Rotating platform structure

A technology of rotating platforms and substrates, which is applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of poor precision of processing objects, inaccurate angle division, and division angle error, etc., to ensure accurate angle division Accuracy and precision of processing objects, improving work efficiency, and the effect of multi-angle processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described below through examples, and it should be understood that the examples listed here are only used to explain the present invention, and are not intended to limit the present invention.

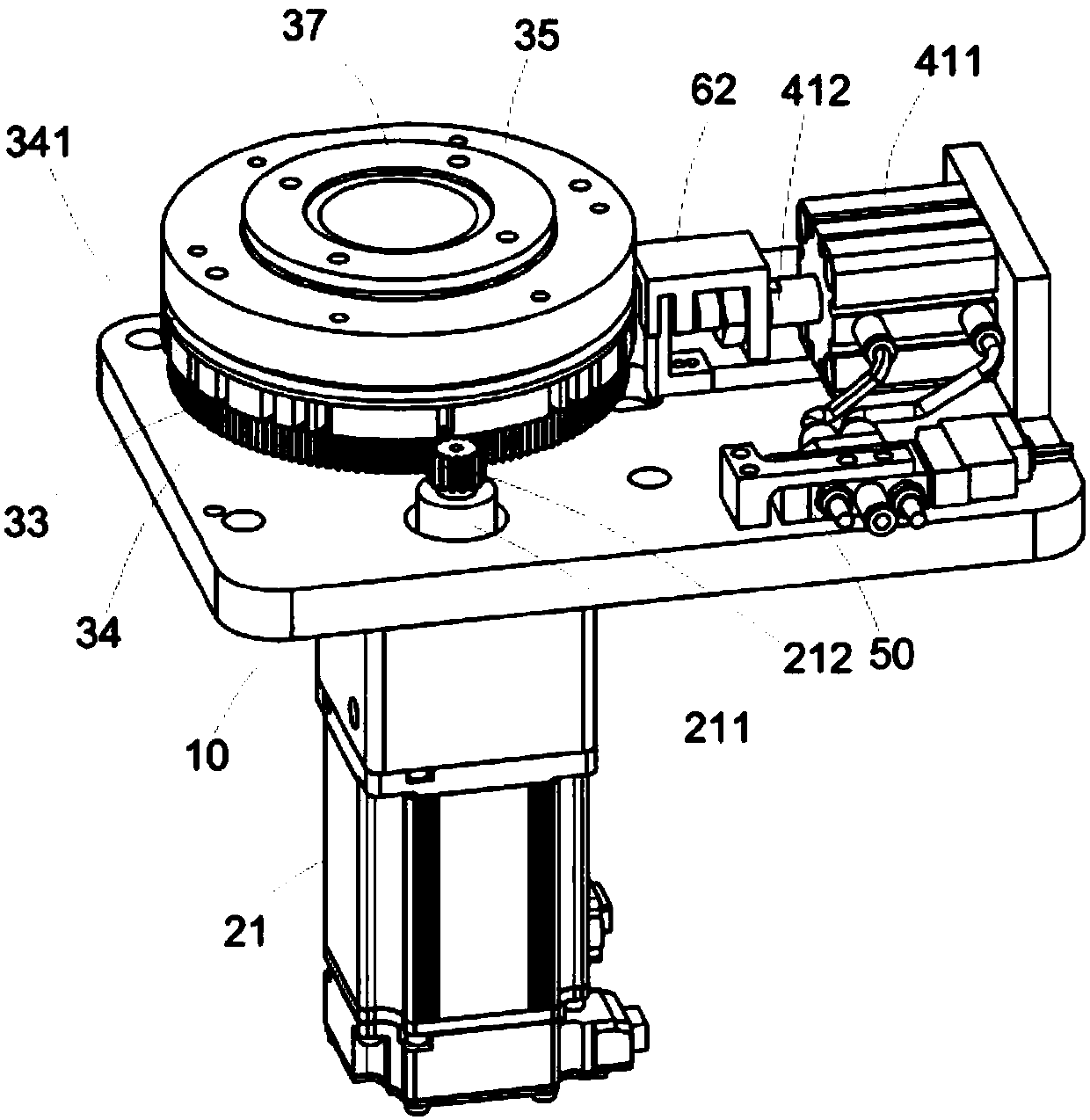

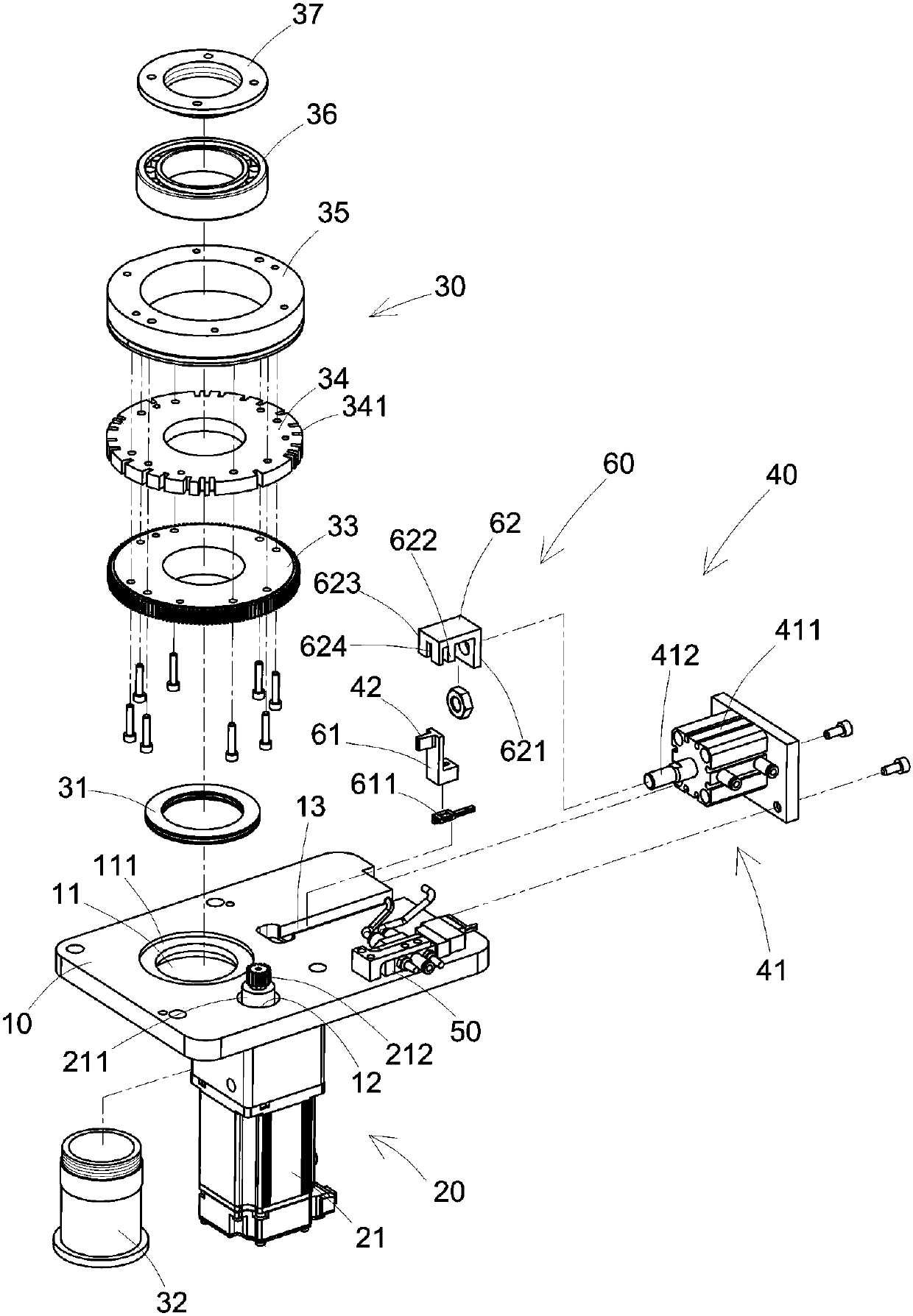

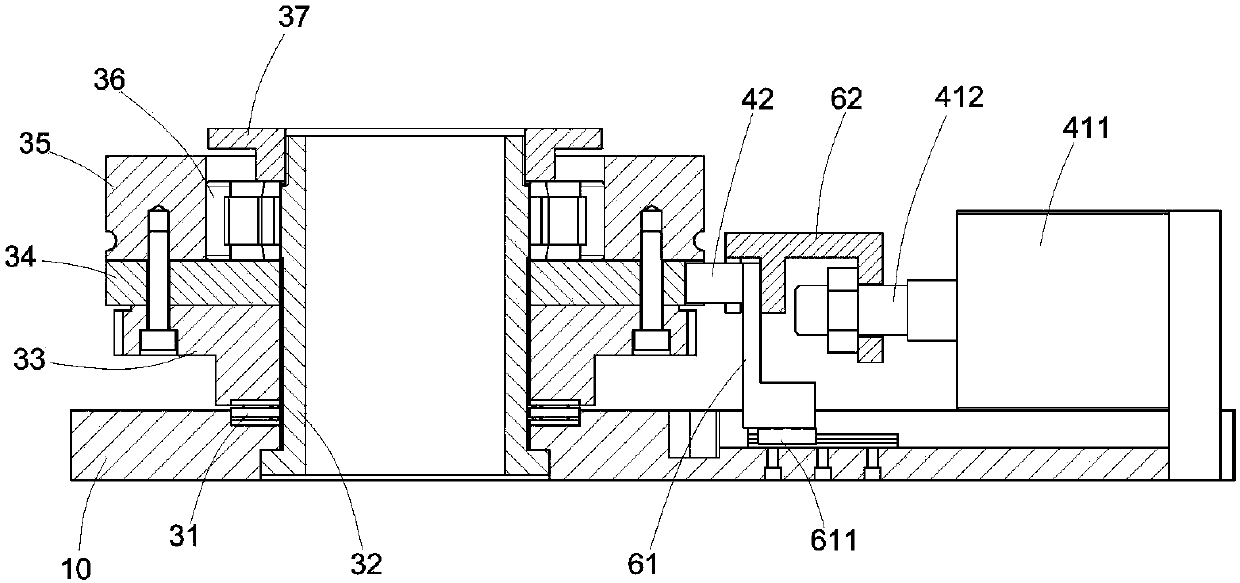

[0033] refer to Figure 1 to Figure 5 As shown, the present invention provides a rotating platform structure, including: a base plate 10, a first power source 20, a rotating group 30, and a stopper group 40; the base plate 10 is provided with a hollow hole 11 and a through hole 12, The top surface of the hollow hole 11 has a recess 111; the first power source 20 is fixed at the position of the perforation 12 of the substrate 10; the rotating group 30 is composed of a first bearing 31, a hollow sleeve 32, A first disc 33, a second disc 34 with several notches 341 equiangularly arranged on the outer periphery, a third disc 35, a second bearing 36 and a cover 37 are formed, and the first bearing 31 is installed on The recessed portion 111 of the base plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com