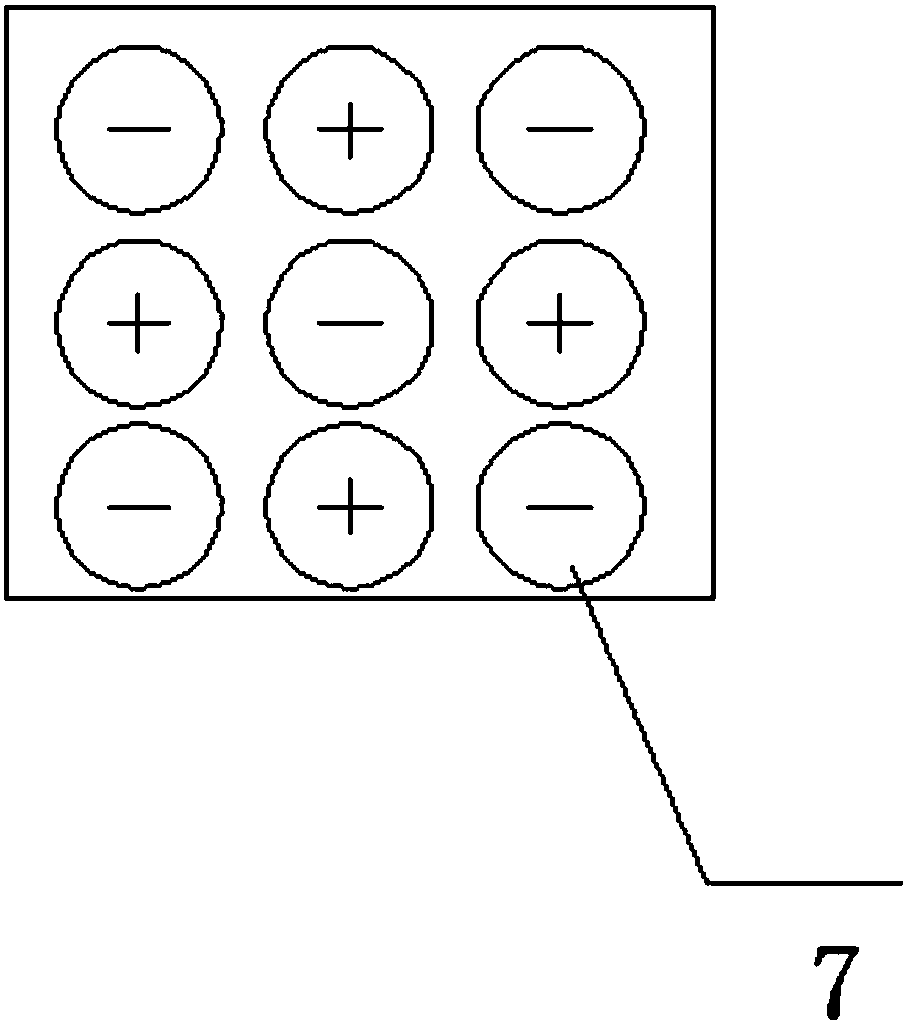

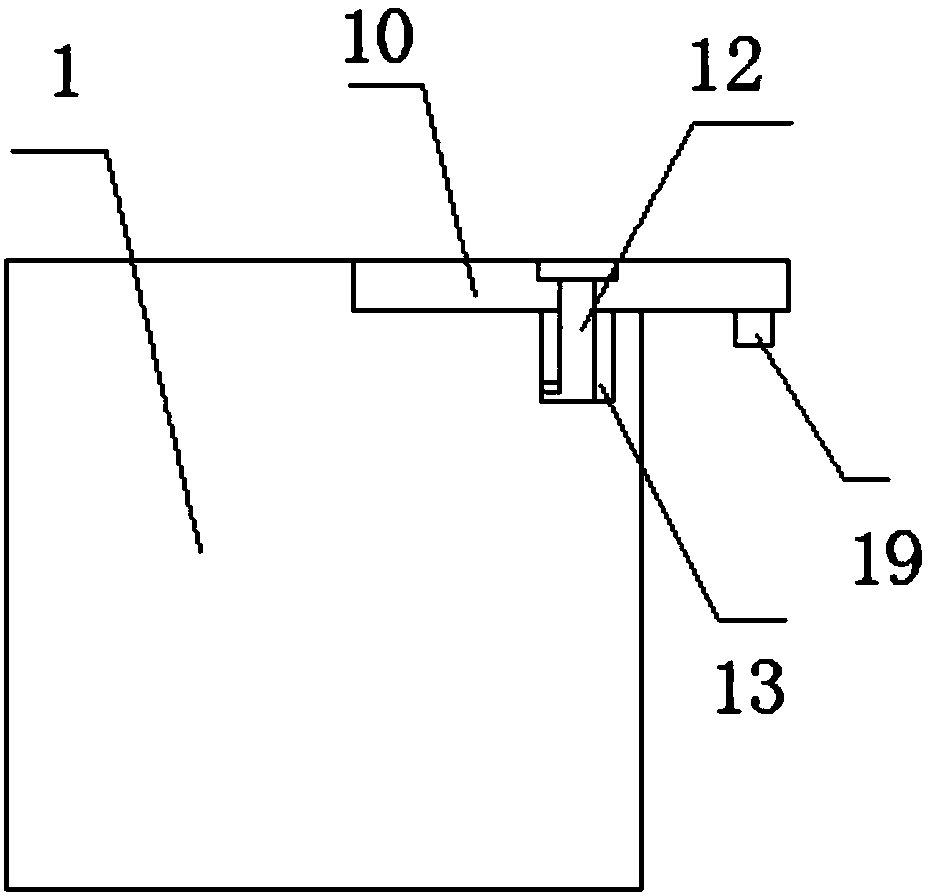

The invention relates to a new type of battery module, which includes a cell module, an insulating plate, a fixed steel frame, an aluminum sheet, a fixing bolt and a nut, and the cells in the cell module are alternately arranged with positive and negative poles, and any two adjacent The polarity setting between the cells is reversed, the number of cell modules is more than 3, aluminum sheets are arranged between adjacent cell modules, the number of aluminum sheets is one group less than the number of cell modules, and the copper There are two sets of copper sheets, insulating plates and fixed steel frames. The two sets of copper sheets, insulating plates and fixed steel frames are respectively arranged at both ends of the two outermost cell modules from the inside to the outside, and are connected by bolts and nuts. The cooperation between them is fixed, which improves the assembly efficiency and improves the safety performance at the same time.

Description

technical field [0001] The invention relates to a battery module, in particular to a novel battery module with good safety performance. Background technique [0002] When the existing modules are assembled into a module, there are the following problems: [0003] ①Because of the polarity of the battery cell, it is necessary to judge the polarity of the battery cell before assembling, and then assemble it. The more modules there are, the more time it takes to judge the polarity. If there is a wrong judgment, the modules are installed backwards. , it will cause the entire string of voltage to be lost, and it will also cause the voltage acquisition board to be burned, and the production efficiency and quality will be affected; [0004] ② It is impossible to effectively isolate the front and rear modules, and at the same time, there will be problems with the contact between modules; [0005] ③The battery support has no explosion vent slots, and when the battery explodes, high ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M2/10H01M2/34H01M2/12H01M50/20H01M50/342H01M50/597

CPCH01M50/20H01M50/342H01M50/597Y02E60/10

Inventor 史云福陈沈常昊

Owner SYST ELECTRONICS TECH ZHENJIANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com