A spray system for a dishwasher with partition washing function and the dishwasher

A technology of spraying system and dishwasher, applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, applications, etc., can solve the problems of increased energy consumption and washing time, and achieve reduction The effect of washing energy consumption, reducing washing time, and improving washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

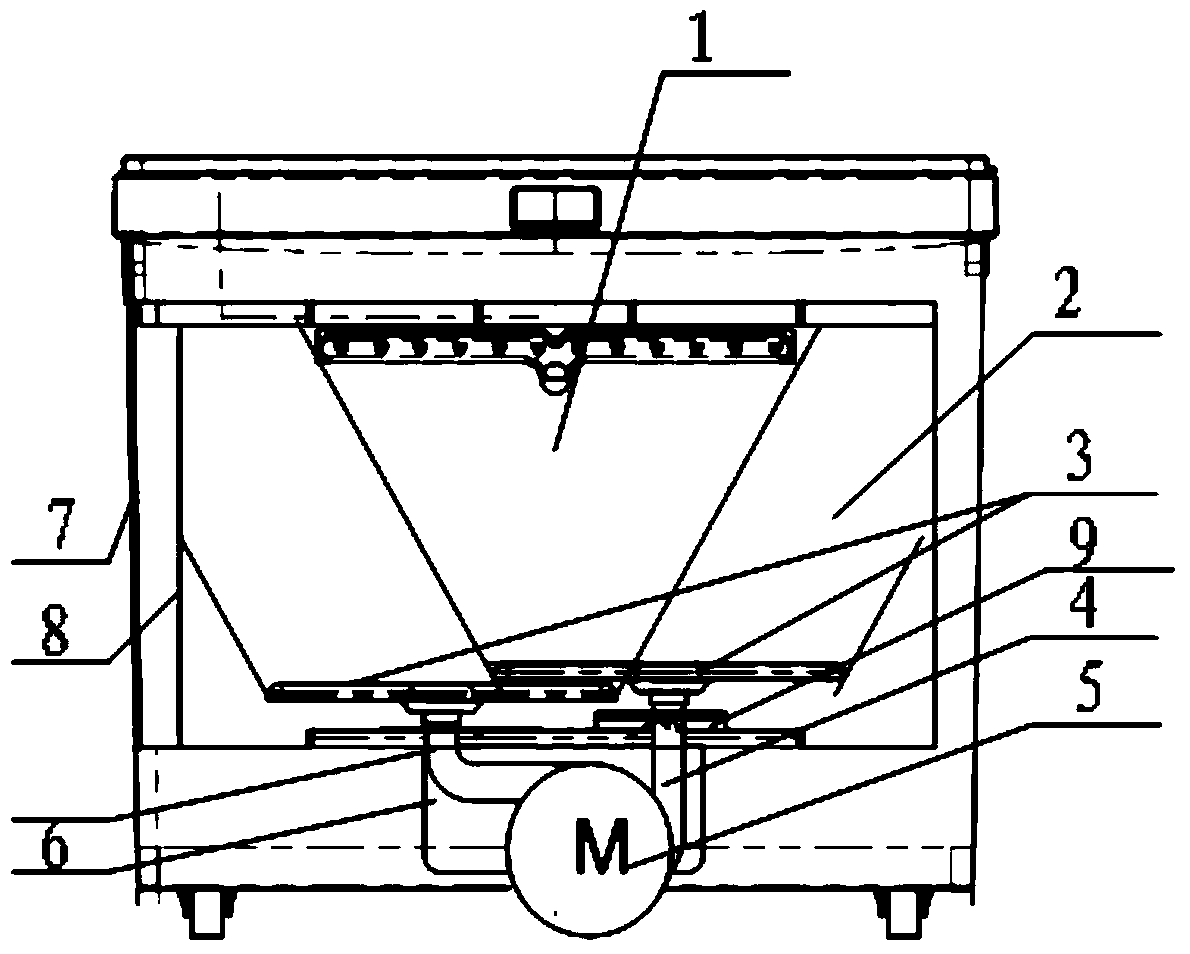

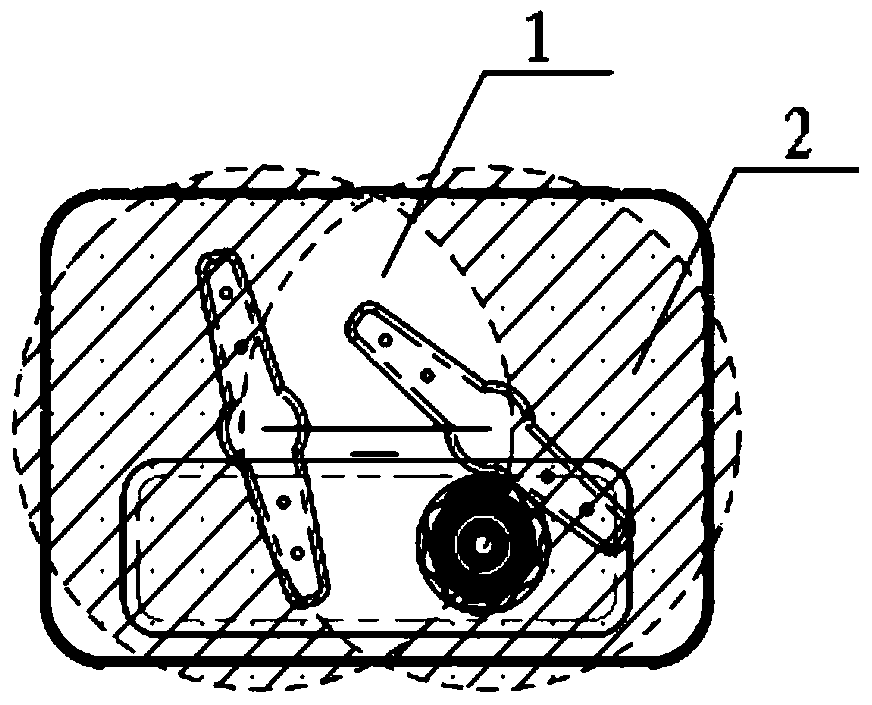

[0029] Such as Figure 1-2 As shown, a dishwasher spray system with partition washing function includes: at least one quick wash area 1 and two general wash areas 2 located outside the quick wash area 1; the quick wash area 1 is used for cleaning For items to be cleaned that are relatively difficult to clean such as oil stains, the general washing area 2 is used to clean relatively clean items to be cleaned, so that items to be cleaned with different cleaning difficulties are cleaned in the same batch, so as to solve the problem that the user has a relatively large number of items to be cleaned. Less, and the difficulty of cleaning is different, it is necessary to prolong the cleaning time.

[0030] Specifically, each general cleaning area 2 is provided with a shower, and the general cleaning area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com