Flexible thermal insulation aerogel material and preparation method and application thereof

An airgel and flexible technology, applied in the direction of electrical components, conductors, insulated cables, etc., can solve the problems of complex preparation process, high cost, and unsatisfactory heat insulation performance, and achieve good flexibility, low cost, and avoid easy to break sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

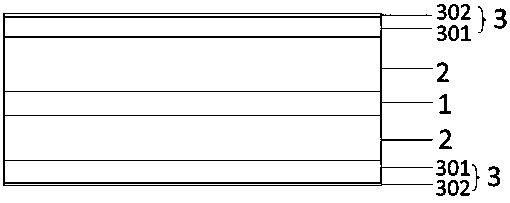

Image

Examples

Embodiment 1

[0035] A method for preparing a flexible heat-insulating airgel material, comprising the steps of:

[0036] S1. Gradually add 1 part of phosphoric acid into the mixed system of 10 parts of tetraethyl orthosilicate and 200 parts of deionized water, then stir at 1500 r / min for 2 hours, and under the catalysis of phosphoric acid, hydrolyze and preshrink to obtain a silicon solution;

[0037] S2. Mix 10 parts of vinyl chloride with the silicon solution, and stir at 1500 r / min for 4 hours to obtain a silicon dioxide precursor solution.

[0038] S3. The silicon dioxide precursor solution is placed in a vacuum oven and dried at a temperature of 105°C to remove the residual deionized water in the solution; then placed in a muffle furnace at a temperature of 900°C in an air atmosphere, and calcined for 3h to The organic components in the solution are removed to obtain a silica fiber film.

[0039] S4. Shred the silica fiber film and mix it with 100 parts of deionized water, and then u...

Embodiment 2

[0051] A method for preparing a flexible heat-insulating airgel material, comprising the steps of:

[0052] S1. Gradually add 2 parts of phosphoric acid into the mixed system of 8 parts of ethyl tetrasilicate and 120 parts of deionized water, then stir at 1500r / min for 2 hours, and under the catalysis of phosphoric acid, hydrolyze and preshrink to obtain a silicon solution;

[0053] S2. Mix 8 parts of vinyl chloride with the silicon solution, and stir at 1500 r / min for 4 hours to obtain a silicon dioxide precursor solution.

[0054] S3. The silicon dioxide precursor solution is placed in a vacuum oven and dried at a temperature of 105°C to remove the residual deionized water in the solution; then placed in a muffle furnace at a temperature of 900°C in an air atmosphere, and calcined for 3h to The organic components in the solution are removed to obtain a silica fiber film.

[0055] S4. Shred the silica fiber film and mix it with 200 parts of deionized water, and then use a hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com