Spindle retainer for a readjustment device

A technology for maintaining devices and compensating adjustments, which is applied in friction clutches, clutches, mechanically driven clutches, etc., and can solve problems such as excessive load on shaft sleeves, fatigue cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

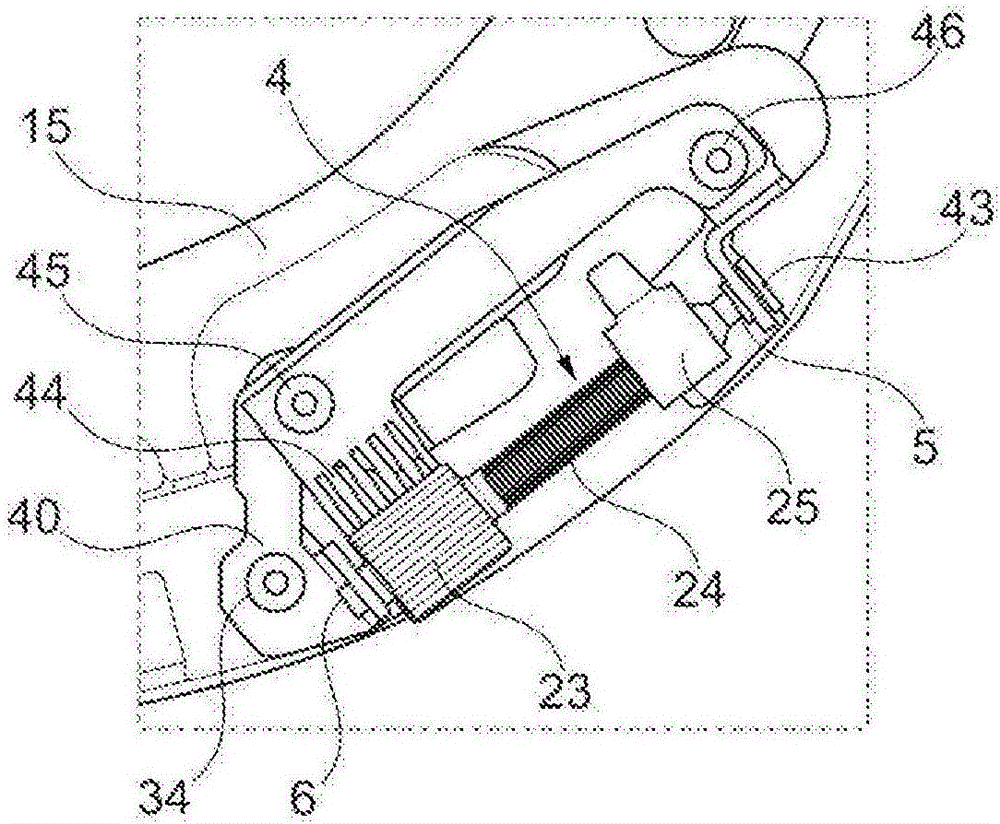

[0056] figure 1 A conventional receptacle 40 is shown in , which is fastened to an extruded plate 15 by means of a first fastening element 34 , a second fastening element 45 and a third fastening element 46 . The screw shaft 4 with the drive pinion 23 and the screw drive 24 is held with a first end 5 in a bushing 43 . In this view, locking pawls 44 can be seen which, via the drive pinion 23 , secure the position of the spindle nut 25 on the spindle drive 24 of the spindle 4 in an adjusted position.

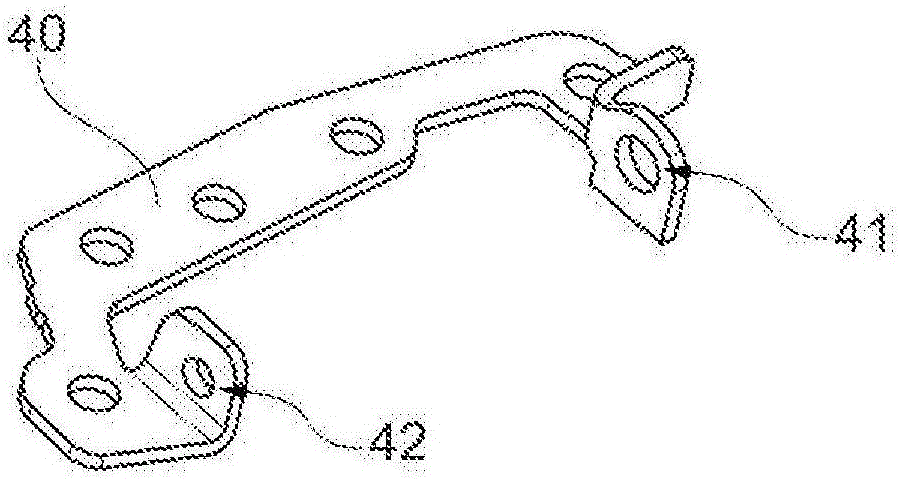

[0057] figure 2 shown in figure 1 A conventional receptacle 40 as in , wherein a first opening 41 and a conventional second opening 42 can be recognized here. It is clear that in this case the screw shaft 4 has to be pushed through the conventional first opening 41, wherein the drive pinion 23 and the screw nut 25 can then be inserted as figure 1 to the screw shaft 4 as shown in .

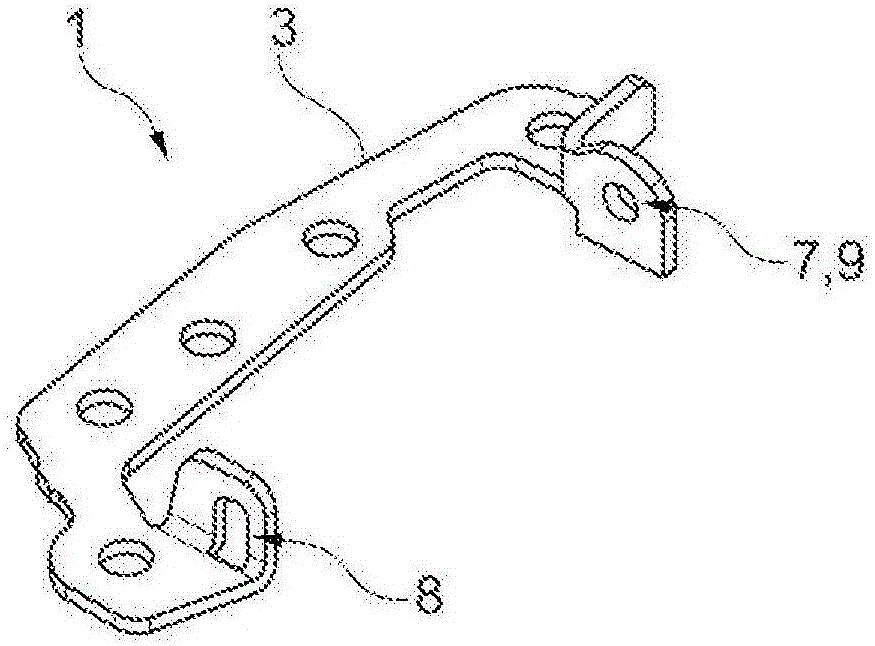

[0058] image 3 shows the receptacle 3 of the screw holding device 1 according to the invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com