Replaceable fluid supply device

A fluid supply device and fixing seat technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low production efficiency, time-consuming and laborious, slow production speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The detailed description and technical content of the present invention are described below with accompanying drawings. However, the attached drawings are provided for reference and illustration only, and are not intended to limit the present invention.

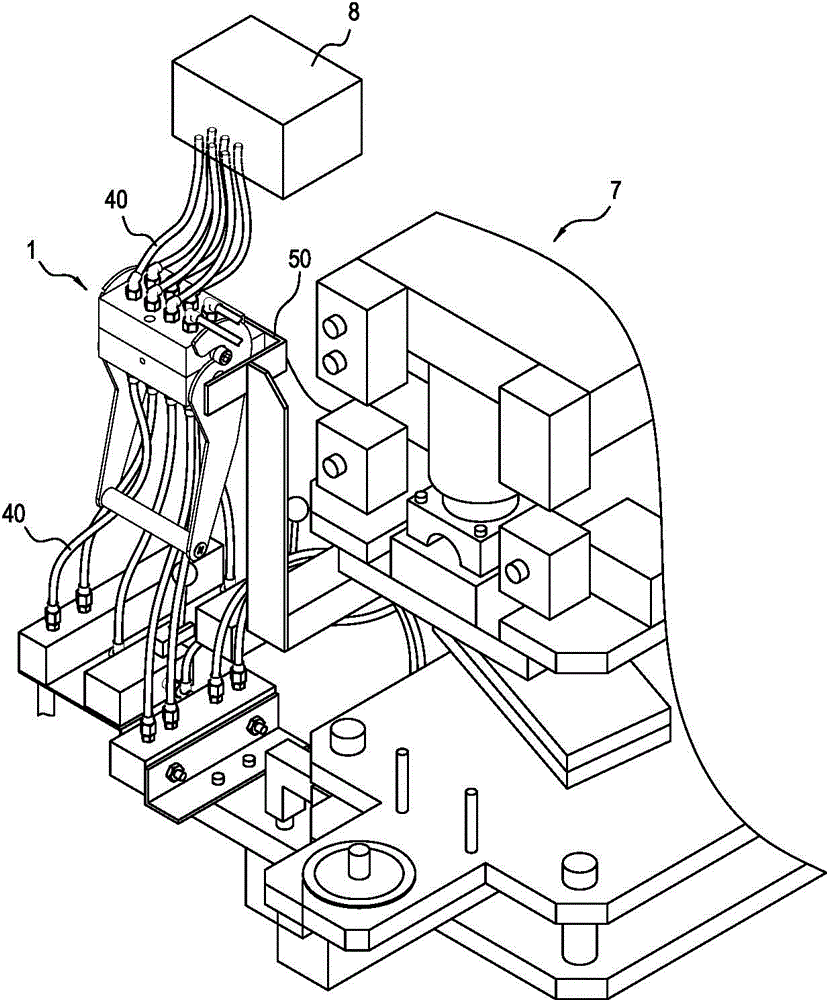

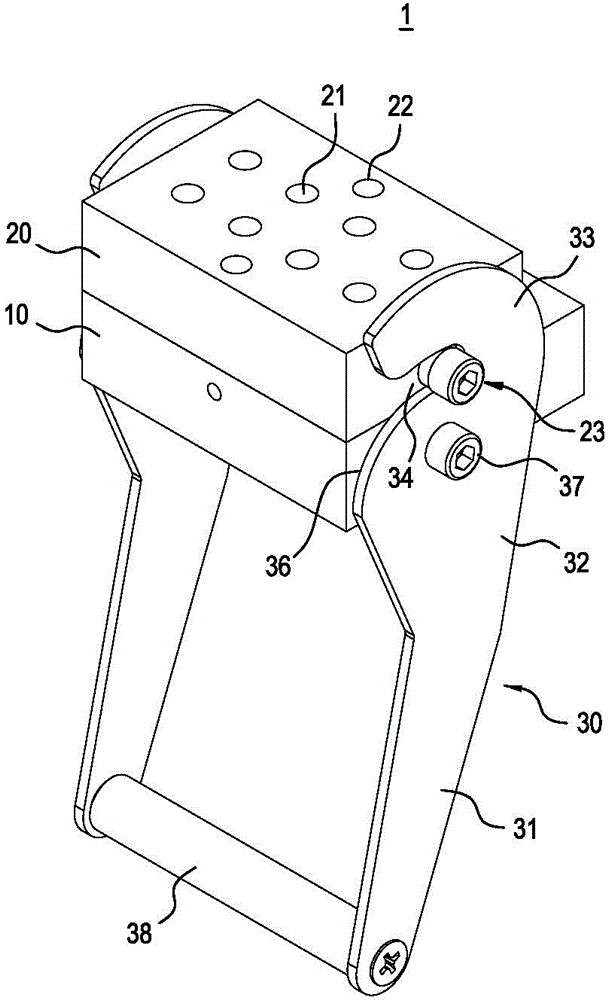

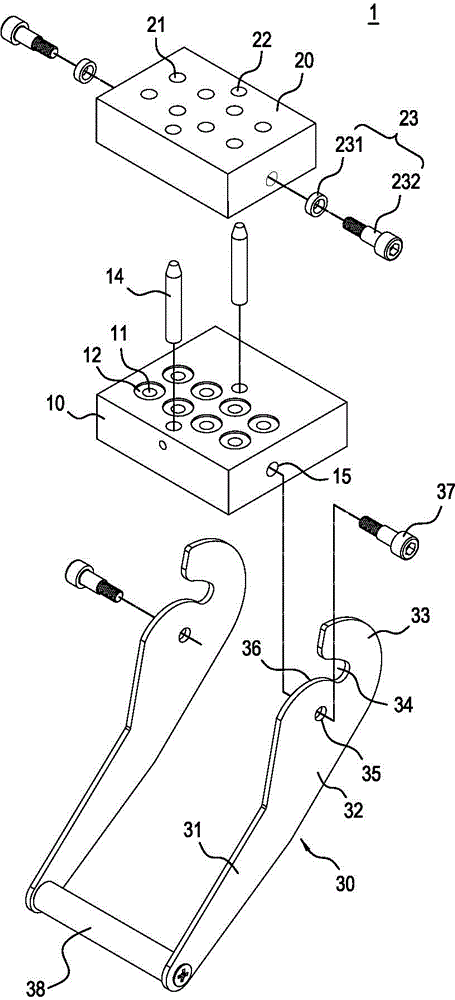

[0051] see Figure 1 to Figure 3 As shown, the present invention provides a replaceable fluid supply device, which can be applied to a welding tool 7, but is not limited to such a tool. The replaceable fluid supply device 1 mainly includes a fixing seat 10 . A detachable module 20 and a turning arm 30 .

[0052] The fixing seat 10 is made of metal and other materials, and is roughly in the shape of a rectangular block. Two rows of parallel through holes 11 are provided on the fixing seat 10, and a recess 12 is formed around the outer periphery of each through hole 11. This cavity 12 is provided with a sealing ring 13 (see Figure 5 ) installation, in addition, a positioning pin 14 is respectively connected to the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com