Deodorization device and method for removing high-concentration foul gas and VOC waste gas

A malodorous gas, high-concentration technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as failure, biological deodorization is easy to be poisoned, etc., and achieve the effect of avoiding gas escape or short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical objectives, technical solutions and advantages of the present invention clearer, preferred embodiments of the present invention are described in detail below.

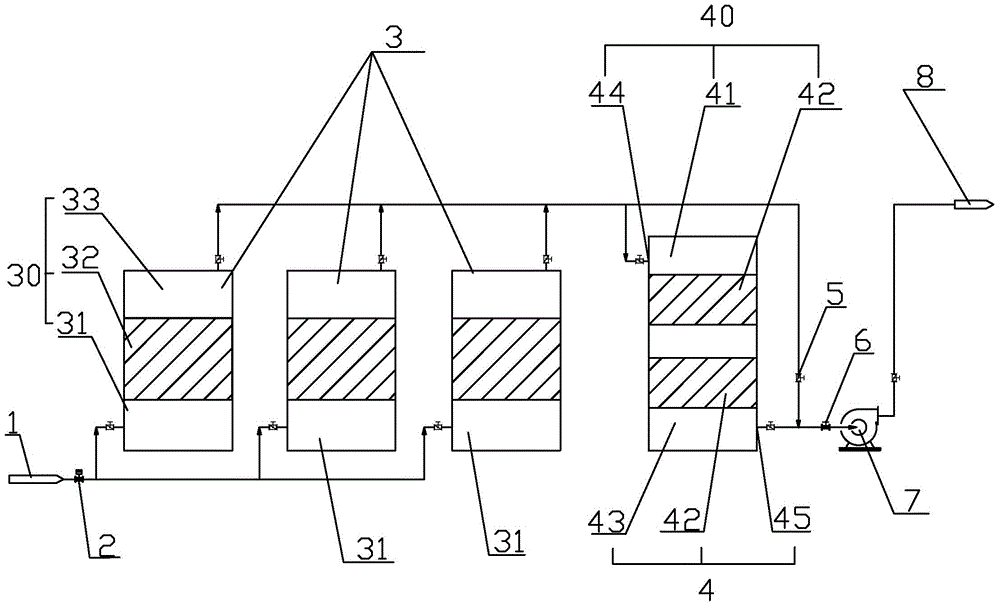

[0042] Deodorizer

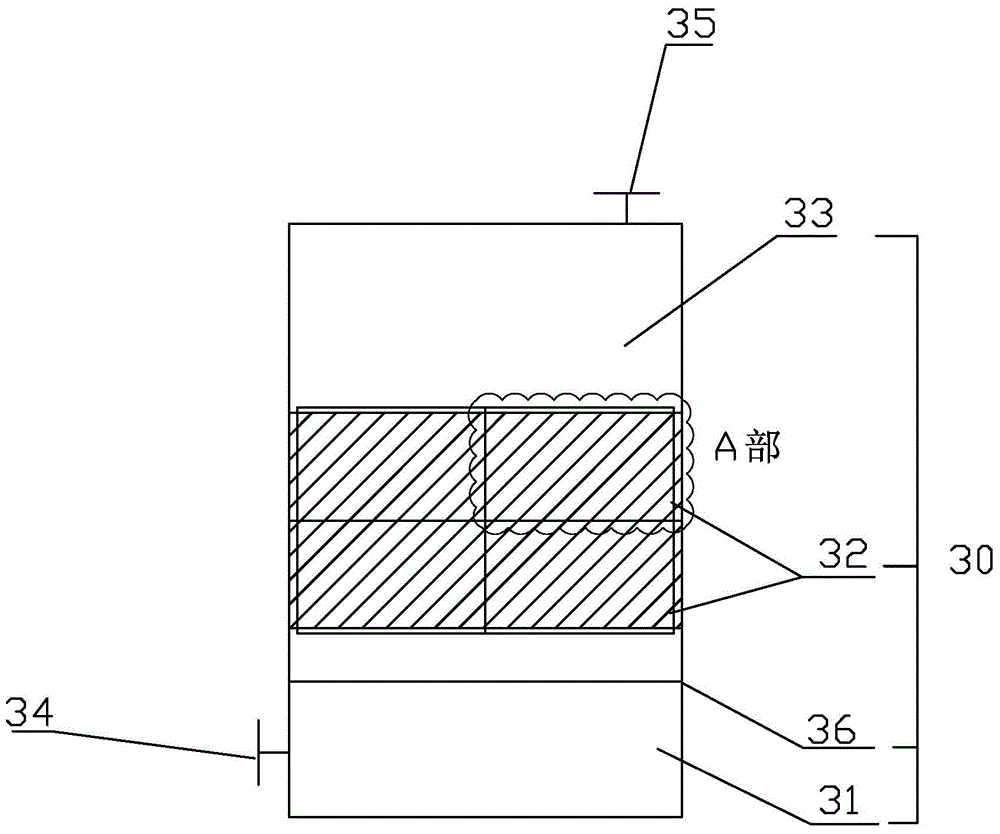

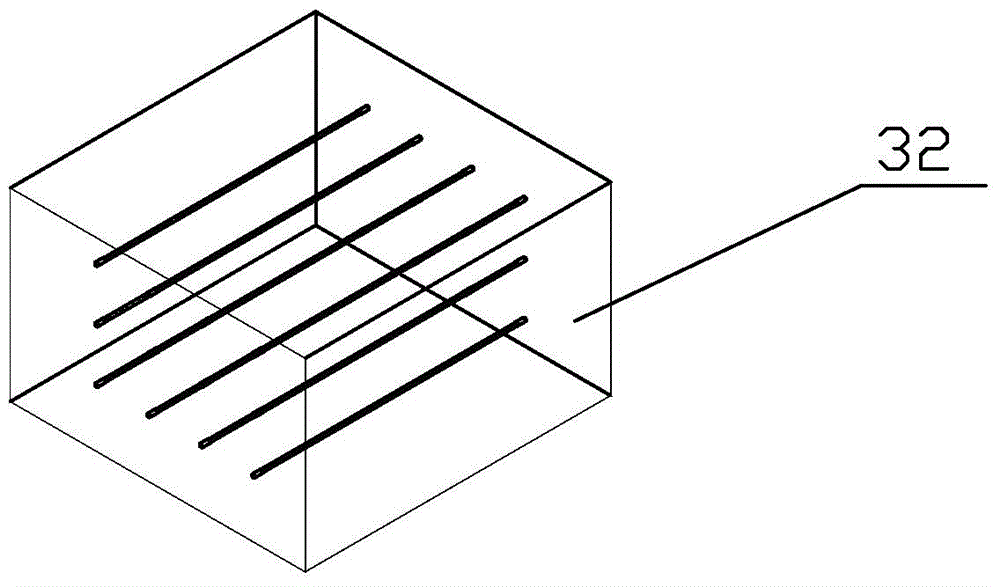

[0043] Such as figure 1 As shown, the deodorizing device for removing high-concentration malodorous gas and VOC waste gas of the present invention is connected with a vacuum ultraviolet light reaction chamber 3 (hereinafter referred to as the VUV reaction chamber) and a carbon-manganese mixed filter tower 4 in sequence; the VUV reaction chamber The number of 3 is one or more. When there are several VUV reaction chambers 3, they are connected in parallel. The VUV reaction chamber 3 includes a reaction chamber 30 and an air inlet 34 and an air outlet 35 communicating with the reaction chamber 30, the air inlet 34 is connected to the gas supply end 1; the carbon-manganese mixed filter tower 4 It includes a tower body 40 , a filter tower inlet 44 and a filter t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com