Compensation adjustment device for friction clutch

A friction clutch, compensation and adjustment technology, applied in the direction of friction clutch, clutch, mechanical drive clutch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

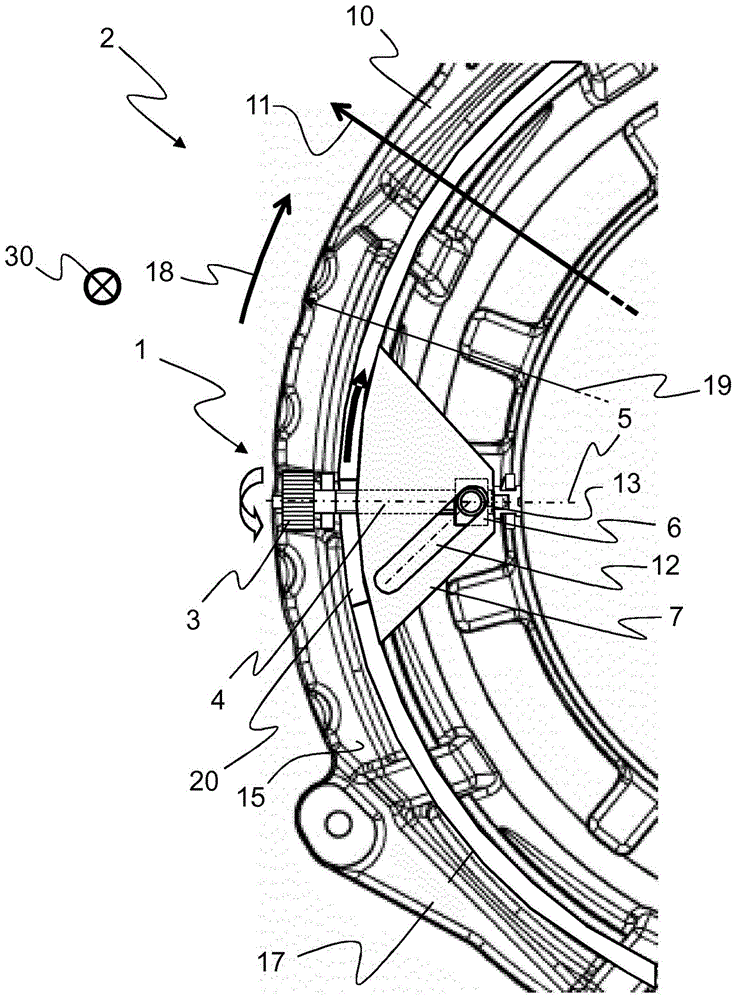

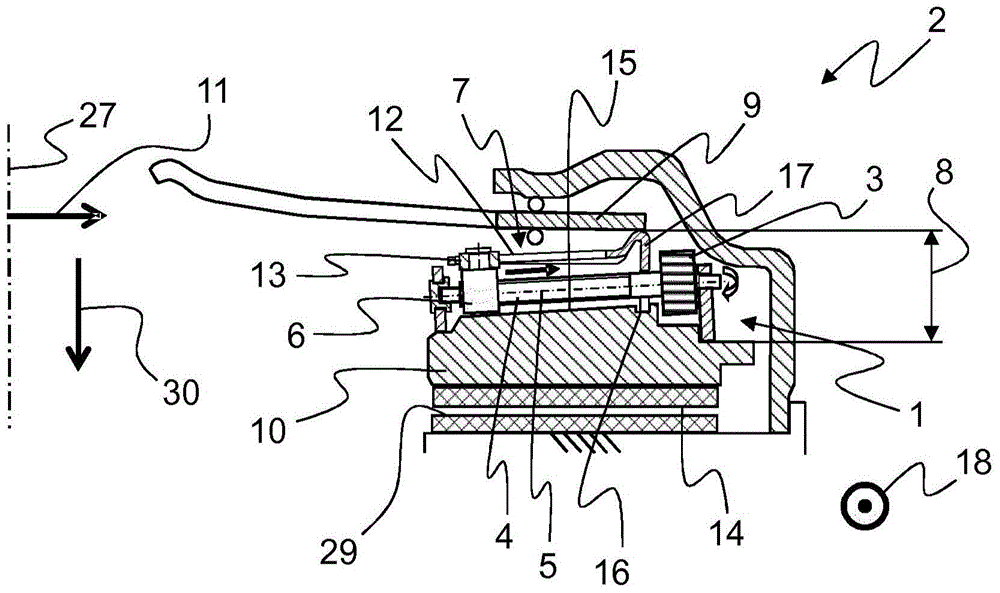

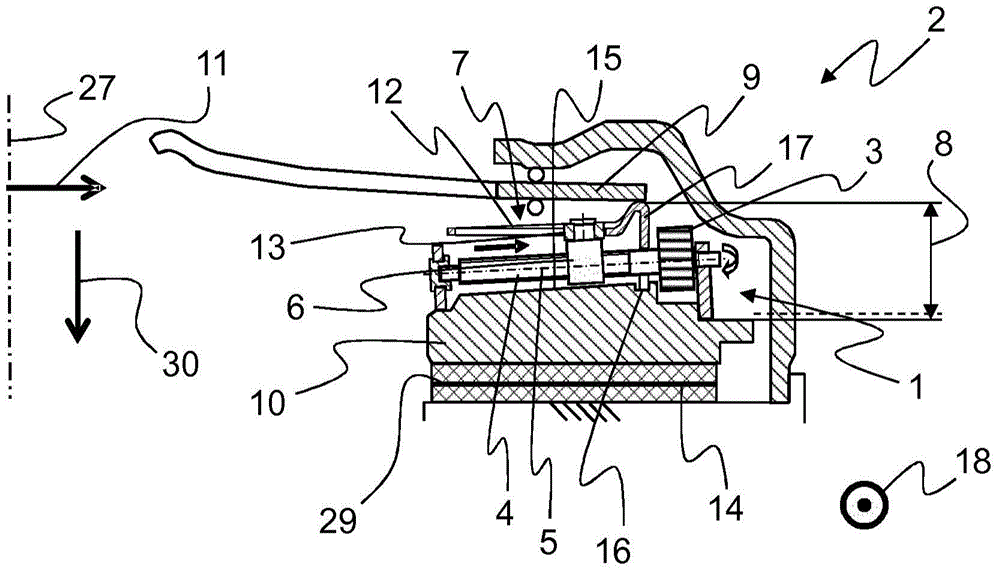

[0046] figure 1 The compensation adjustment device 1 is shown in a friction clutch 2 shown in part, the compensation adjustment device 1 being arranged on the rear side 15 of the pressure plate 10 . The axial direction 5 of the compensation adjusting spindle 4 is arranged parallel to the radial direction 11 of the friction clutch 2 . The rotatable drive 3 is arranged on the outer circumference 19 of the pressure plate 10 . The compensation adjustment screw 4 extends through a groove 20 in the ramp ring 17 . By twisting the drive 3 , the spindle nut 6 is moved on the compensating adjusting spindle 4 in the axial direction 5 outwards (indicated by the arrow pointing to the left in the figure). The slide 13 thus moves in the link 12 of the adjusting unit 7 in the axial direction 5 or in the radial direction 11 of the friction clutch 2 . The ramp ring 17 is thus moved in a circumferential direction 18 which is indicated by an arrow on the ramp ring 17 . The bevel 16 of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com