Integrated high-voltage shielding electrical connector socket

An electrical connector, integrated technology, applied in the direction of connection, parts and circuits of the connection device, can solve the problems of hidden safety hazards of the connection structure, unsatisfactory shielding effect, low production efficiency, etc., to achieve high use value and reduce parts. Variety, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solution and advantages of the present invention clearer, the specific implementation manners of the present invention will be clearly and completely described below.

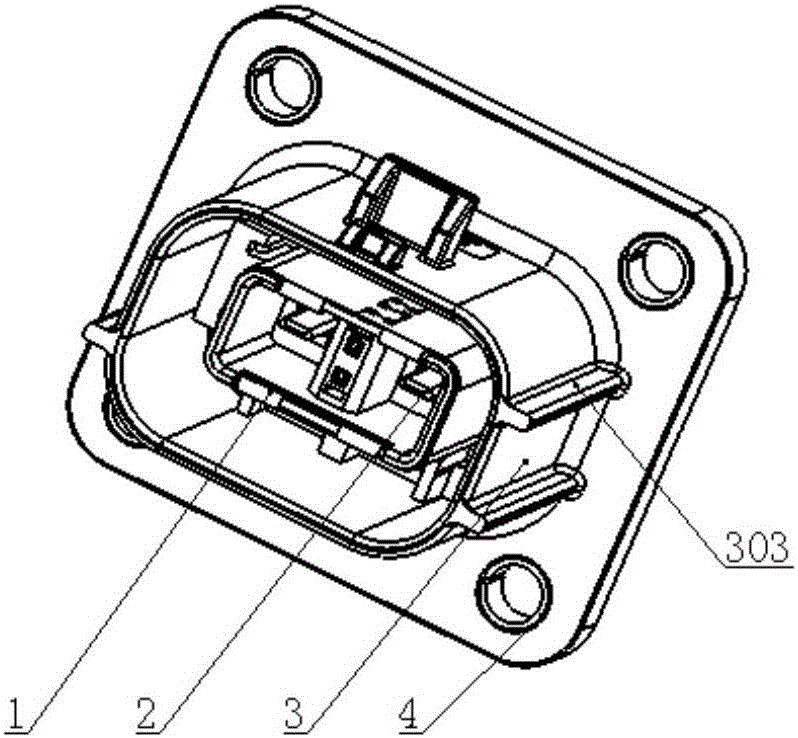

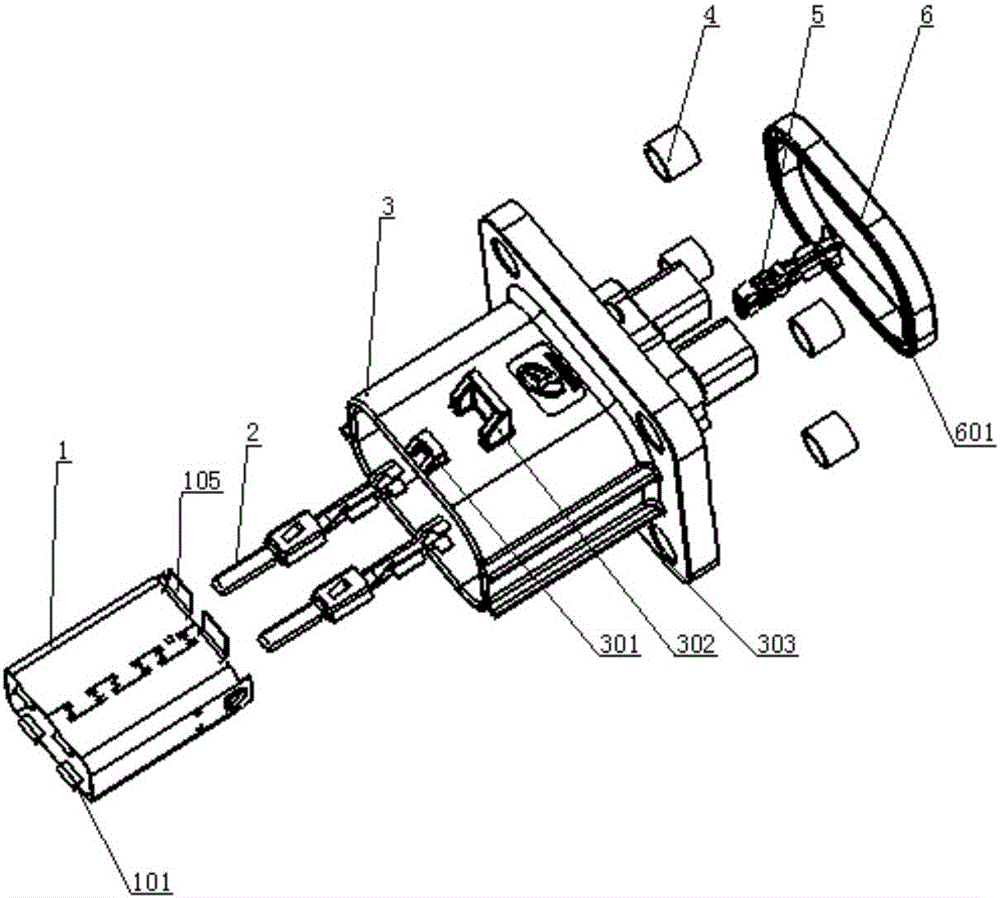

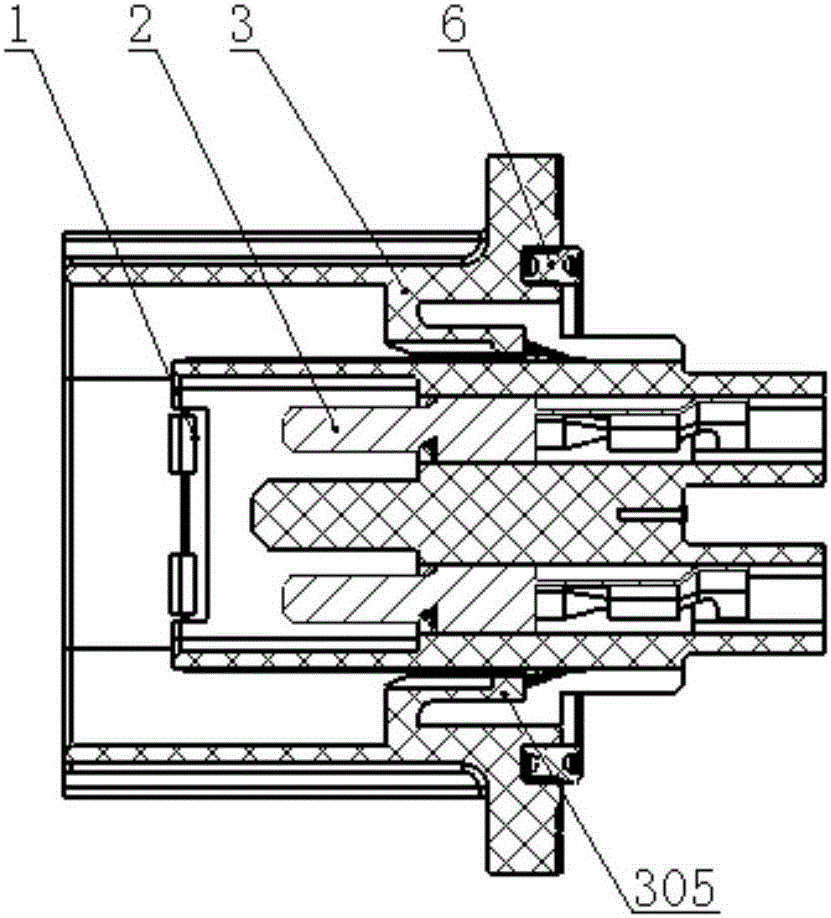

[0035] Figure 1 ~ Figure 3 A schematic diagram of the structural principle of the integrated high-voltage shielded electrical connector socket provided by the embodiment of the present invention, Figure 4 and Figure 5 Schematic diagram of the structural principle of the integrated socket housing, Figure 6 It is a schematic diagram of the structure principle of the metal shield. Such as Figure 1 to Figure 6 As shown, the integrated high-voltage shielded electrical connector socket includes a metal shield 1 , a power pin 2 , an integrated socket housing 3 , a screw sleeve 4 , a signal jack 5 , and a socket sealing ring 6 . The one-piece socket shell 3 is integrally injection-molded by the socket shell and the mounting plate, and the one-piece socket shell 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com