Novel industrial hair curling equipment with automatic supply function

A new type of curling technology, applied in hairdressing equipment, curling or perming devices, clothing, etc., can solve problems that require manual management, and achieve the effect of saving automatic curling, liberating manpower, and saving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

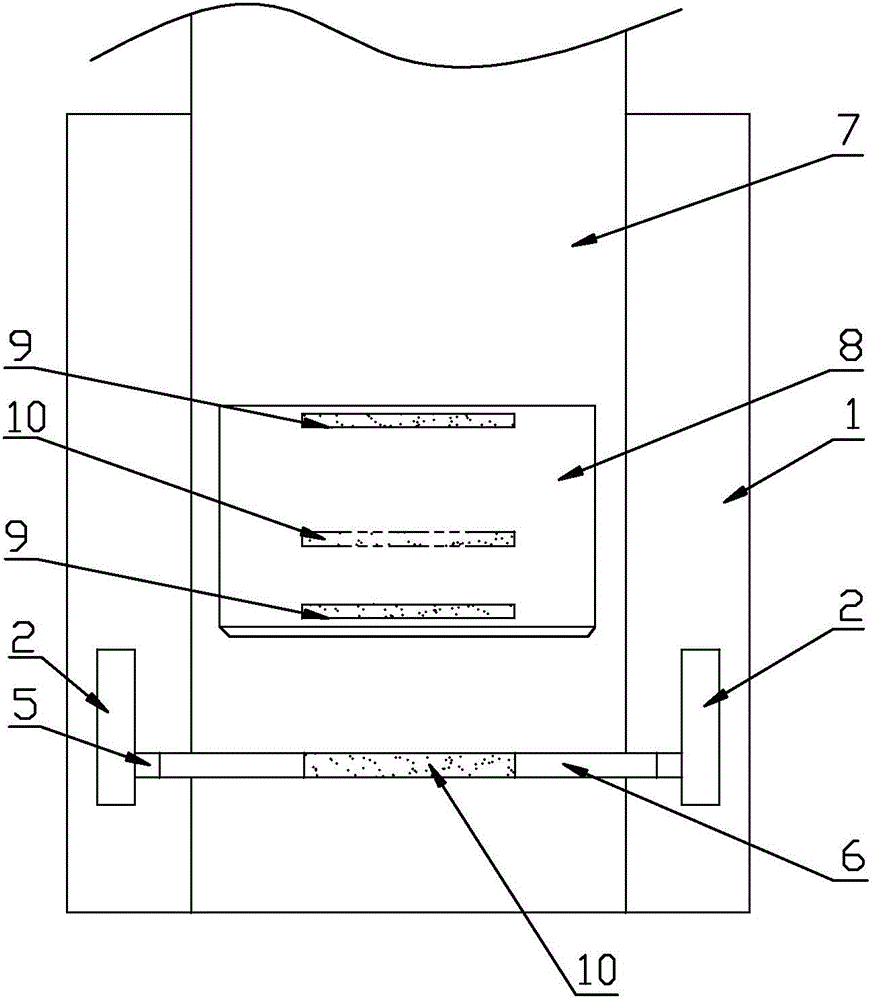

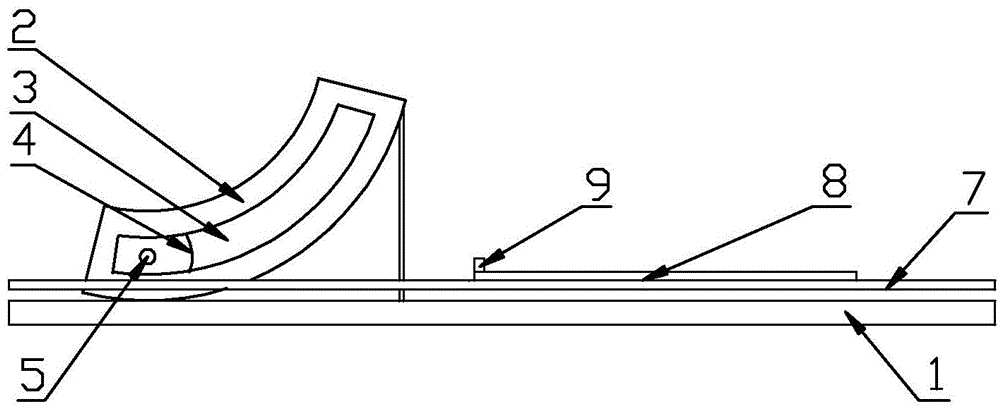

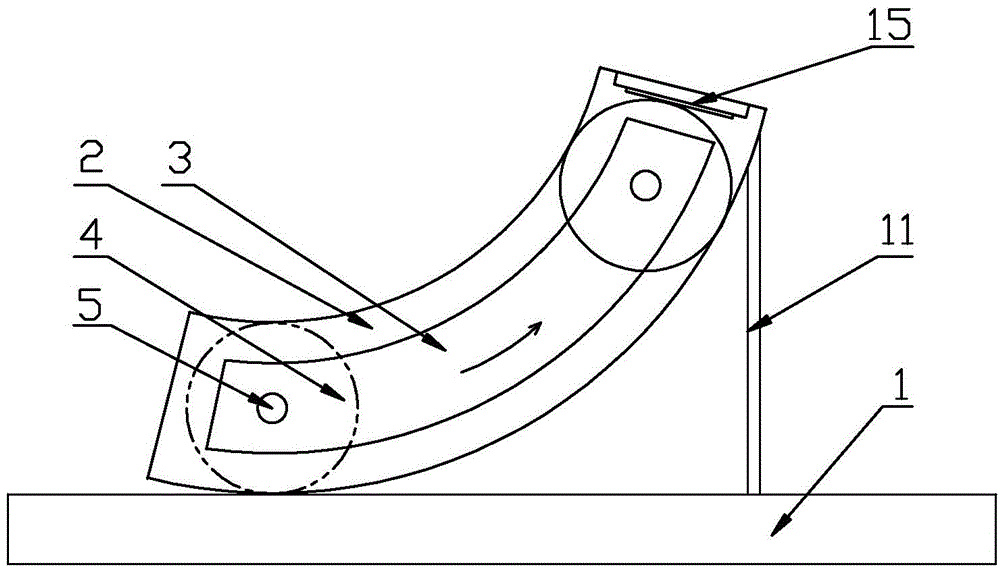

[0027] Such as Figure 1-4 As shown, a new type of industrial curling equipment for automatic feeding, which includes a base 1, two raised chambers 2 are arranged on both sides of the top of the base 1, the two chambers 2 are opposite, and the chamber 2 An arc-shaped opening 3 is respectively opened on the opposite surface of each chamber 2, and rollers 4 are movable respectively in each chamber 2, and the center position of each roller 4 is fixedly connected to a central shaft 5, and one end of each central shaft 5 extends Out of the arc-shaped opening 3, a curling stick 6 is engaged and connected between the two central shafts 5, and a feeding device is installed on the top surface of the base 1, and the feeding device includes a conveyor belt 7 and a wrapping cloth 8. A wrapping cloth 8 is placed on the conveyer belt 7, and the front end of the front of the wrapping cloth 8 is provided with a sticking part 9, and the sticking part 9 is arranged perpendicular to the plane wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com