Patents

Literature

33results about How to "Rapid manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

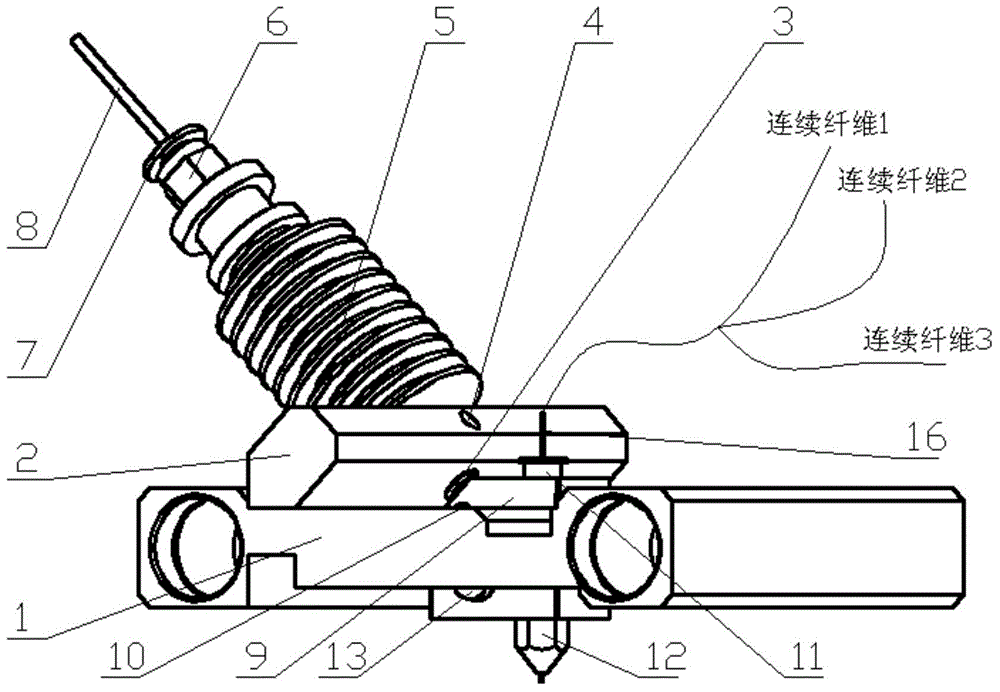

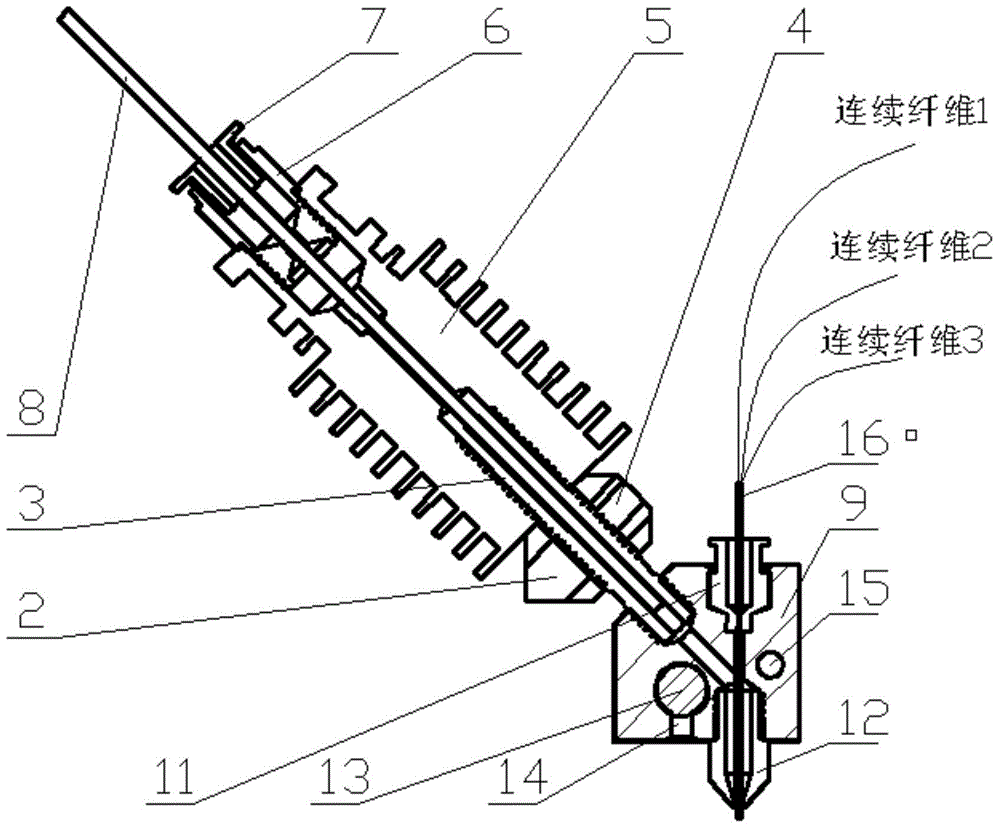

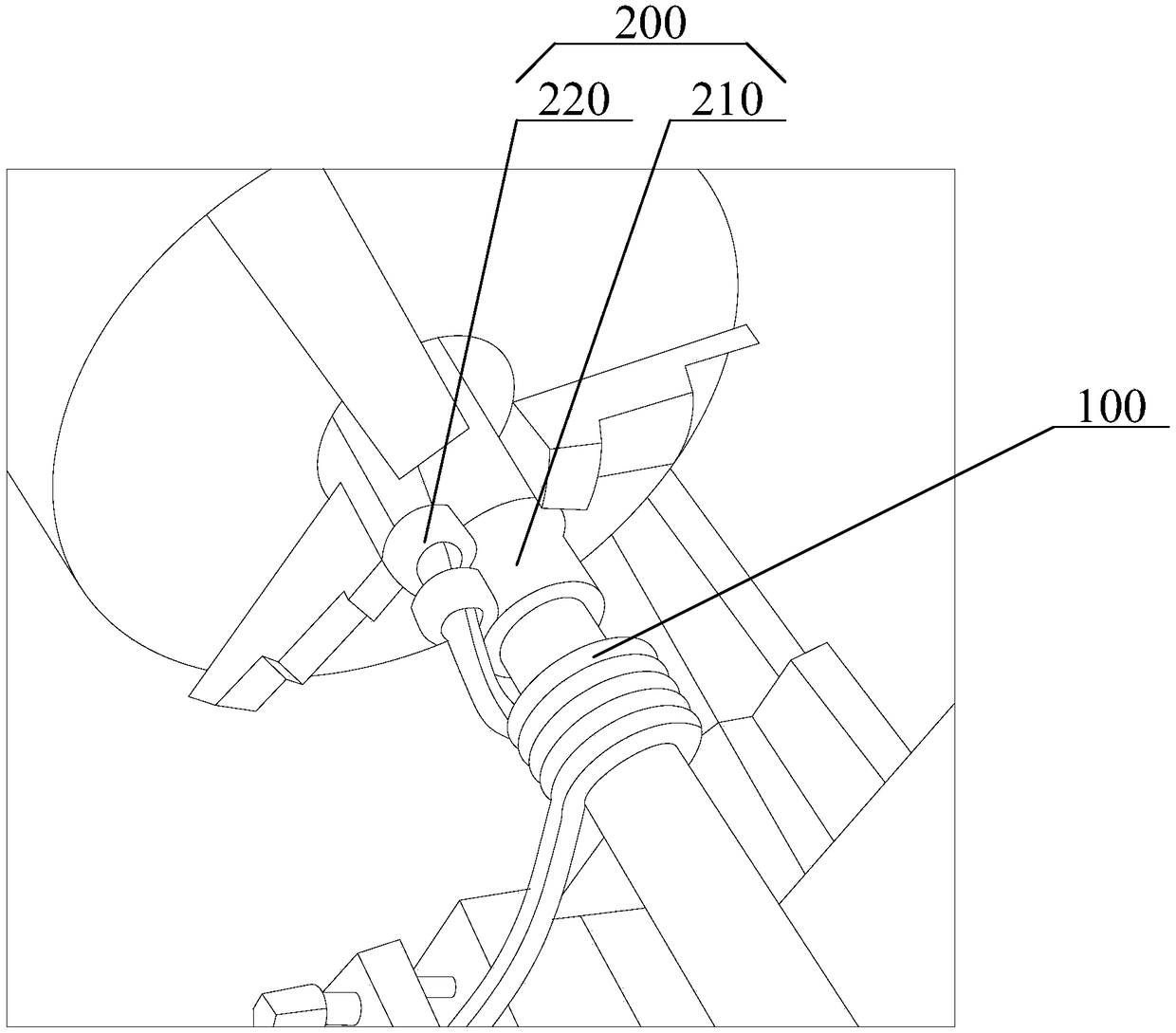

3D printing head for continuous-fiber-reinforced intelligent composite material and use method of 3D printing head

InactiveCN104441658ARapid manufacturingControlling the direction of reinforcing fibersFiber bundleElectrical and Electronics engineering

A 3D printing head for a continuous-fiber-reinforced intelligent composite material comprises a 3D printing head support, wherein the 3D printing head support is connected with a 3D printing head truss, the middle of the 3D printing head truss is connected with a throat pipe, two ends of the throat pipe are connected with a heat dissipation frame and a heating block respectively, the heat dissipation frame is connected with a thermoplastic base material, the thermoplastic base material passes through a first inner channel formed by the heat dissipation frame and the throat pipe, a needle, a copper nozzle, a heating pipe and a heat-sensitive sensor are connected onto the heating block, continuous fiber bundles pass through a second inner channel formed by the needle and the copper nozzle, the continuous fiber bundles and thermoplastic base material in a molten state are composited at the front end of the copper nozzle and extruded from an outlet of the copper nozzle, and quick manufacturing of parts which are made of the composite material and adopts complex structures is realized.

Owner:XI AN JIAOTONG UNIV +1

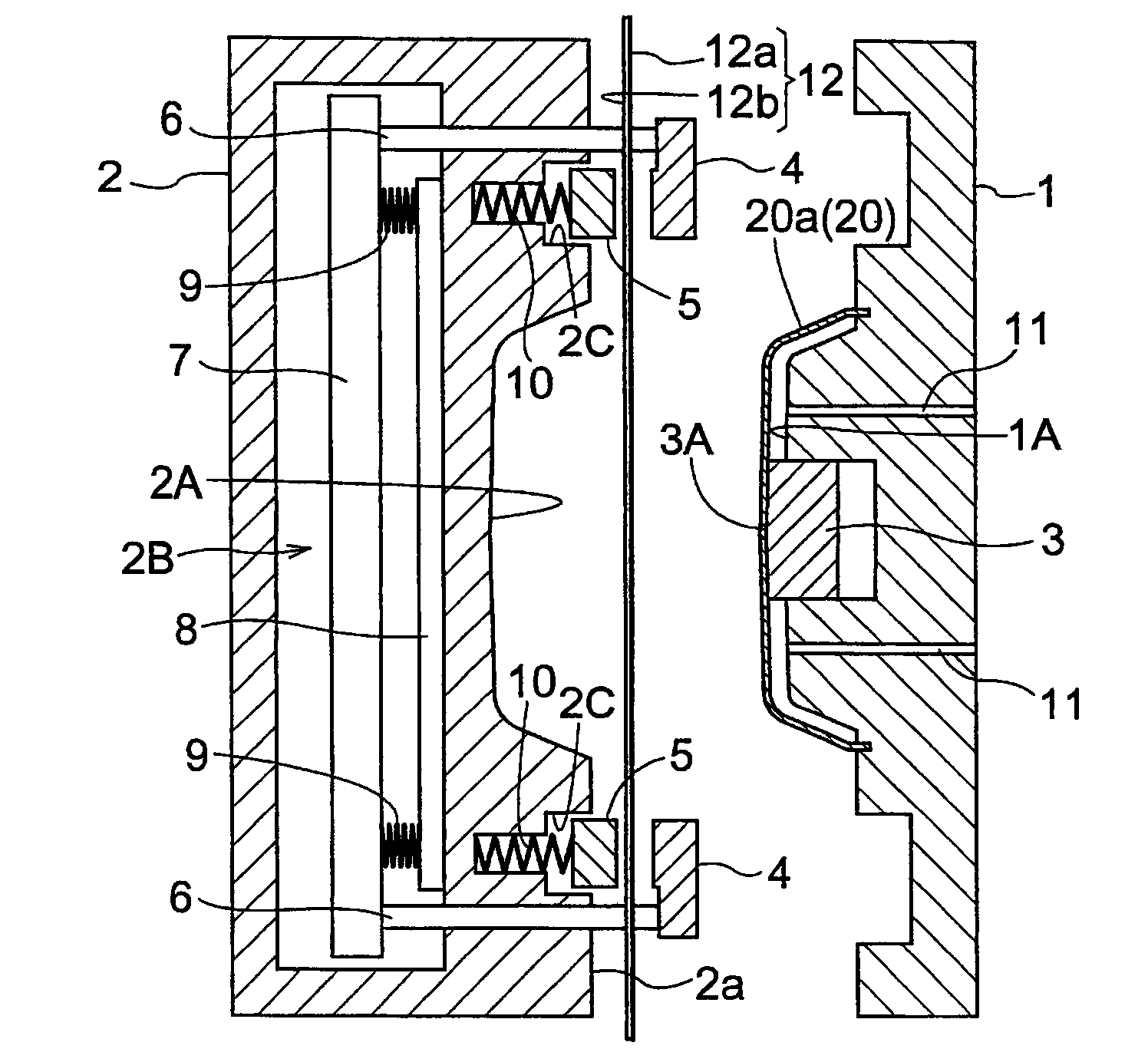

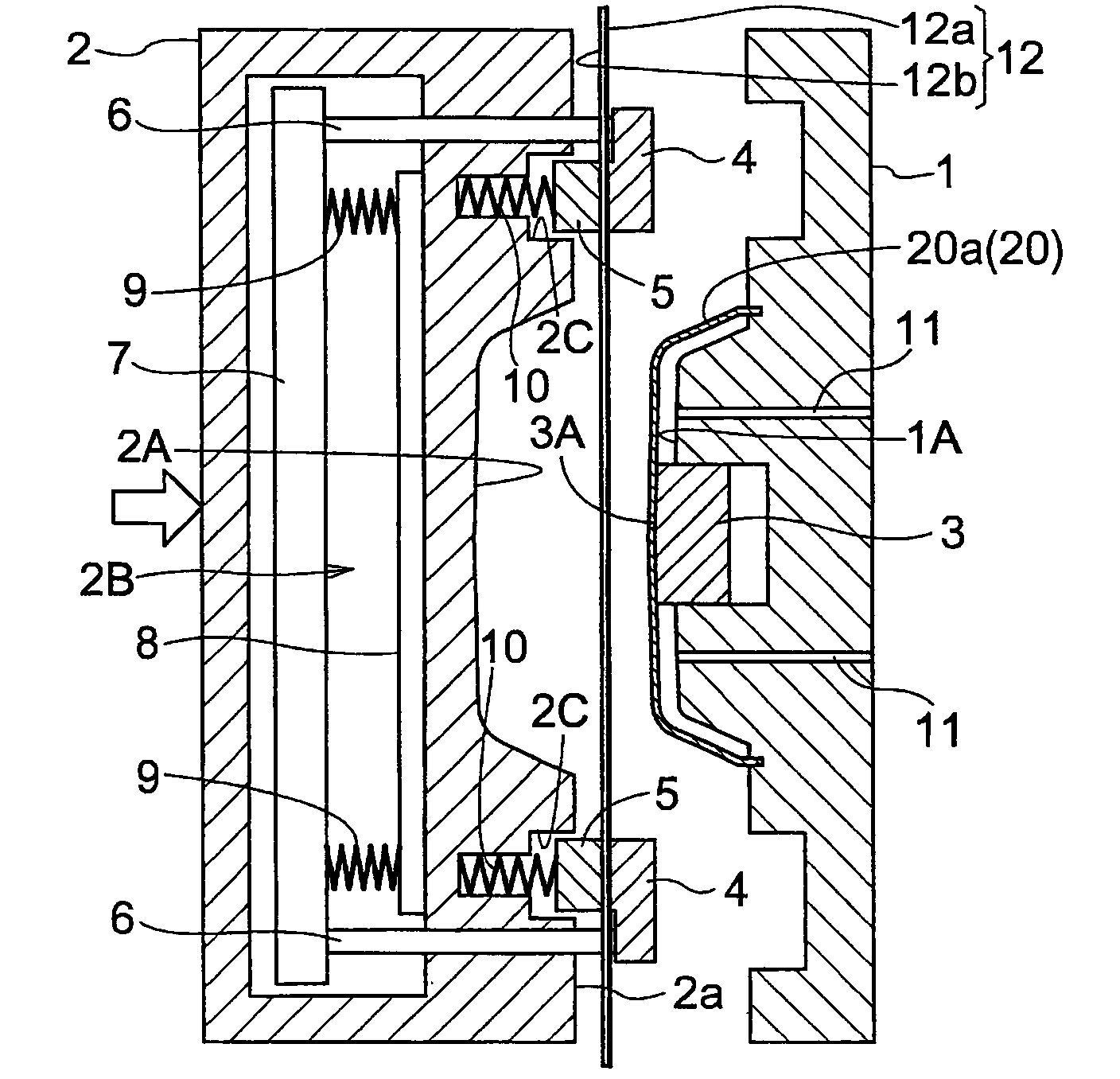

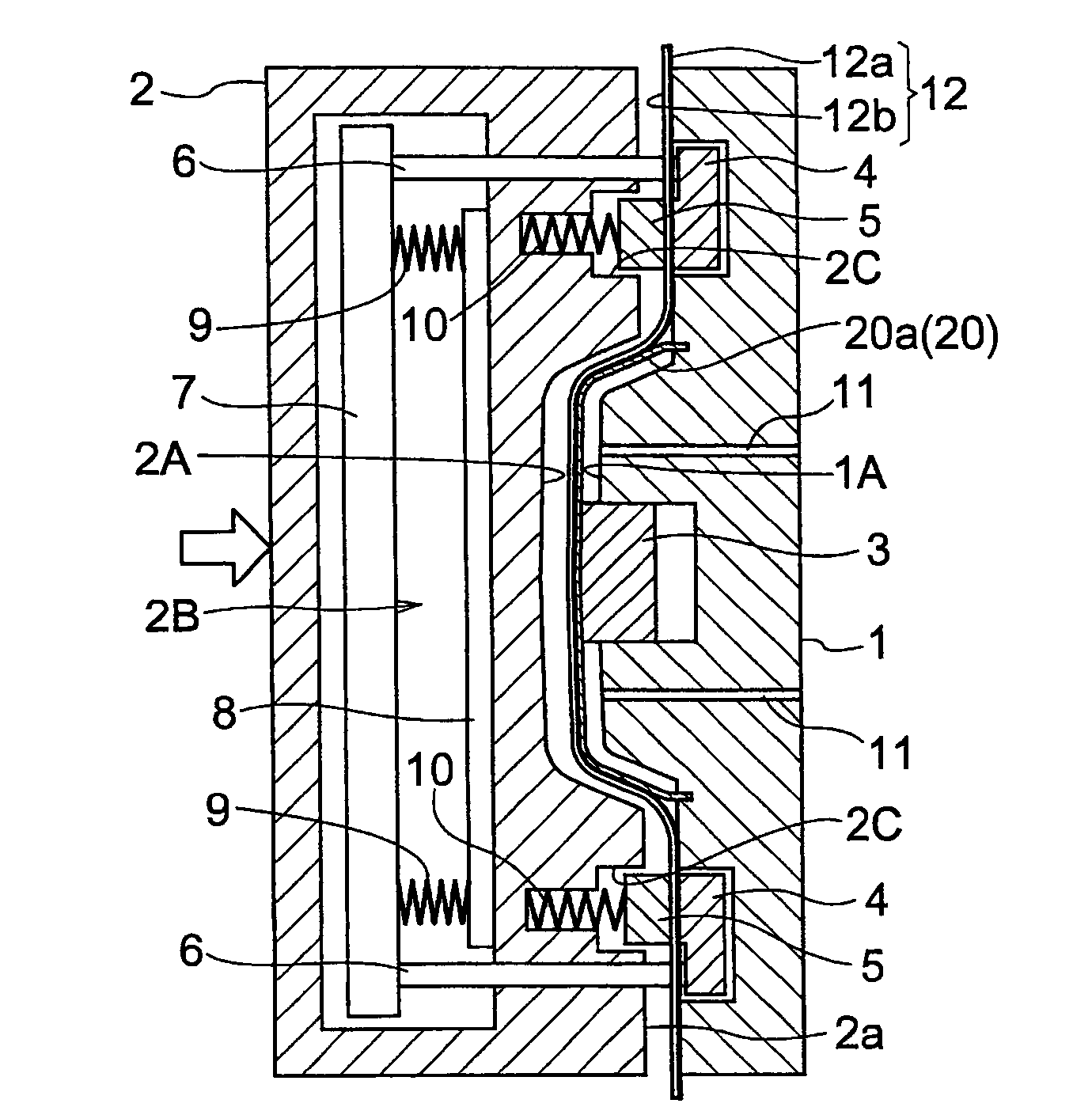

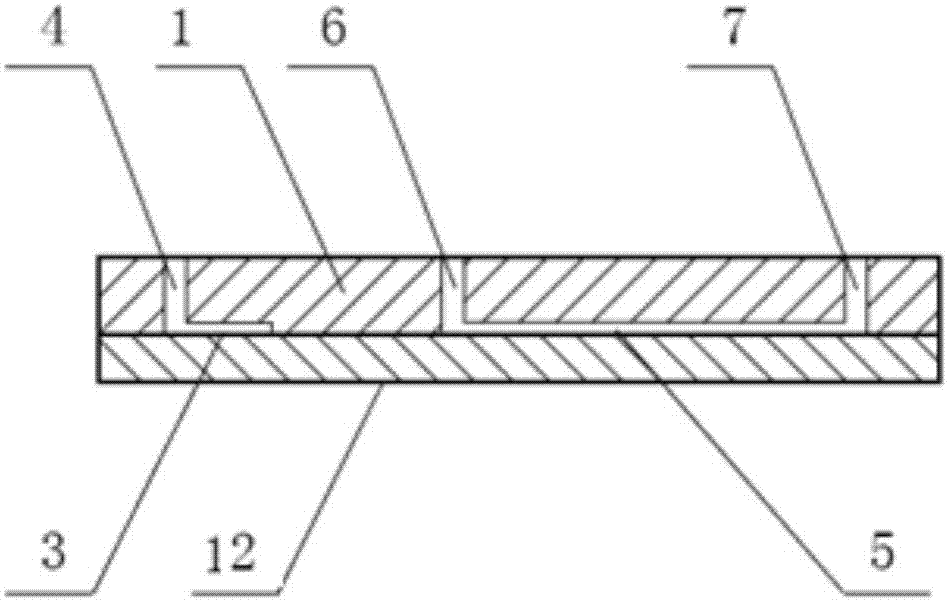

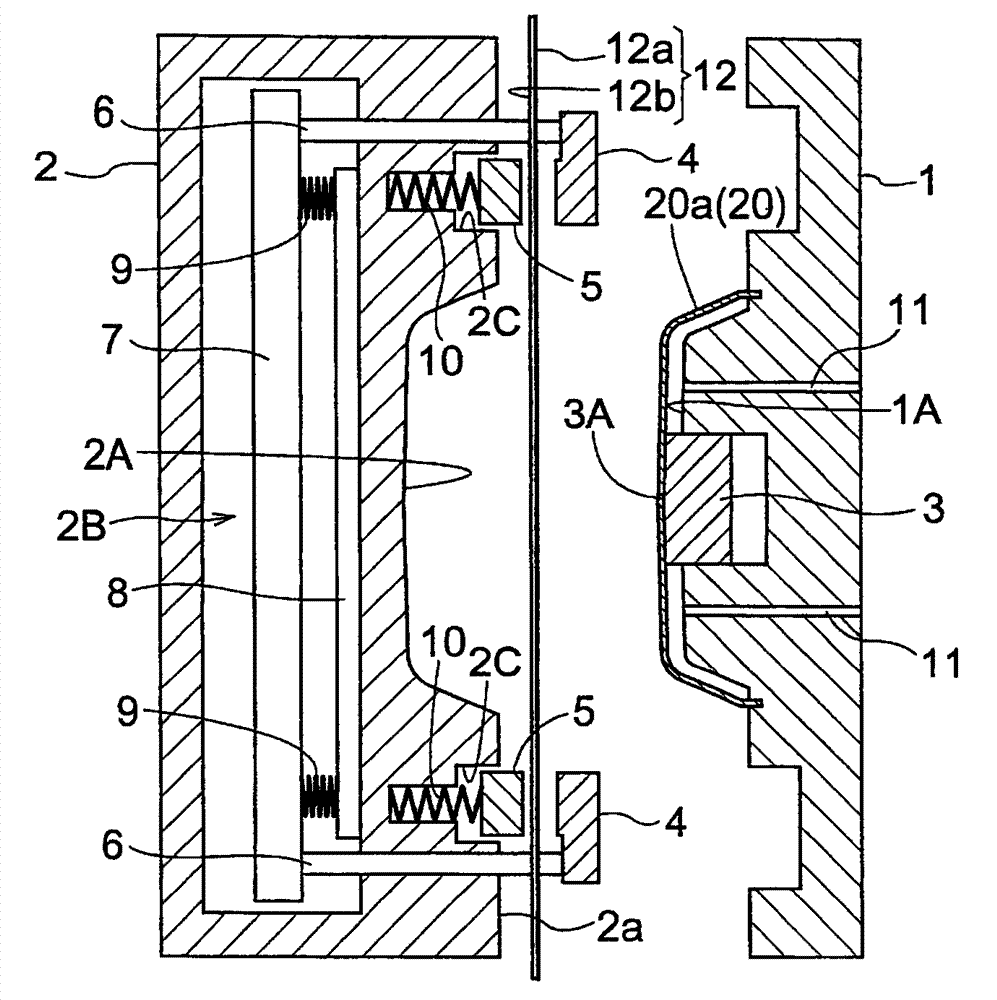

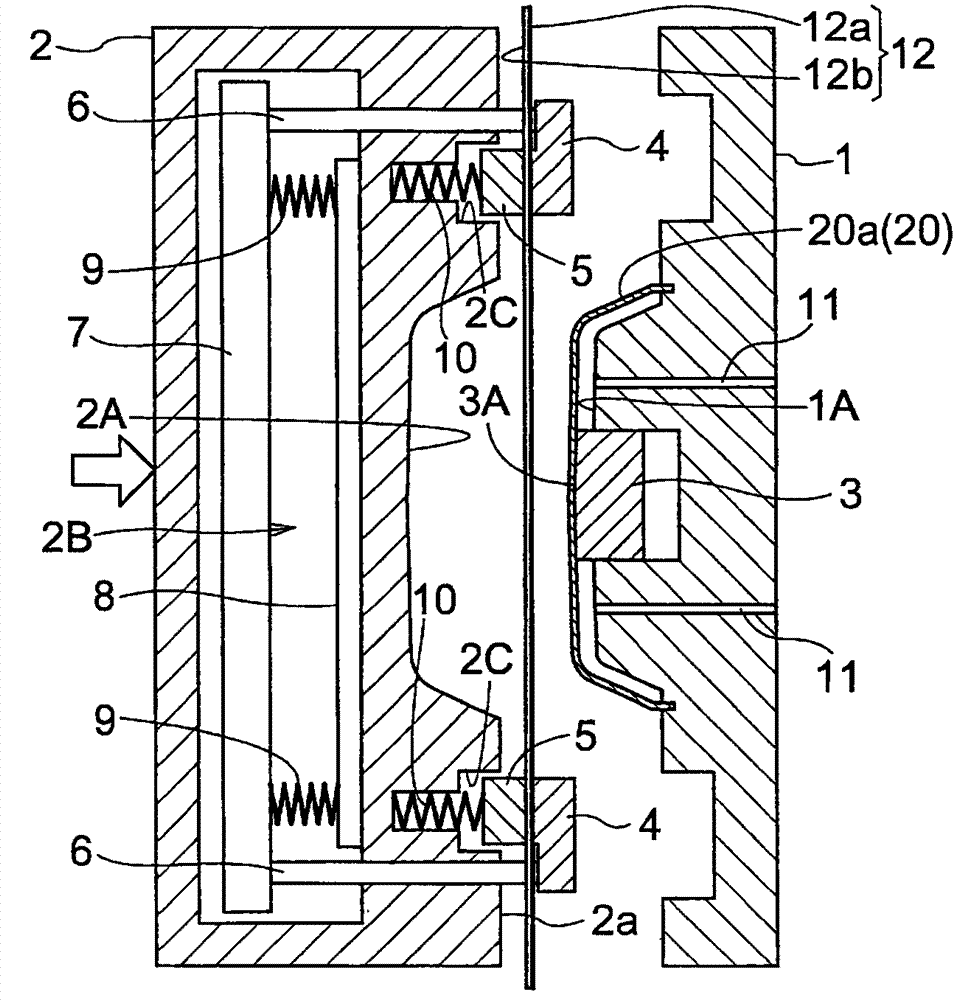

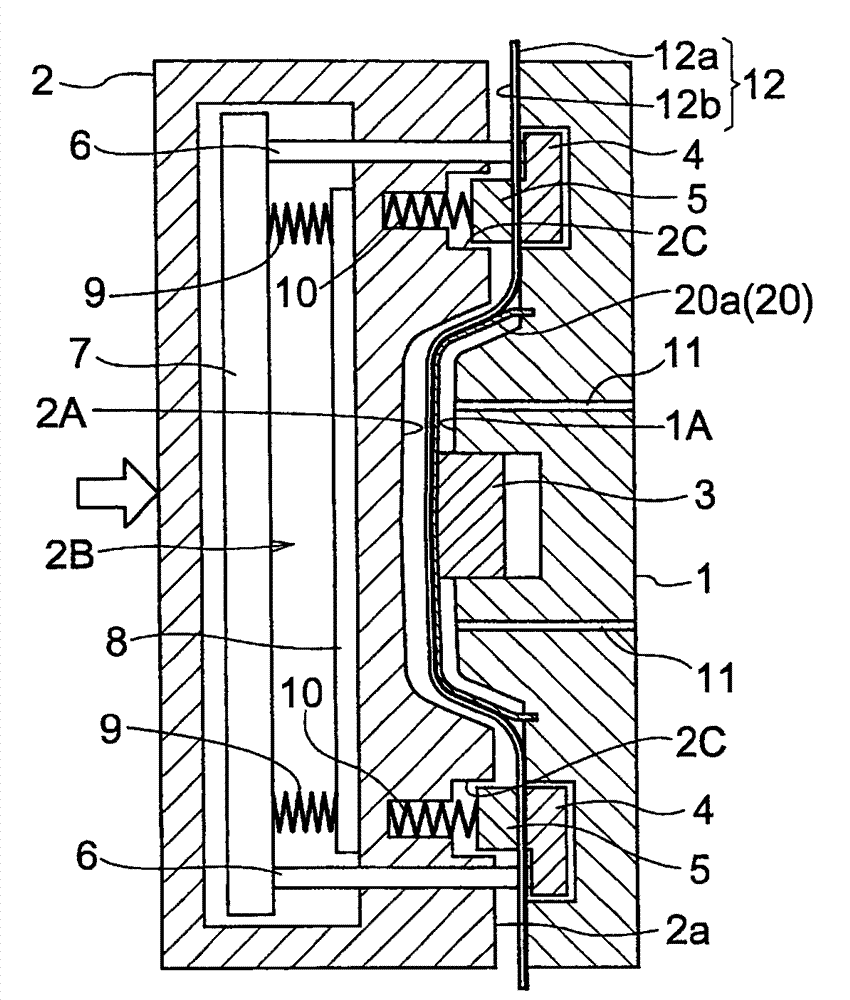

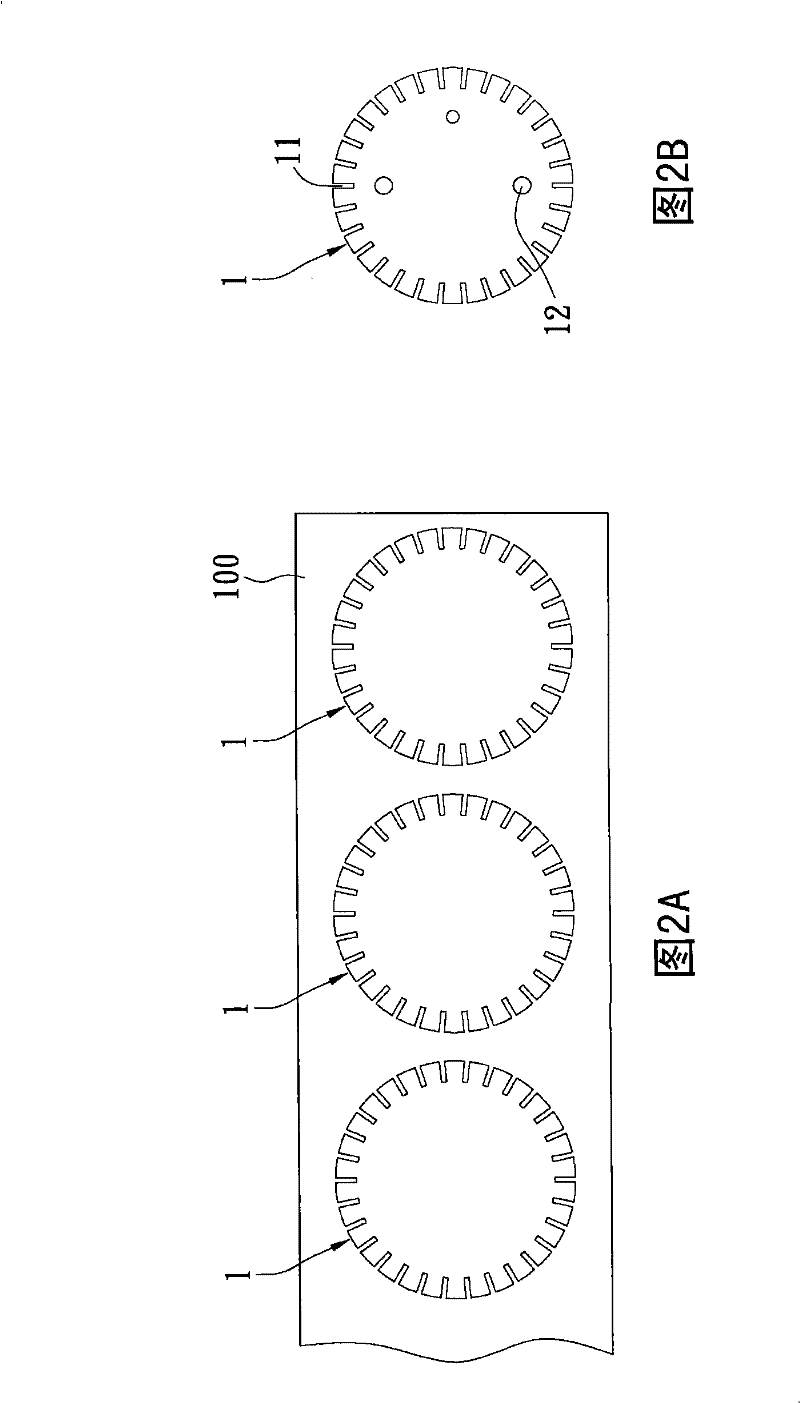

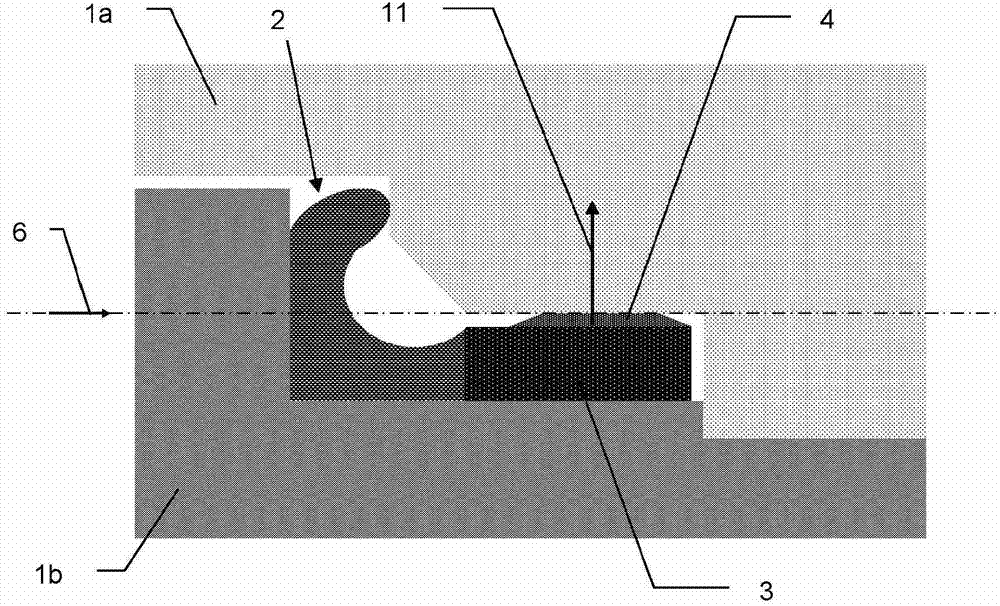

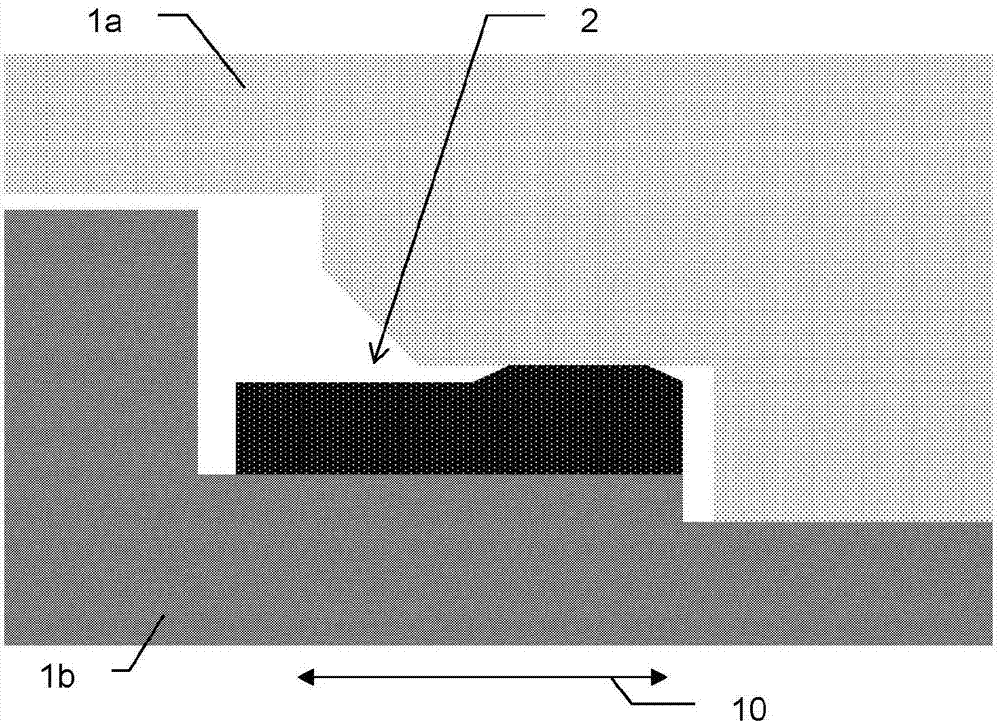

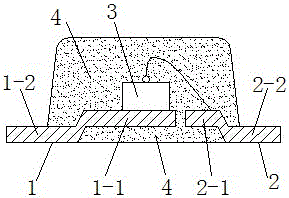

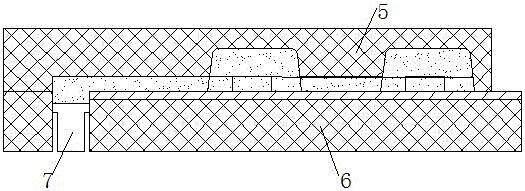

Mould used for injection molding and manufacture method for composite article

ActiveCN102069565ASimplify the manufacturing processRapid manufacturingCoatingsInjection mouldingInjection molding machine

The invention provides a mould used for injection molding and manufacture method for a composite article. In a mould used for injection molding used in manufacture of a composite article, the composite article forms a decorative layer on the surface of a metal body (20) provided with a protruding part (20a), and forms a resin part at the back side surface of the metal body (20), the mould used for injection molding is provided with: a first mould (1) is provided with a metal body (20); a second mould (2) and the first mould (1) are in spotting, a mould cavity used for injecting resins is formed between the first mould (1) and the metal body (20); and a decorative sheet keeping mechanism, before spotting of the first mould (1) and the second mould (2), disposes a transfer sheet (12) at a position, from which the transfer sheet gets away, of a molded surface of the second mould (2), and in the meantime that the transfer sheet (12) is pressed by and towards the protruding part (20a) of the metal body (20), makes the transfer sheet (12) be in a contact with the protruding part (20a) along the protruding part (20a).

Owner:NISSHA PRINTING COMPANY

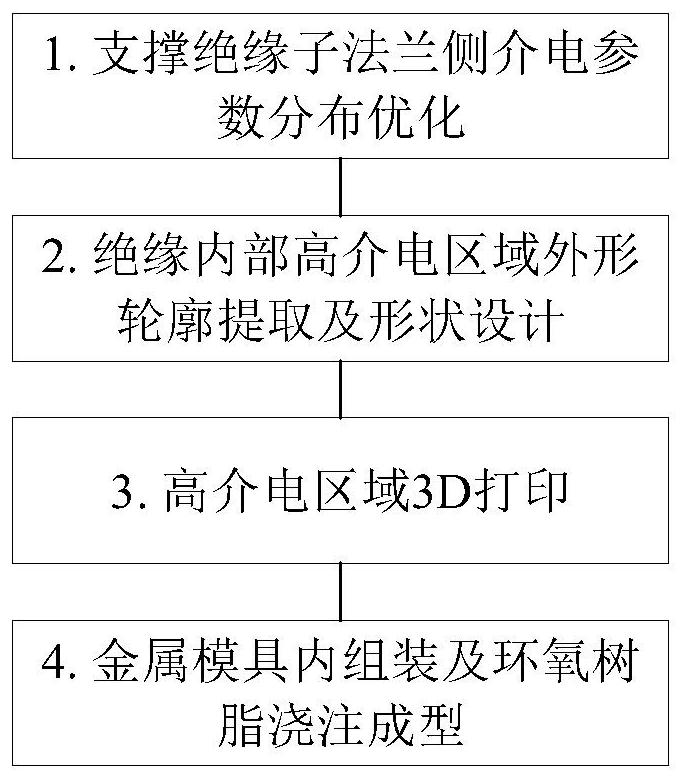

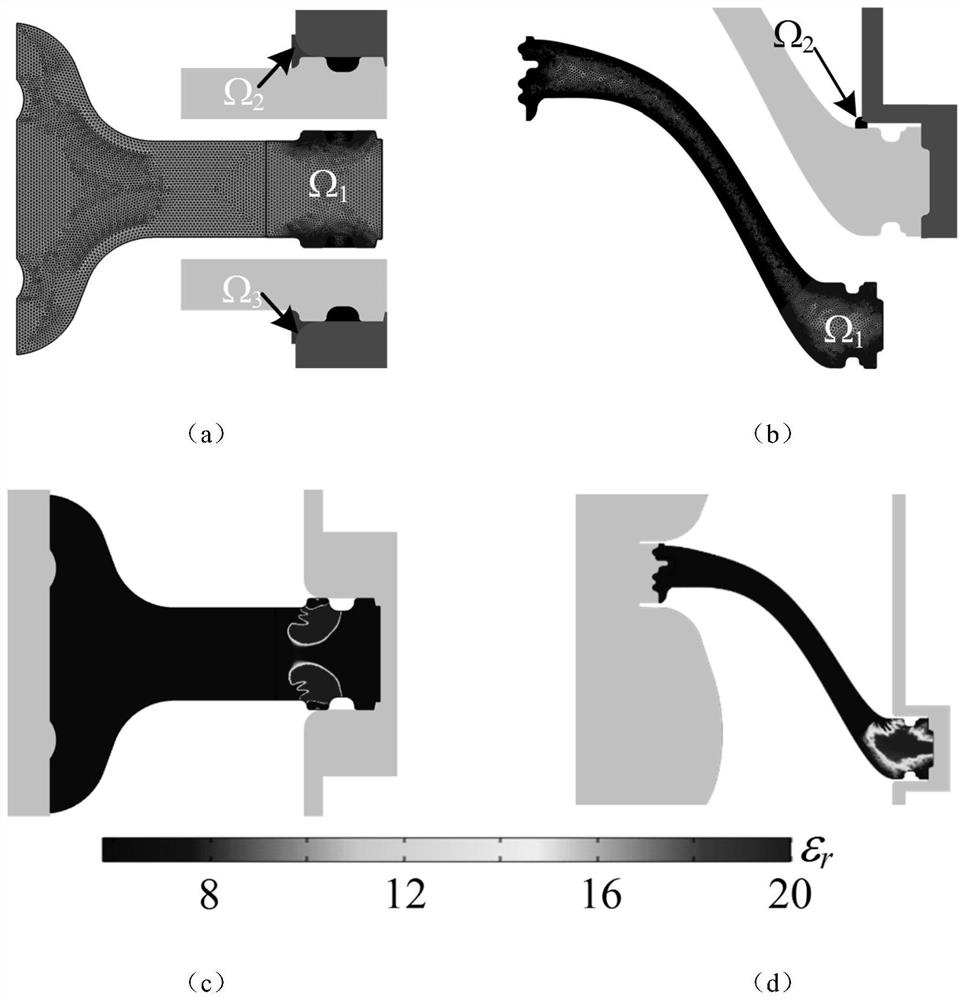

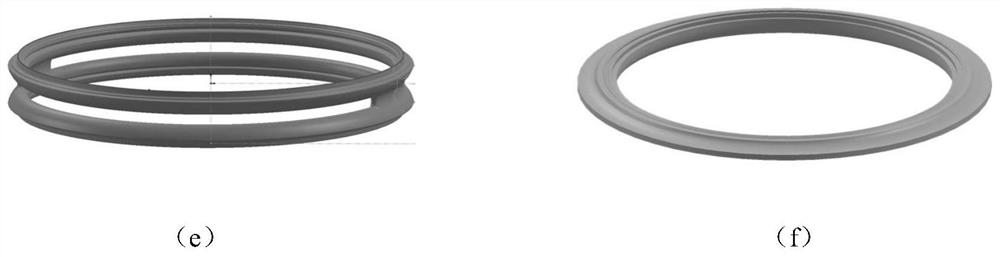

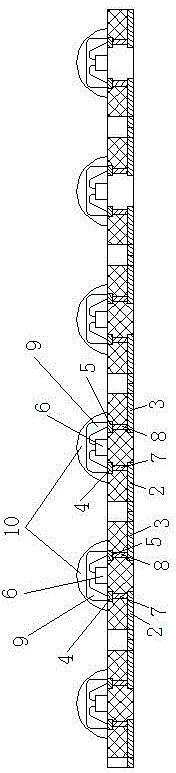

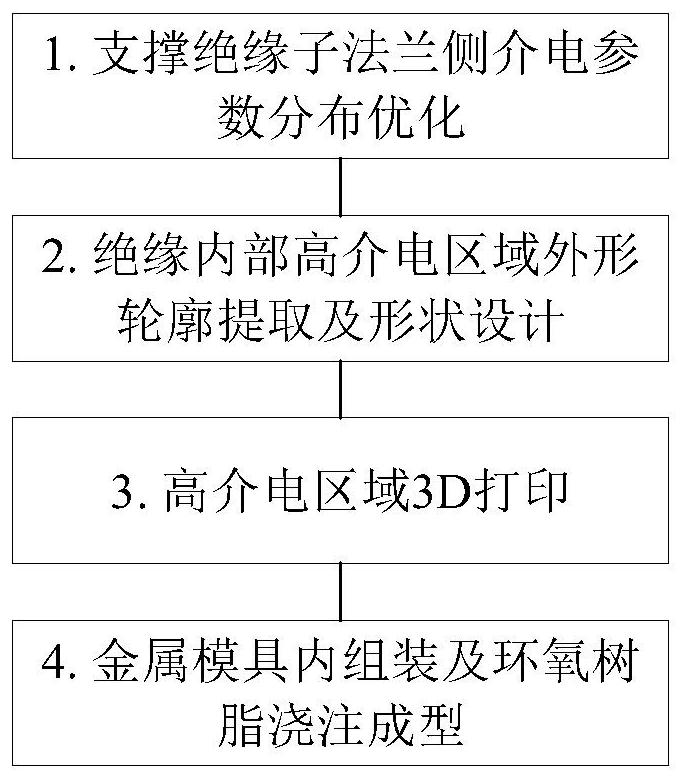

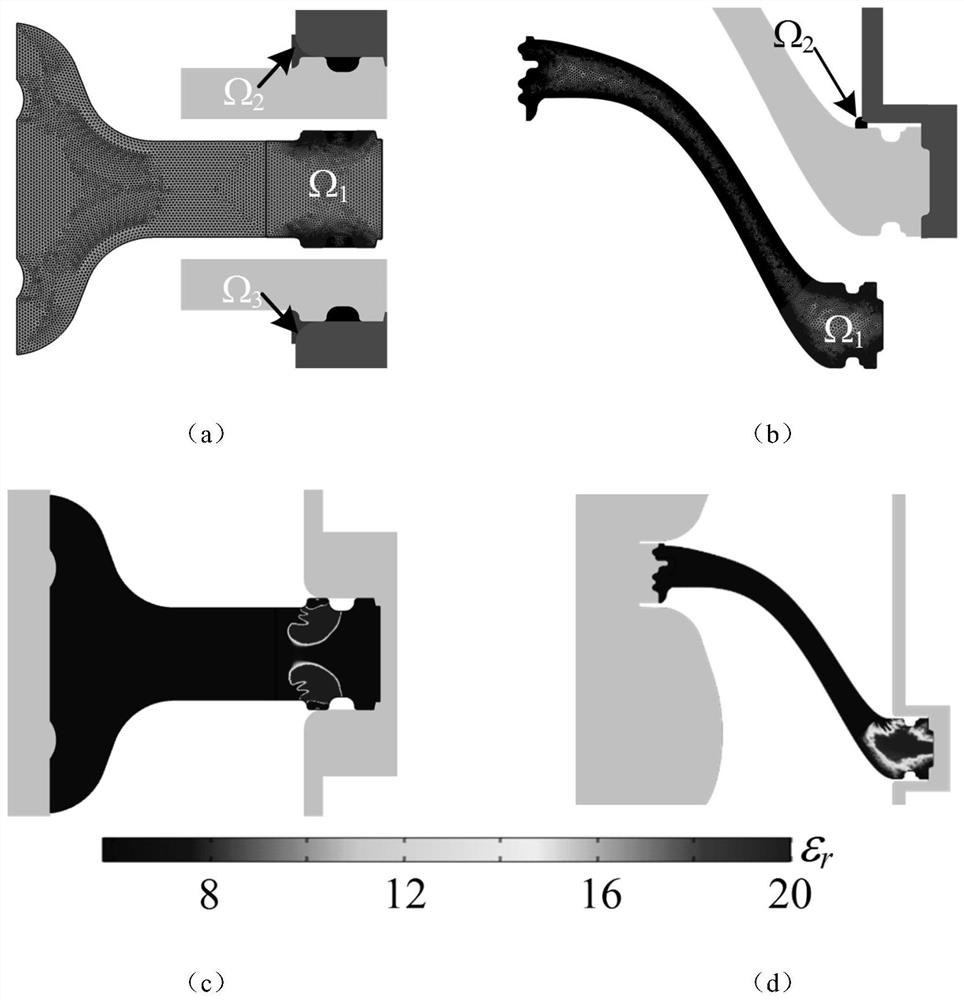

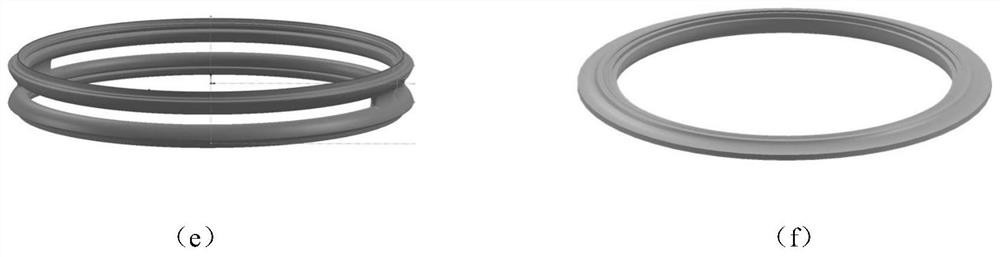

Suppression method for partial discharge at flange of GIS/GIL supporting insulator

ActiveCN113470907AHigh-precision manufacturingGood compatibilityImage enhancementAdditive manufacturing apparatusPhysicsPartial discharge

The invention discloses a suppression method for partial discharge at a flange of a GIS / GIL supporting insulator. According to the invention, reduction of electric field intensity in a flange-side local air gap area is taken as an optimization target, and optimal space distribution of flange-side insulation internal dielectric parameters of supporting insulator is solved by using a variable density or level set algorithm; and extracting the geometric contour of a high-dielectric region by using an image segmentation algorithm, and acquiring a CAD drawing of the geometric shape of the high-dielectric region through a parameter modeling mode. According to the invention, dielectric functional gradient material distribution is introduced in consideration of the mechanical properties and interface bonding strength of a cast workpiece, the structural design of a high-dielectric area workpiece is improved; a high-dielectric composite material is prepared in a high-dielectric filler / polymer blending mode, and manufacturing of the workpiece is completed through 3D printing; and finally, the high-dielectric workpiece is put into a traditional epoxy pouring metal mold, and thermocuring epoxy resin is poured to complete manufacturing of the supporting insulator.

Owner:XI AN JIAOTONG UNIV

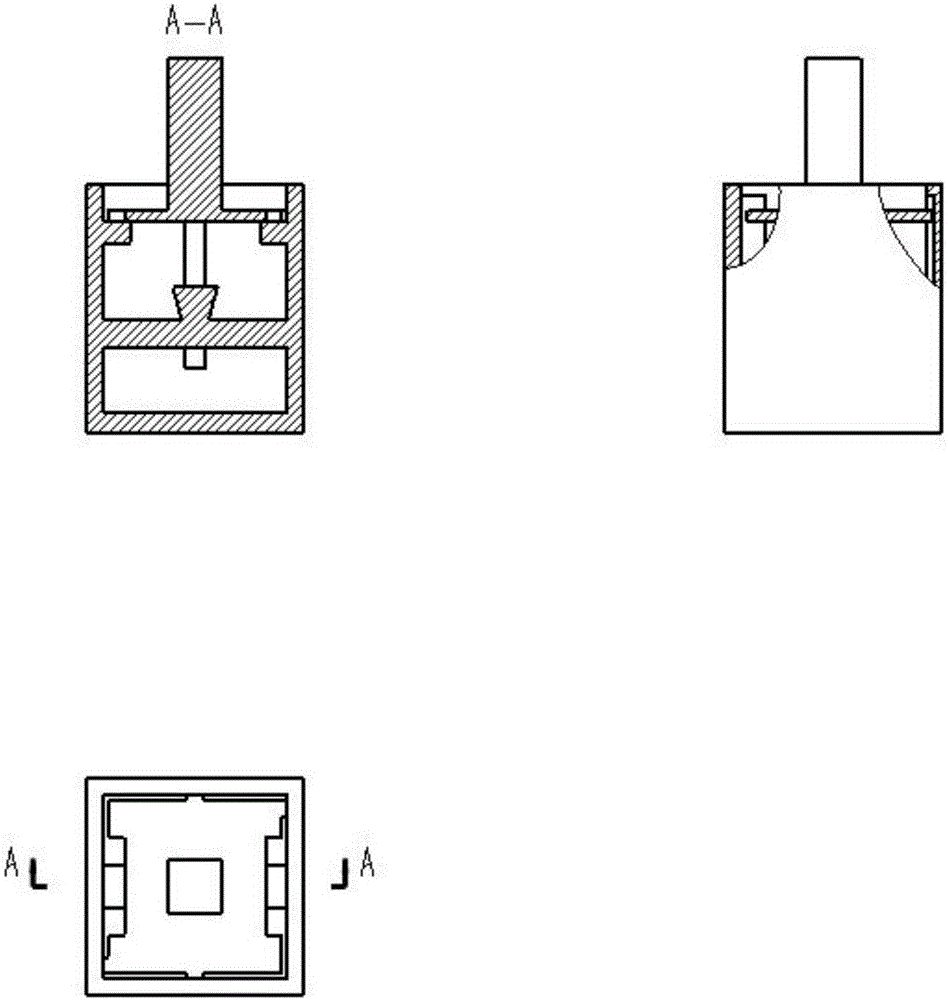

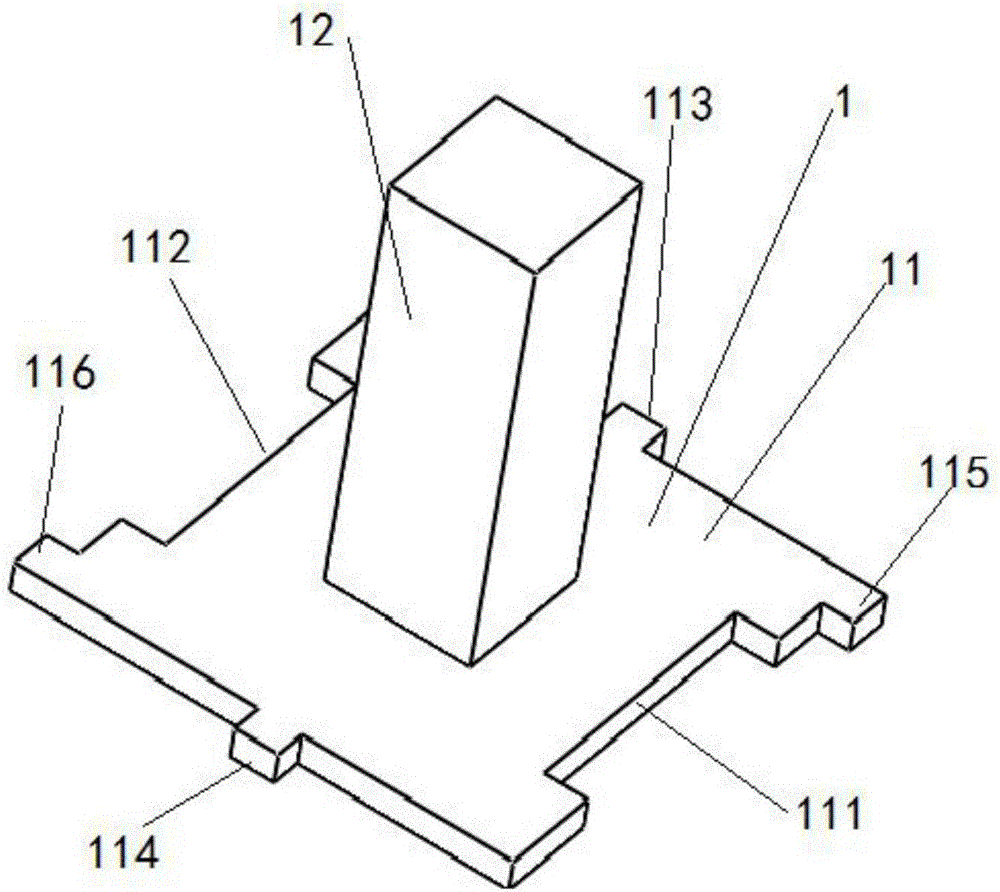

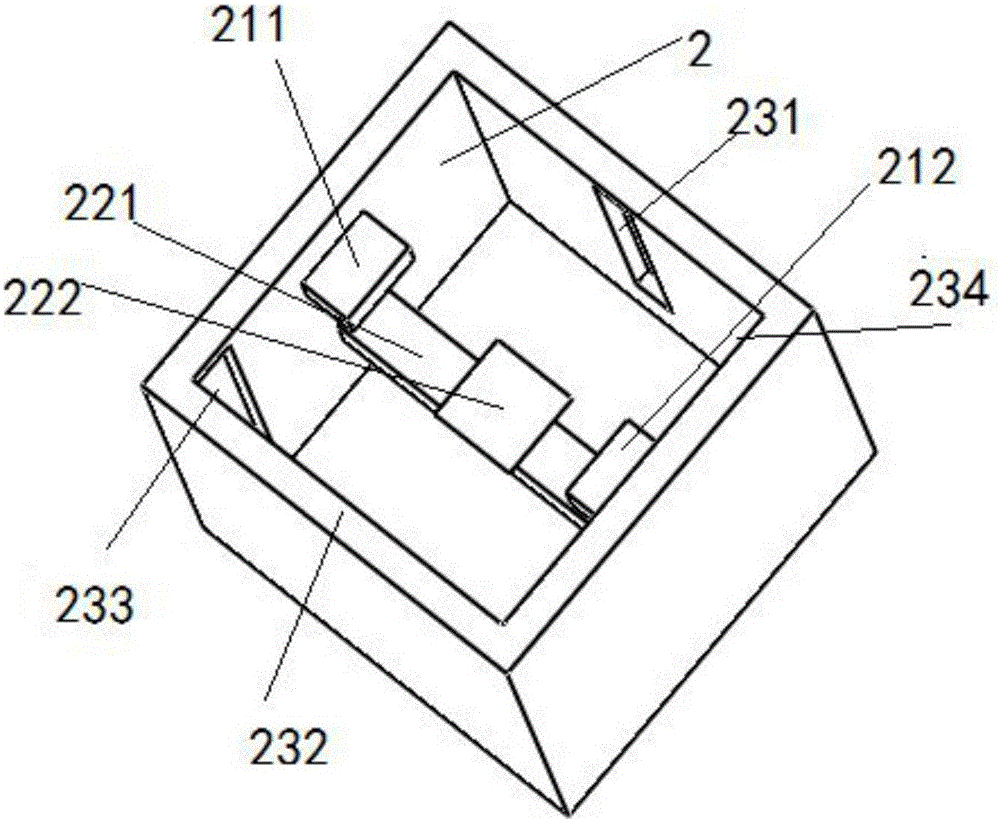

3D printing one-off two-stage pressure sensor

ActiveCN105784208ARapid manufacturingGood portabilityForce measurement by permanent gauge deformationForce measurement by elastic gauge deformationCross overEngineering

The invention discloses a 3D printing one-off two-stage pressure sensor, which comprises a first part and a second part, wherein the first part comprises a first thin plate layer and a vertical stressed boss located in the center; the second part has a hollow rectangular box body structure; the box body internally comprises a first boss and a second boss extending horizontally, a crossbeam, and an inverted cone boss; the first boss and the second boss are distributed at two opposite sides of the box body in an axial symmetry mode; the crossbeam is located right below the first boss and the second boss and crosses over two opposite sides of the box body, and the inverted cone boss is located in the center of the crossbeam; and the first thin plate layer of the first part is located on the upper surface of the two horizontally-extending bosses of the second part and is contacted with the bosses. two-stage pressure detection can be realized, and the limitation that the original similar sensor can only detect one-stage pressure can be overcome; 3D printing integrated forming can be adopted, and quick manufacturing is realized; no electronic device is used, and the price can be reduced to a large degree; and the portability is strong.

Owner:XIDIAN UNIV

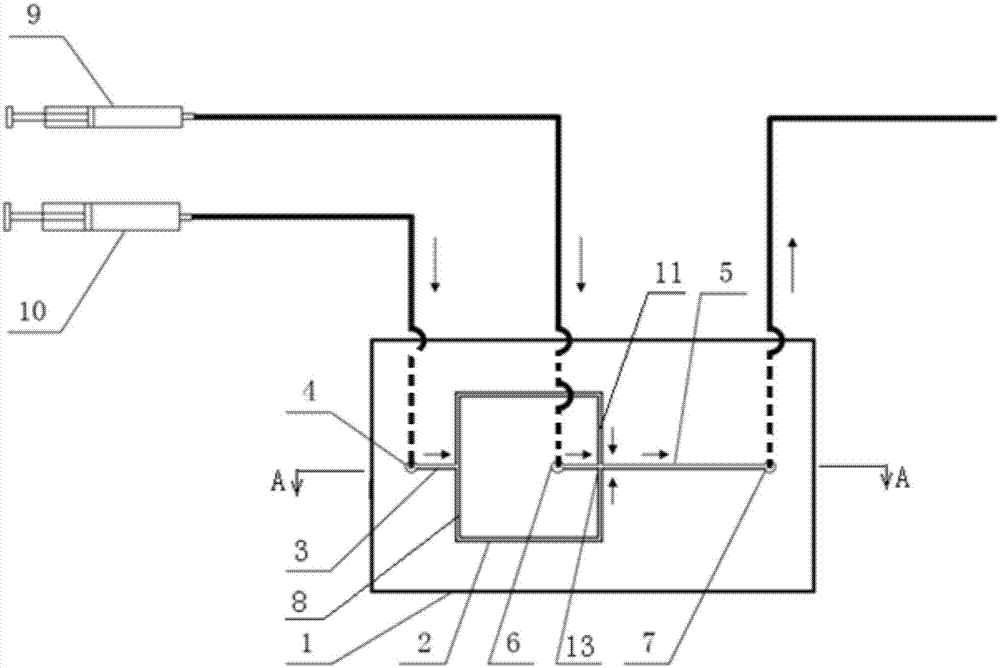

Micro-droplets for cell-free protein synthesis and preparation method thereof

ActiveCN107349882ARapid manufacturingUniform sizeSequential/parallel process reactionsFermentationOil phaseCell-free protein synthesis

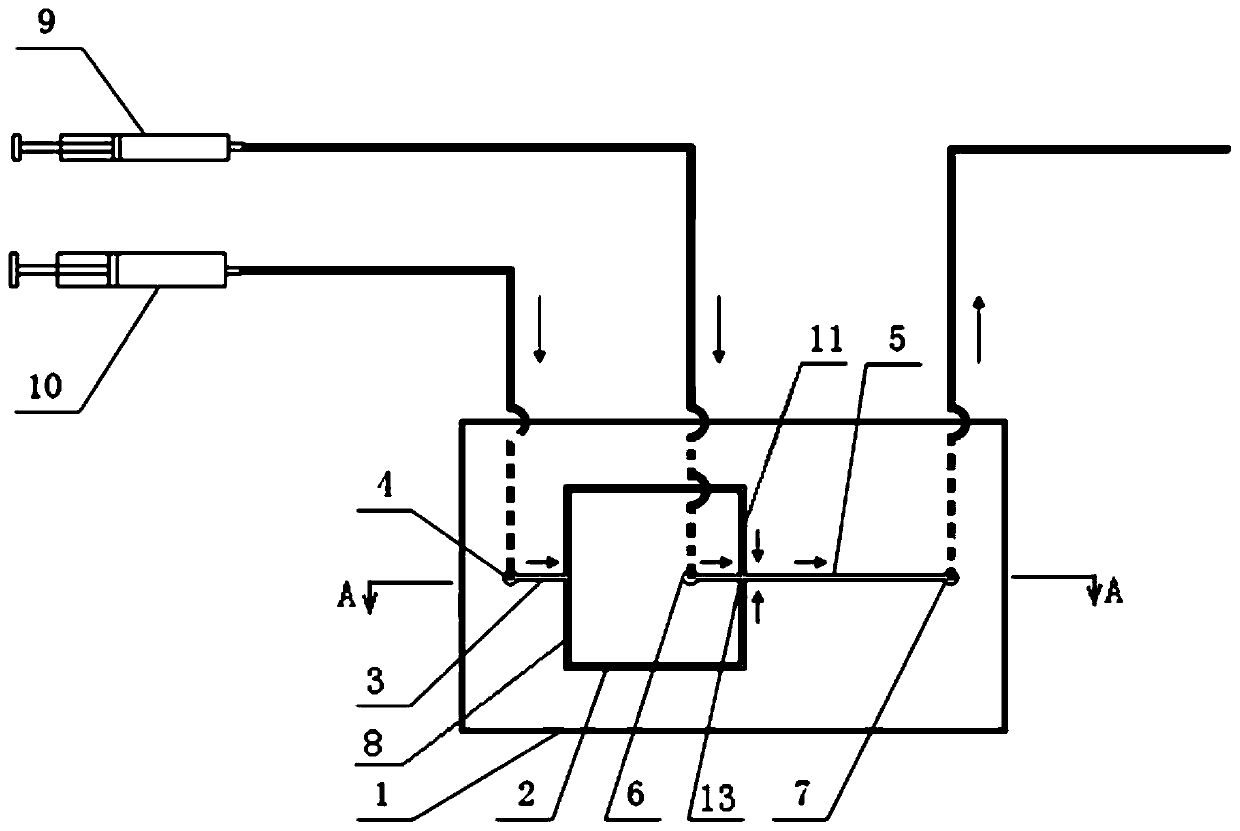

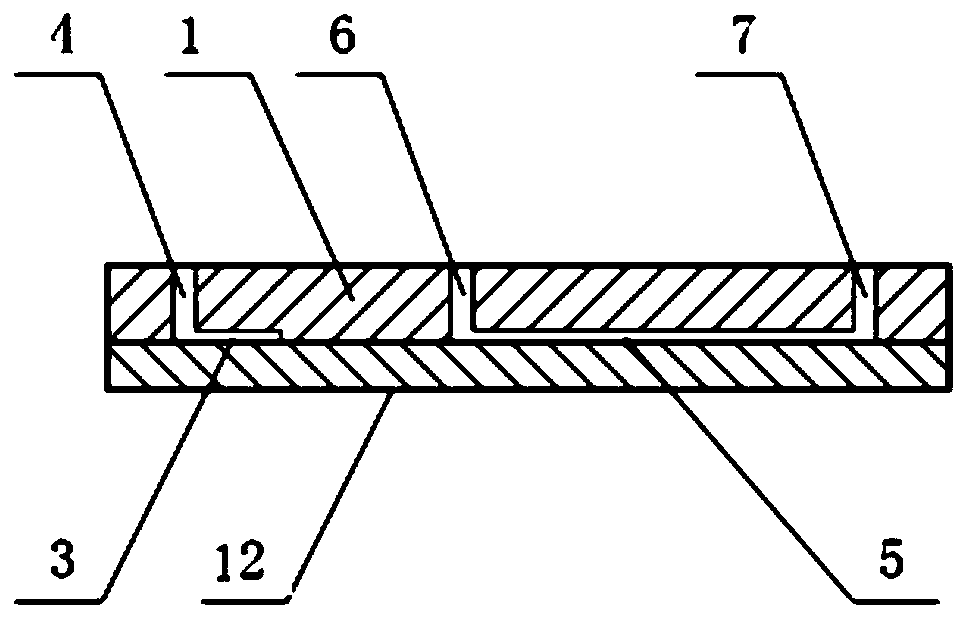

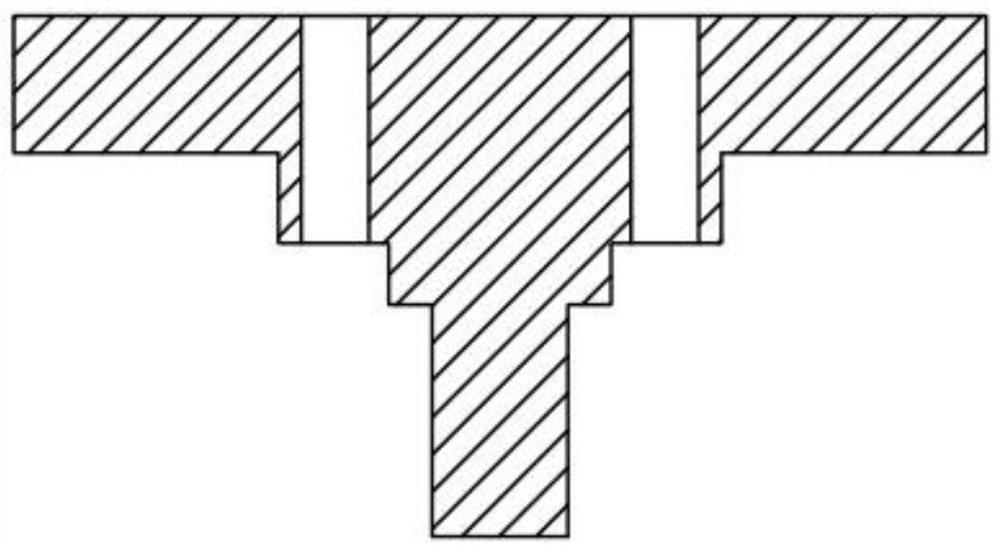

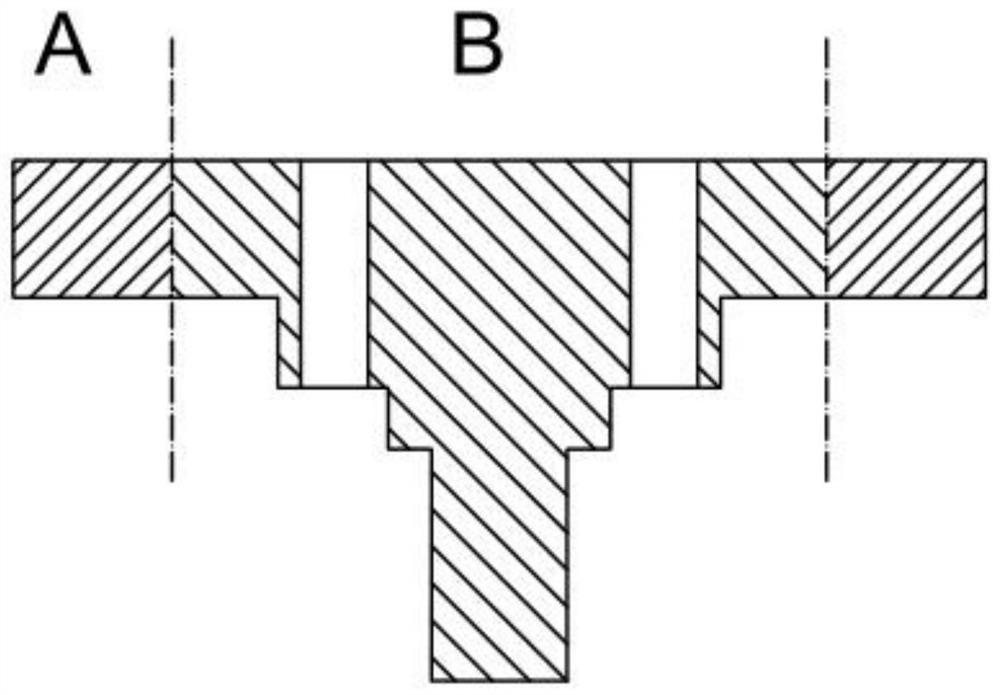

The invention discloses micro-droplets for cell-free protein synthesis and a preparation method thereof. The method includes the steps that firstly, a micro-fluidic chip device is used; 2, raw materials for protein synthesis are mixed to serve as a water phase, and the water phase is injected from a water phase inlet 6; an oil phase is injected from an oil phase inlet 4; in a cross channel 13, the water phase disperses under the shear force of the oil phase to form water-in-oil micro-droplets, and the micro-droplets are collected from a micro-droplet outlet 7 and then put into a thermostatic reaction vessel. According to the method, the micro-droplets can be rapidly prepared through the micro-fluidic chip device, and the obtained micro-droplets are uniform in size and stable in structure, and can provide a site for in-vitro protein synthesis; due to the unique microscale of the micro-droplets, part of the micro-droplets are used for simulating a cell environment so that a protein synthesis system working in the cell environment originally can obtain a similar environment, which facilitates the work of the protein synthesis system. Protein synthesis can be quantified, and the micro-droplets can be applied to detection and diagnosis.

Owner:TIANJIN UNIV

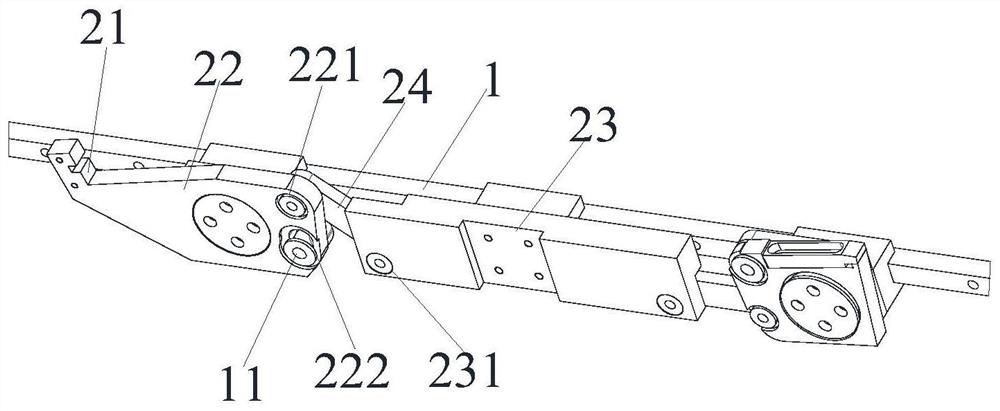

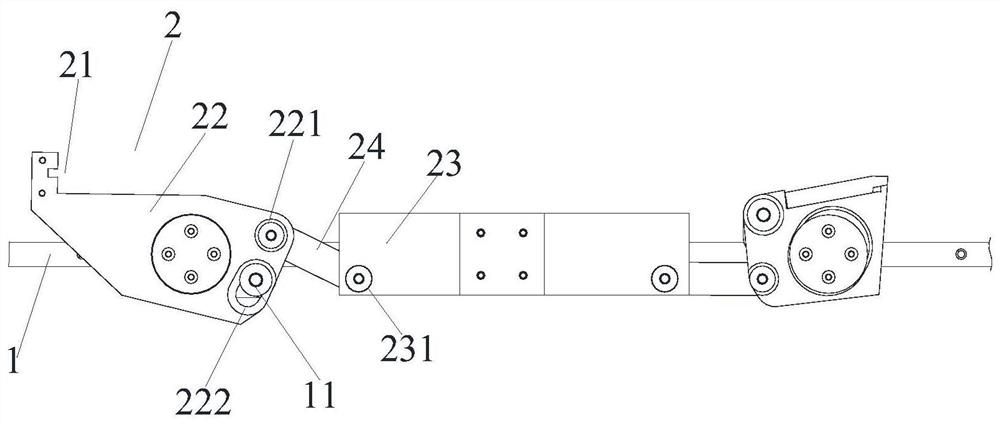

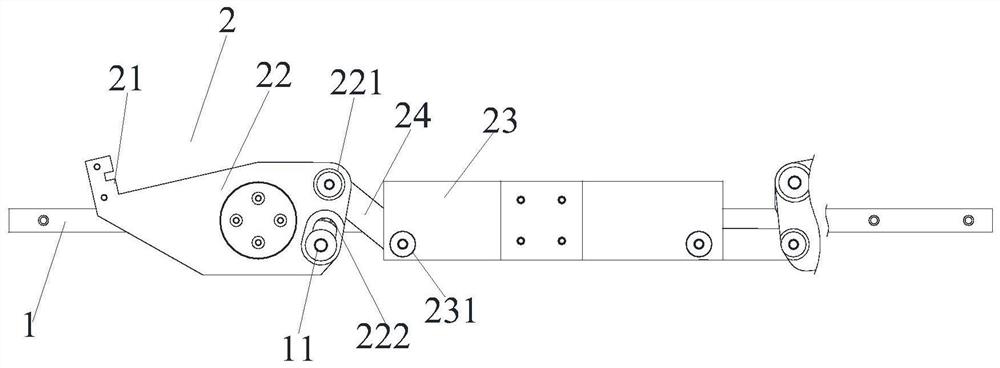

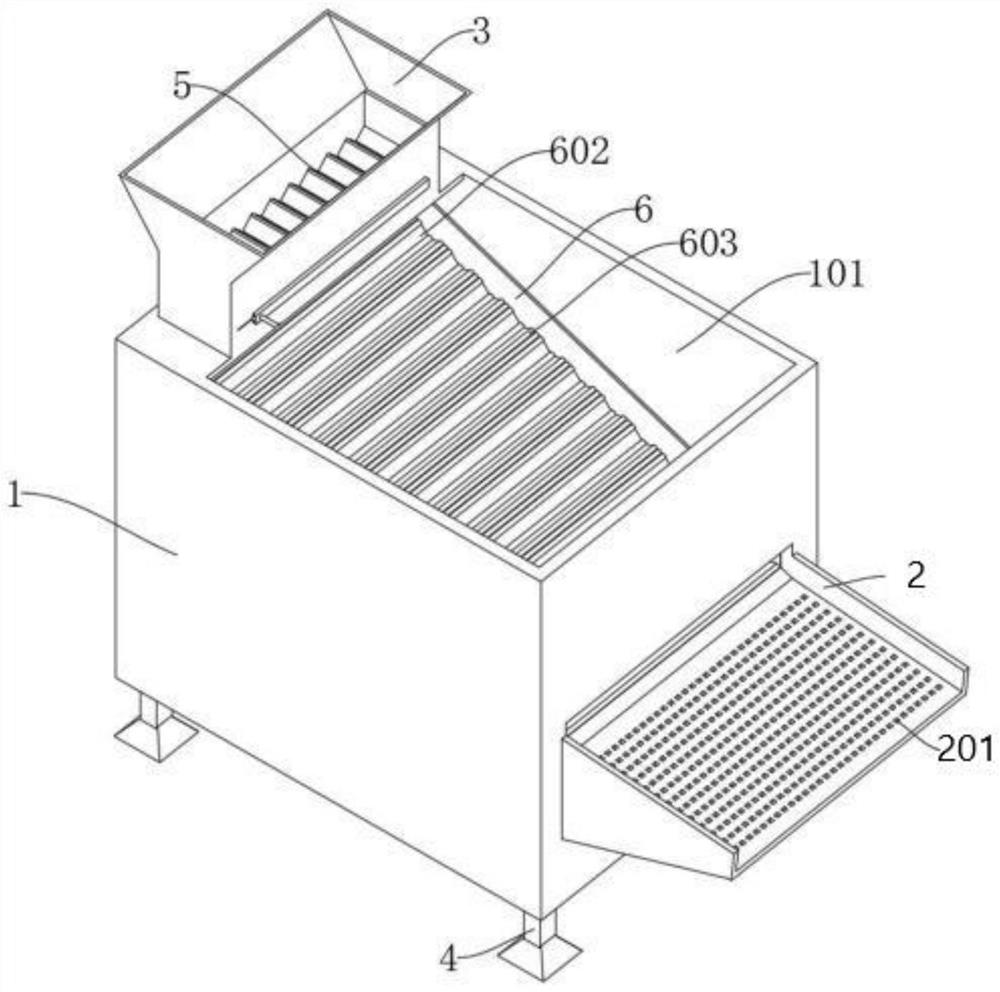

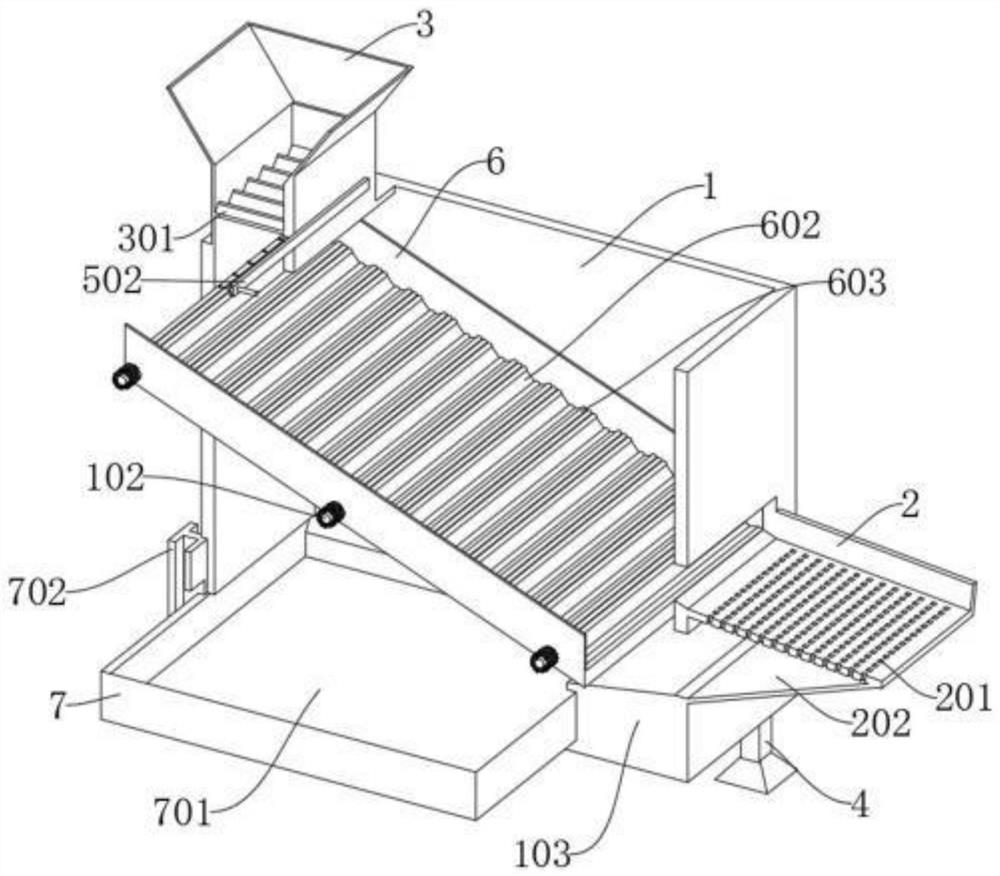

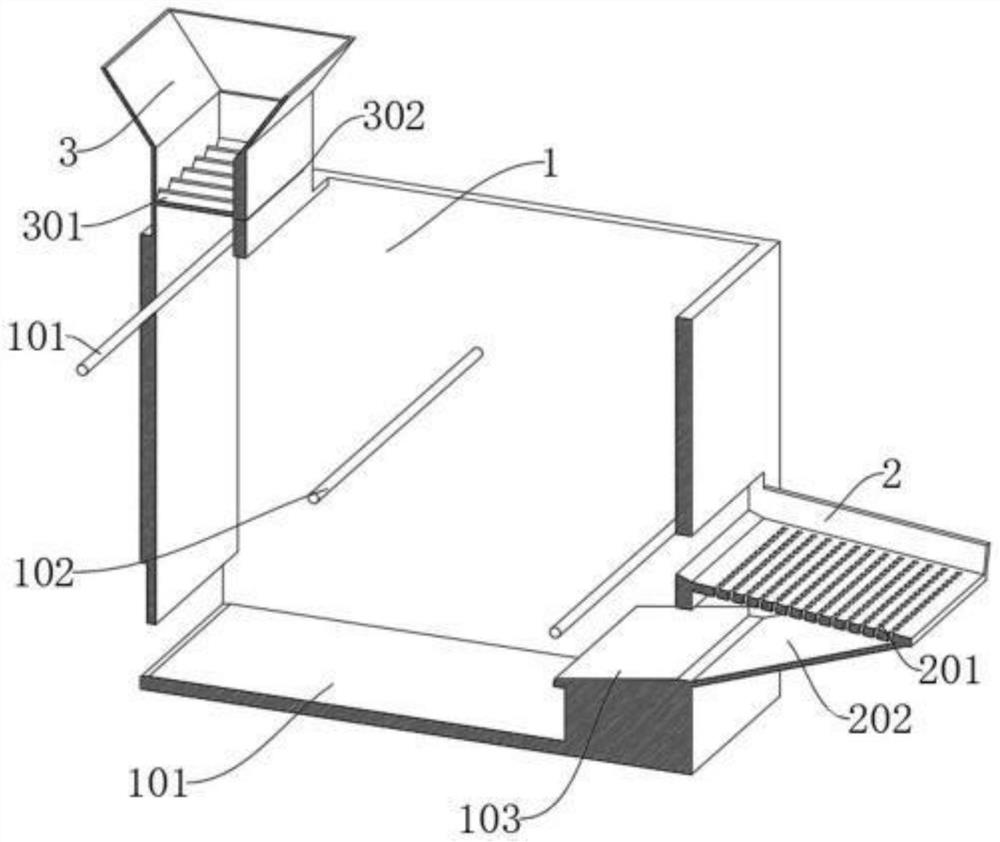

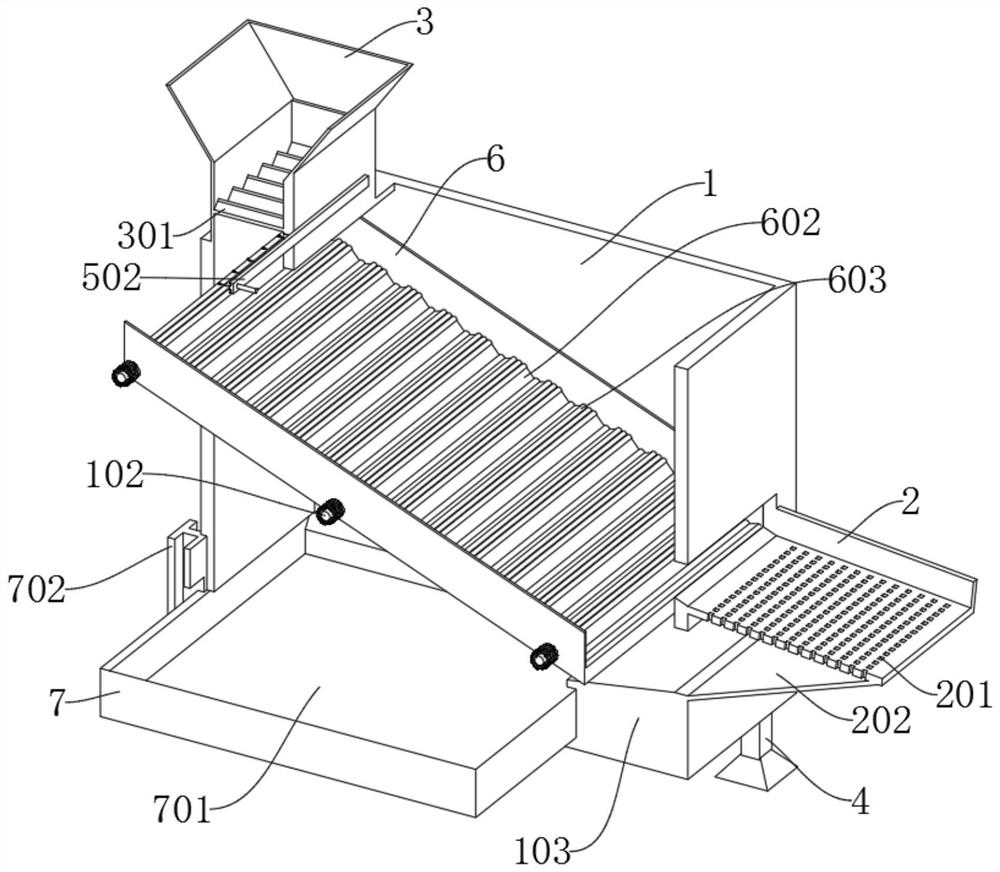

Book pushing structure

PendingCN111874604ARealize push again and againRapid manufacturingConveyor partsMechanical engineeringIndustrial engineering

The invention discloses a book pushing structure which comprises a fixing plate and a book pushing assembly. The book pushing assembly is movably connected with the fixing plate, and after the book pushing assembly moves on the fixing plate, ascending or descending of the book pushing assembly is achieved. After the book pushing assembly moves on the fixing plate, a book can be pushed by ascendingof the book pushing assembly, after the book pushing assembly descends, the book pushing assembly can be folded in the fixing plate, in the reciprocating ascending and descending operation, the bookcan be pushed time and time again, and after the book pushing assembly descends, a next book cannot be stopped from moving to the fixing plate, so that the book can be quickly produced and manufactured.

Owner:深圳市傲世杰机械设备有限公司

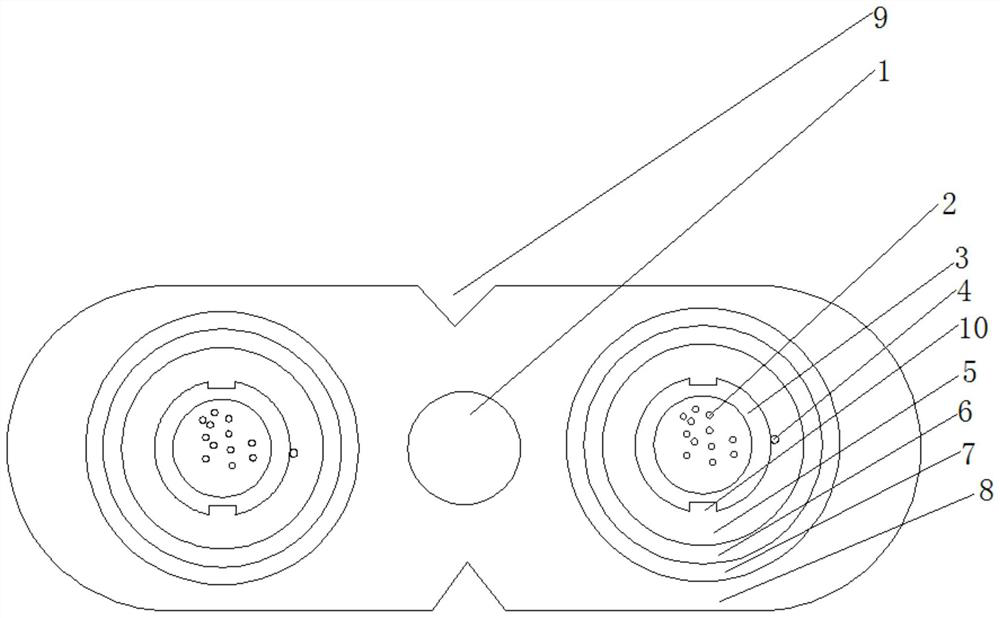

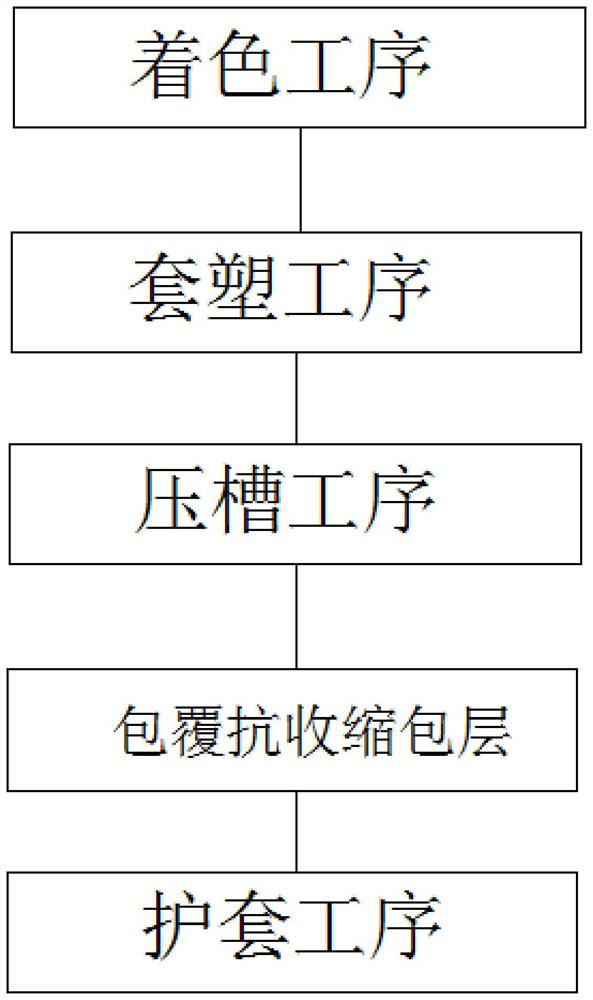

Anti-shrinkage multi-unit parallel beam tube optical cable and manufacturing method thereof

PendingCN112034571AIncrease duty cycleInhibition of contractionFibre mechanical structuresBeam tubeEngineering

The invention discloses an anti-shrinkage multi-unit parallel beam tube optical cable and a manufacturing method thereof. The optical cable comprises a cable core and a sheath layer wrapping the cablecore, the cable core comprises a center reinforcing part, at least two parallel beam tubes and an anti-shrinkage wrapping layer, and the multiple beam tubes are arranged around the center reinforcingpart and are parallel to the center reinforcing part; and each beam tube comprises an optical fiber unit and a loose tube wrapping the optical fiber unit, the outer surface of the loose tube is provided with a plurality of grooves, the plurality of grooves are arranged at intervals along the axial extension direction of the loose tube, an anti-shrinkage wrapping layer wraps each loose tube, and part of each anti-shrinkage wrapping layer is embedded into the grooves. The manufacturing method comprises a plastic coating process, a groove pressing process, an anti-shrinkage wrapping layer coating process and a sheath process. The optical cable is compact in structure, light in weight and high in optical fiber duty ratio, and the shrinkage problem of the beam tubes in the optical cable is solved; According to the manufacturing method, the optical cable can be rapidly and conveniently produced and manufactured, and the structural requirements of the optical cable are met.

Owner:宏安集团有限公司

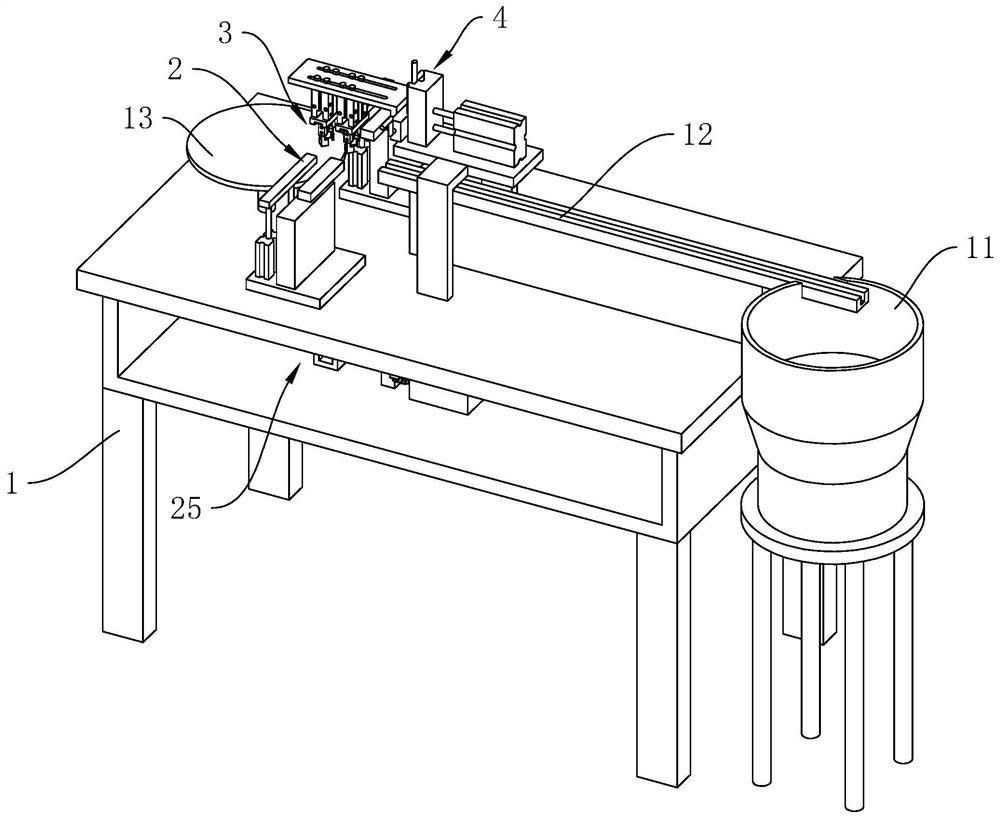

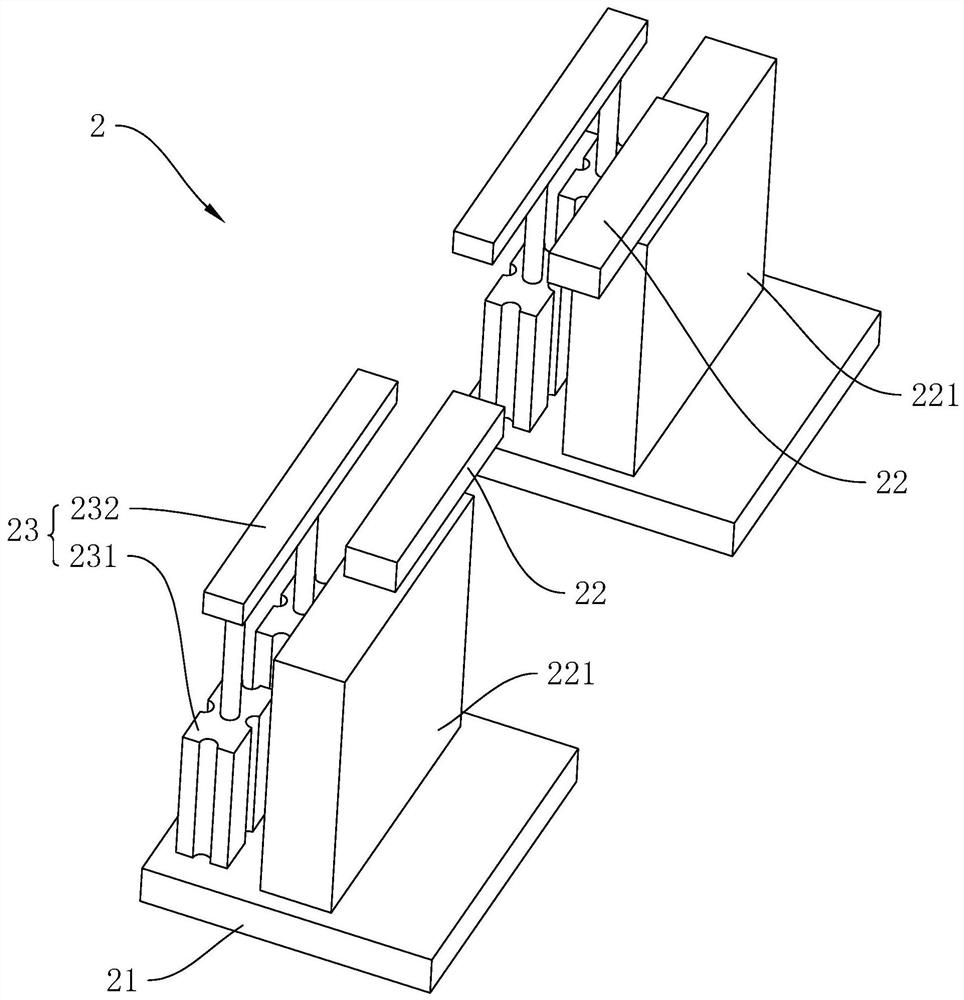

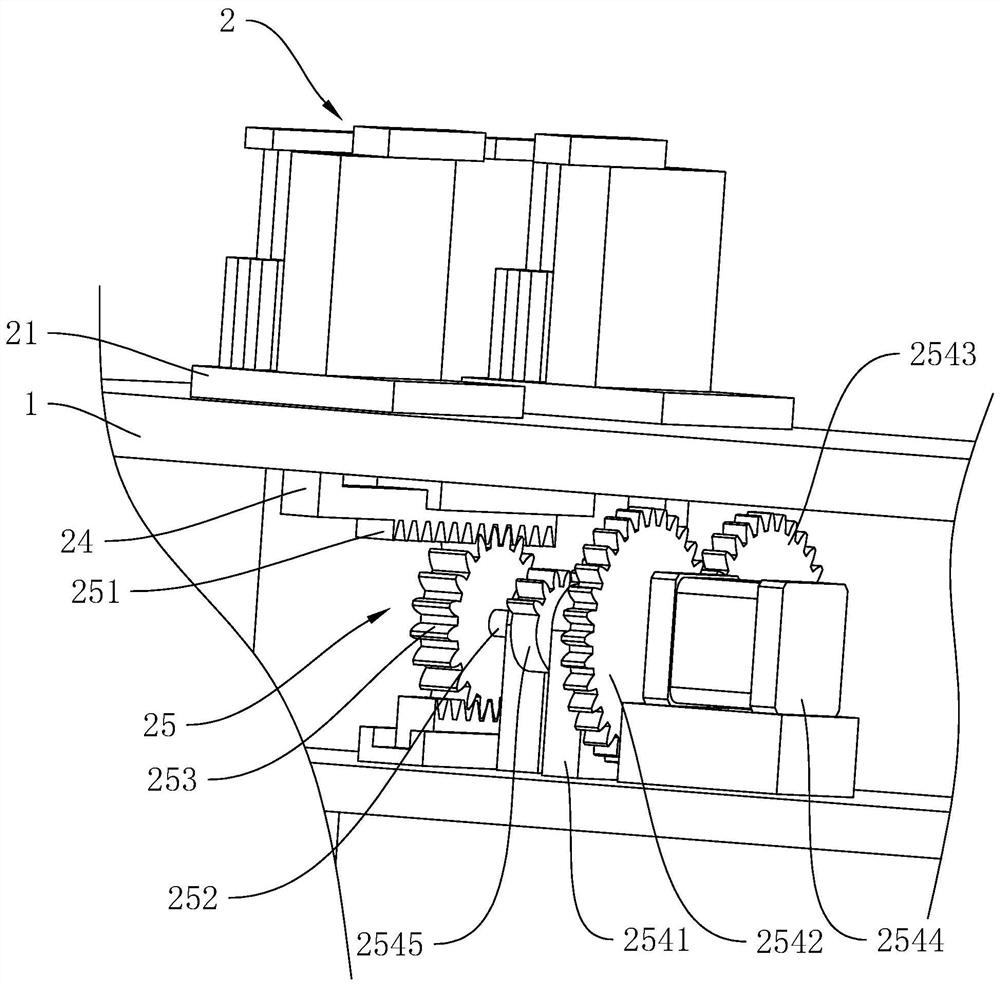

Automatic capacitor assembling device

ActiveCN112927933AImprove accuracyImprove stabilityElectrolytic capacitorsTerminal applying apparatusPhysicsEngineering

The invention relates to an automatic capacitor assembling device, which comprises a machine frame, an element vibration disc, an element conveying track and a station disc are arranged on the machine frame, the discharging end of the element conveying track faces the station disc, and the automatic capacitor assembling device is characterized in that: a clamping device is arranged at the position, between the element conveying track and the station disc, of the machine frame; the clamping device comprises two sliding plates, an element positioning clamping jaw, an element clamping assembly and a sliding plate driving assembly, the two sliding plates are slidably connected with the top face of the machine frame, the element positioning clamping jaw is fixed to the side, away from the machine frame, of each sliding plate, and the element clamping assembly is arranged on the sliding plates and located at the discharging end of the element positioning clamping jaw, the sliding plate driving assembly is arranged in the machine frame, and the machine frame is provided with a batch feeding device above the element conveying track. According to the invention, the assembly accuracy of the element and the colloidal particles can be effectively improved, the subsequent assembly of the element is further ensured, the assembly stability of the capacitor is improved, and rapid production and manufacturing of the capacitor are realized.

Owner:深圳奥凯普电容器有限公司

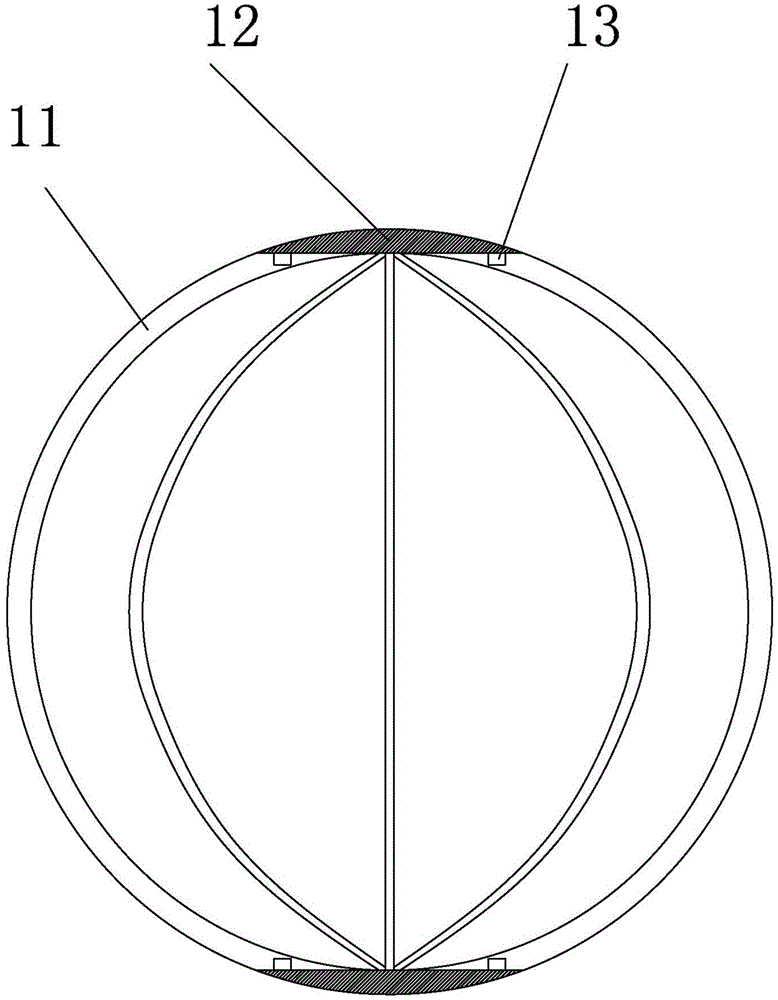

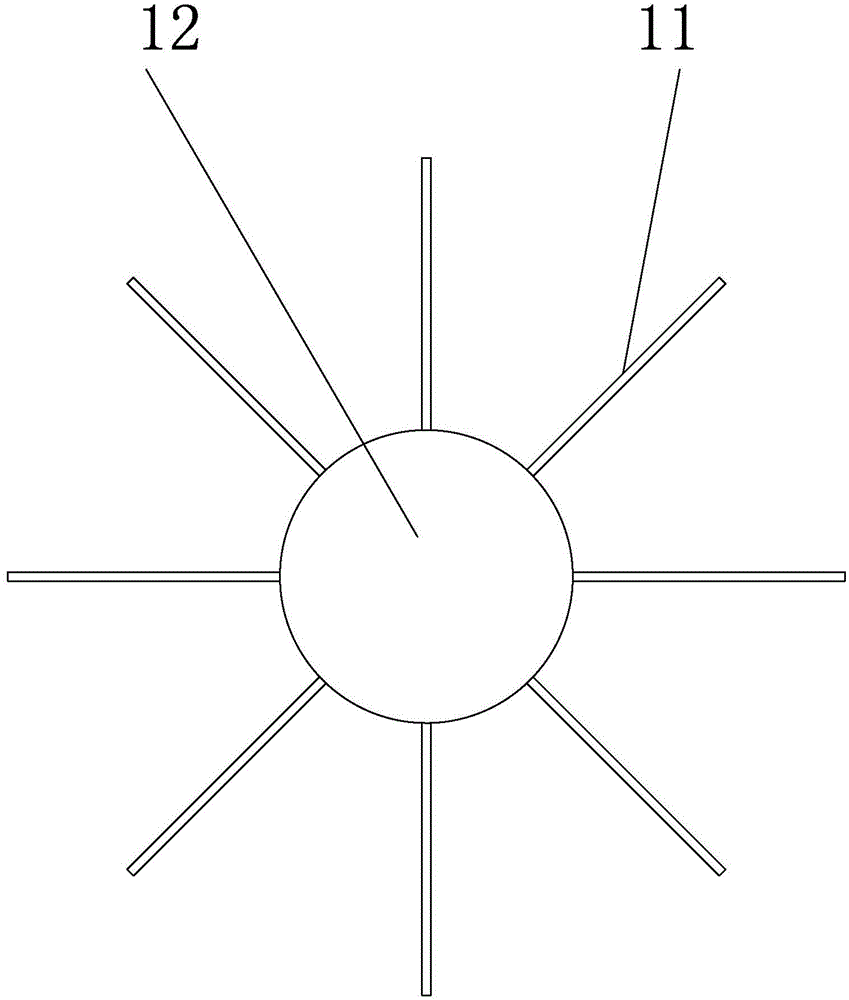

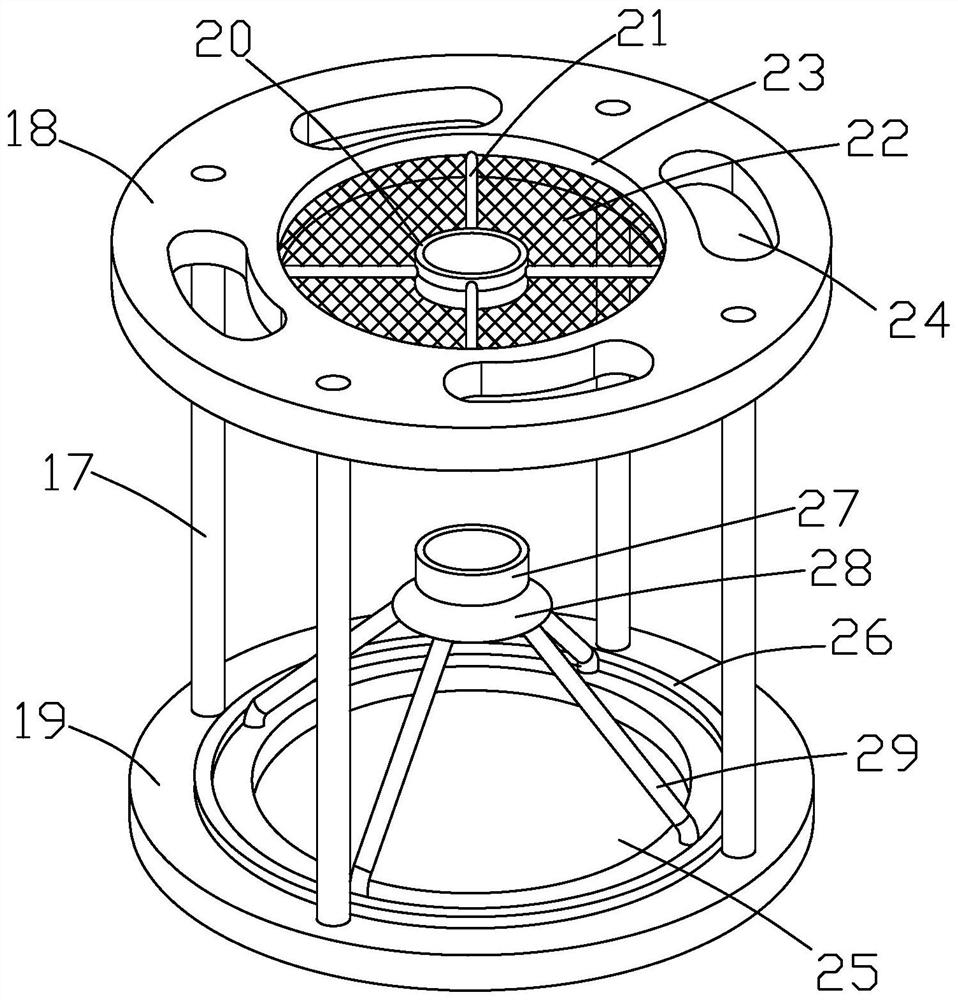

Seamless table tennis ball with skeleton and manufacturing technology thereof

ActiveCN105617622AReduce process stepsRapid manufacturingHollow non-inflatable ballsManufacturing engineeringIndustrial engineering

The invention discloses a seamless table tennis ball with a skeleton and a manufacturing technology thereof. A shell of the seamless table tennis ball with the skeleton comprises circular-arc longitude skeleton bodies. A spherical structure is defined by the multiple longitude skeleton bodies, and the two ends of the multiple longitude skeleton bodies are connected into a whole through top covers to form the elastic spherical skeleton; a fine net layer connected with the skeleton into a whole is arranged outside the skeleton; a glue connection layer is arranged outside of the fine net layer; a PVC ball shell integrally formed through injection molding is arranged outside the glue connection layer. The defects that a hemisphere-glue-type table tennis ball in the prior art is prone to damage, and the service life is not long; meanwhile, production steps are excessive, and consumed time is overlong are overcome.

Owner:浙江曙光体育用品有限公司

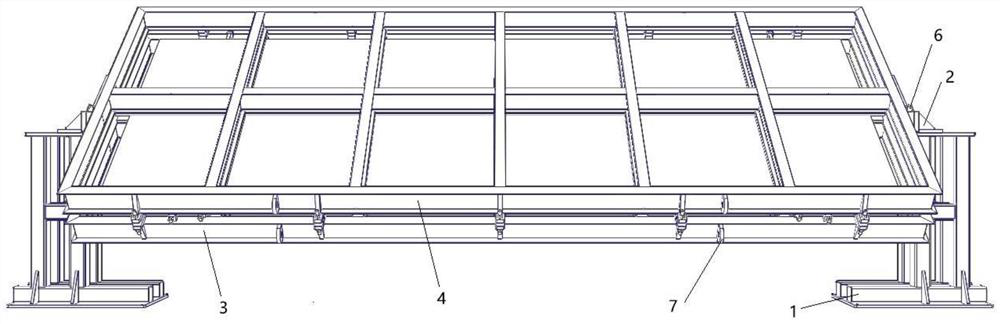

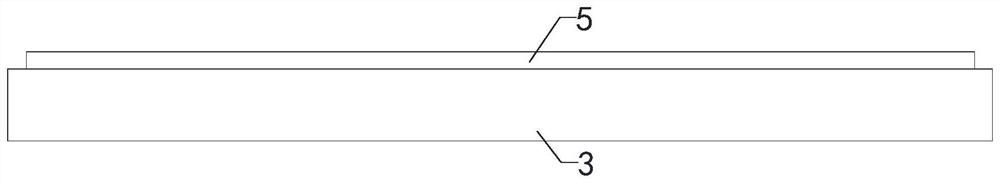

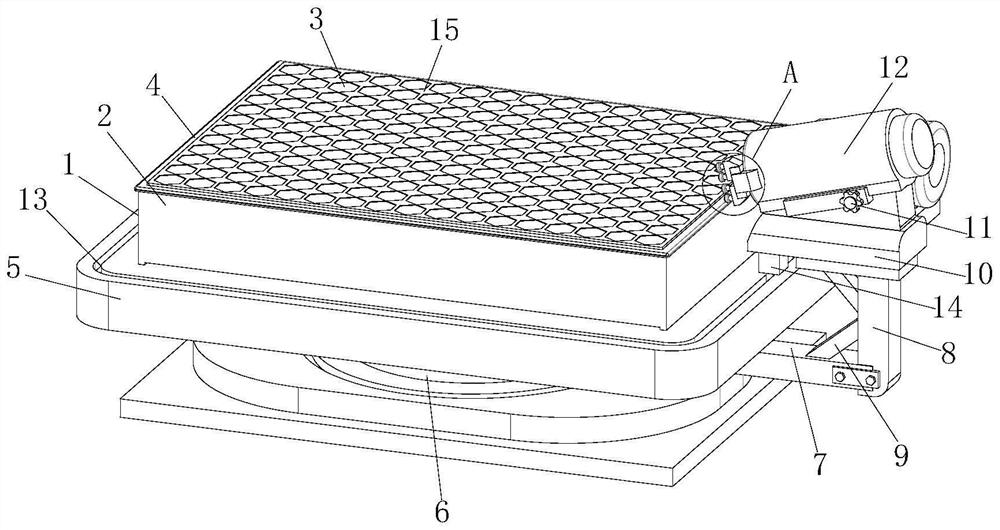

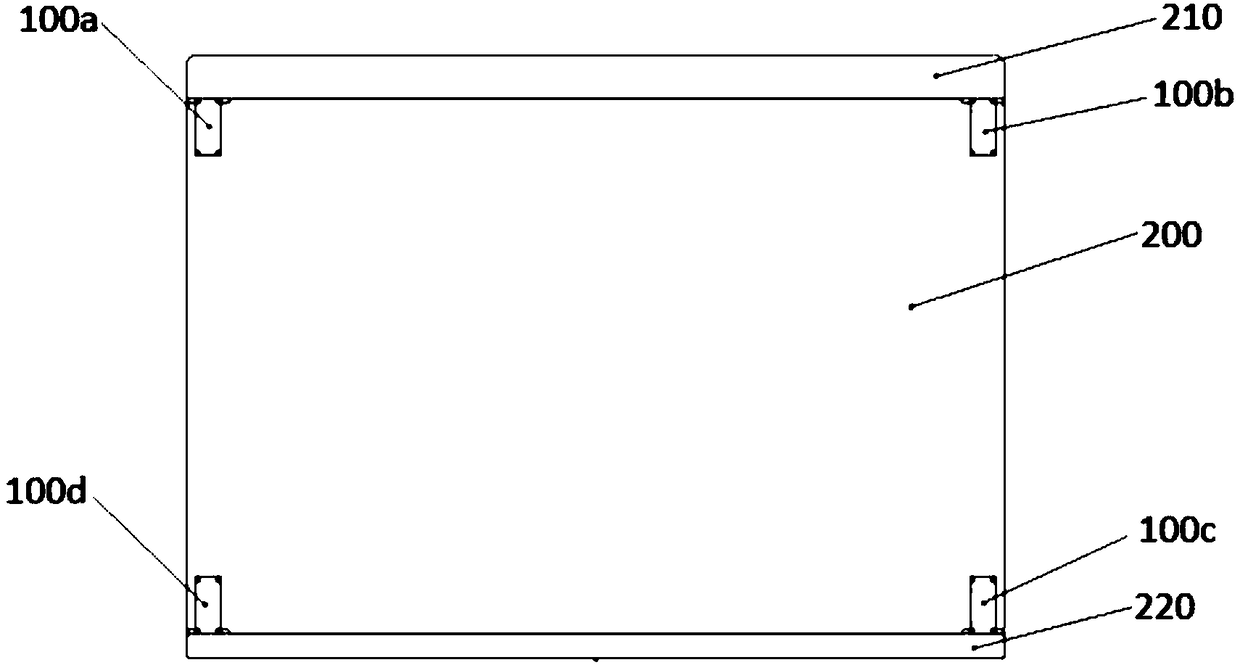

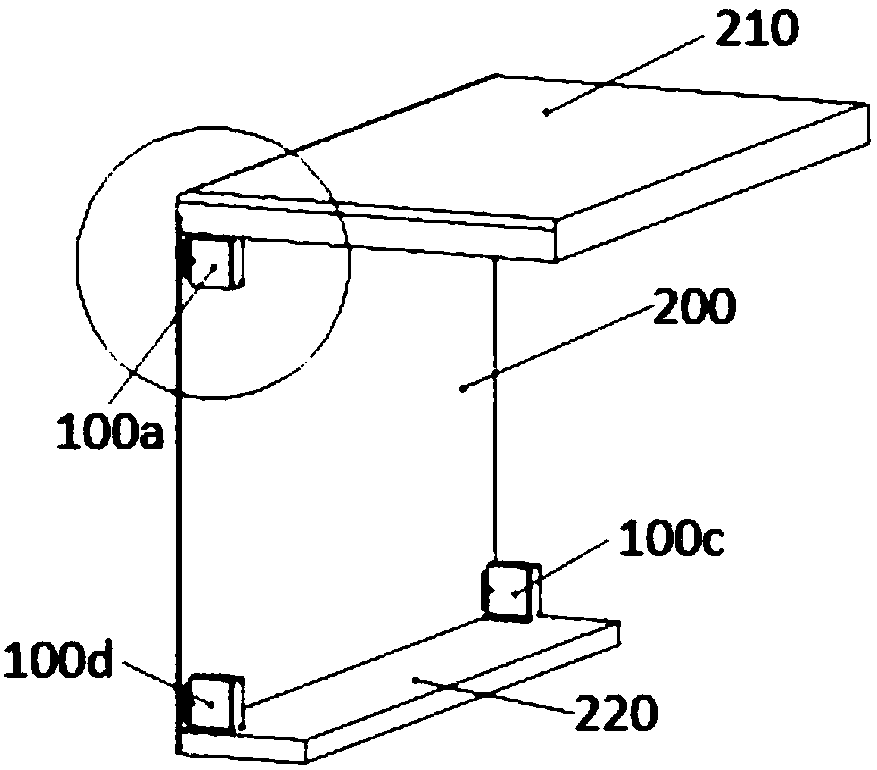

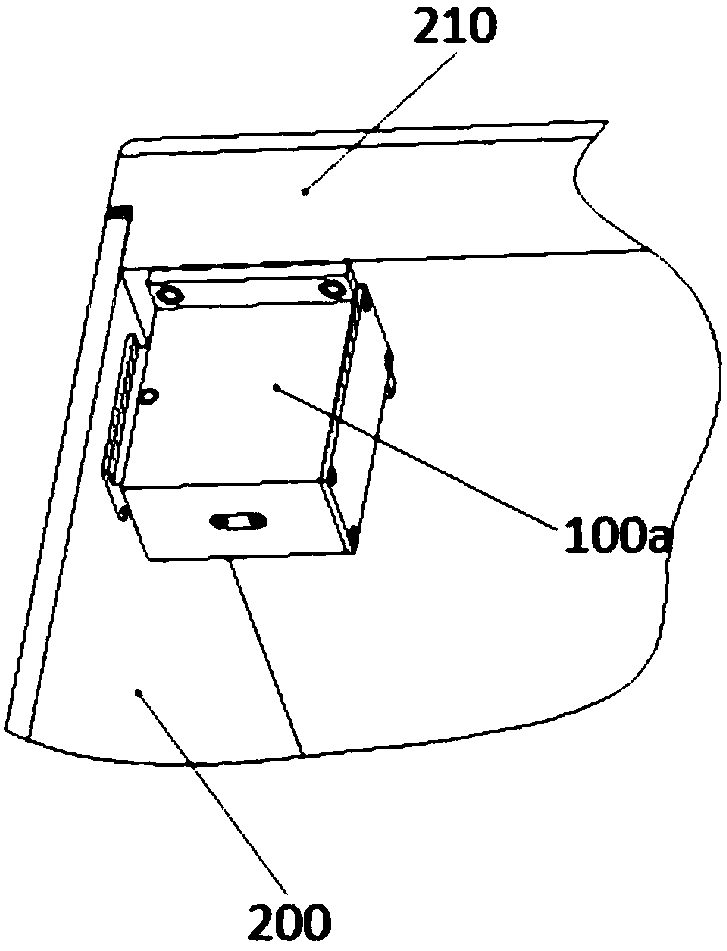

Hoisting and overturning device applied to machining of large panel machine

PendingCN114314291AEasy to operateSolve the problem of force deformationLoad-engaging elementsMachineMachining process

The invention relates to the technical field of machining, in particular to a hoisting and overturning device applied to machining of a large panel, which adopts a sandwich structure, clamps and fixes a product by two overturning platforms, forms a viaduct type gantry structure with upright posts on two sides, replaces a traditional hoisting and overturning mode, is convenient to operate, safe and reliable, and has high practicability. The problem that a product deforms due to stress in the overturning process is solved, hoisting and overturning in the machining process of large panels with different boundary dimensions and precision requirements can be completed through one set of device, and rapid and high-precision production and manufacturing are achieved; comprising a first turnover platform and a second turnover platform which are fixed through bolts, a cushion block which enables the first turnover platform and the second turnover platform to keep a certain distance is fixed to the first turnover platform, and the turnover assembly further comprises two rotating shafts matched with the V-shaped seats.

Owner:BEIJING XINLI MACHINERY

A microdroplet for cell-free protein synthesis and its preparation method

ActiveCN107349882BRapid manufacturingUniform sizeSequential/parallel process reactionsFermentationOil phaseCell-free protein synthesis

The invention discloses micro-droplets for cell-free protein synthesis and a preparation method thereof. The method includes the steps that firstly, a micro-fluidic chip device is used; 2, raw materials for protein synthesis are mixed to serve as a water phase, and the water phase is injected from a water phase inlet 6; an oil phase is injected from an oil phase inlet 4; in a cross channel 13, the water phase disperses under the shear force of the oil phase to form water-in-oil micro-droplets, and the micro-droplets are collected from a micro-droplet outlet 7 and then put into a thermostatic reaction vessel. According to the method, the micro-droplets can be rapidly prepared through the micro-fluidic chip device, and the obtained micro-droplets are uniform in size and stable in structure, and can provide a site for in-vitro protein synthesis; due to the unique microscale of the micro-droplets, part of the micro-droplets are used for simulating a cell environment so that a protein synthesis system working in the cell environment originally can obtain a similar environment, which facilitates the work of the protein synthesis system. Protein synthesis can be quantified, and the micro-droplets can be applied to detection and diagnosis.

Owner:TIANJIN UNIV

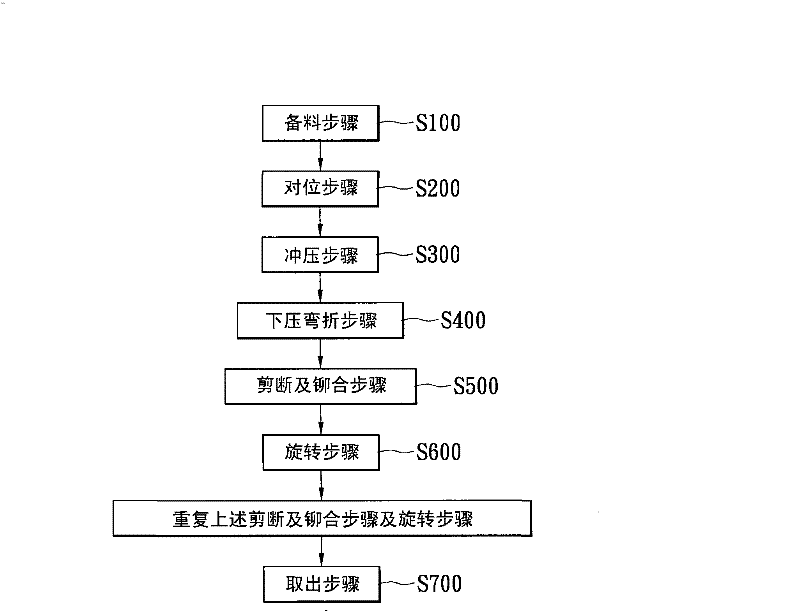

Manufacturing method of cam component and its application in textile machinery

The manufacturing method of the cam component is to split the whole part model of the cam component into a relatively simple wheel edge part and a relatively complex shaft core part through the part design method of changing the whole into parts, and adopts the molding method in the powder metallurgy process The rim part of the cam part is produced by sintering process, the shaft core part of the cam part is produced by MIM process, and the sintered wheel is placed in the cavity of the "assembly-shaping" integrated tool under the condition of heating at least the finished sintered wheel part The finished edge part is hot-press assembled to the outer ring of the finished sintered shaft core part, and at the same time, the shaping of the whole part of the cam part is completed in the cavity. This method enables the complex shape of the shaft core to be well realized in injection molding, while the wheel edge can be quickly manufactured in a low-cost, less-adhesive, high-pressure and high-density manner. Shaping, assembly, and extrusion are completed in one step. Manufacturing The size, shape and mechanical properties of the products meet the requirements. This method is especially suitable for the manufacture of cam parts in textile machinery.

Owner:SANYANG TEXTILE

A ferrule-type high-pressure oil pipe joint intelligent manufacturing equipment

ActiveCN112828757BPlay the role of anti-skid fixationAvoid noiseEdge grinding machinesGrinding carriagesControl engineeringProcess engineering

The invention provides a ferrule-type high-pressure oil pipe joint intelligent manufacturing equipment, which relates to the technical field of manufacturing equipment, to solve the problem that when the existing high-pressure oil pipe joint manufacturing equipment is in use, due to vibration to remove burrs, it is easy to cause the equipment to shake, and it is easy to break the equipment. The problem of displacement occurs after long-term use, including the main body, the discharge part, the feeding port, and the support part; the main body is a rectangular structure, and the front end of the main body is provided with a rectangular outlet; the discharge part is installed at the right end of the main body. The support is used to set the bottom corner of the main body, so that the support can be in contact with the ground, and then firmly in contact with the ground. When the device is in use, the spring pushes the moving rod to move downward, so that the contact It can always be in contact with the ground. Since the contact piece is made of rubber and the bottom is provided with a wedge-shaped groove, it can effectively contact with the ground, thereby buffering the impact force and avoiding abnormal noise or displacement caused by the contact between the support piece and the ground.

Owner:东营市三和石油装备有限公司

Mould used for injection molding and manufacture method for composite article

ActiveCN102069565BSimplify the manufacturing processRapid manufacturingCoatingsInjection mouldingInjection molding machine

The invention provides a mould used for injection molding and manufacture method for a composite article. In a mould used for injection molding used in manufacture of a composite article, the composite article forms a decorative layer on the surface of a metal body (20) provided with a protruding part (20a), and forms a resin part at the back side surface of the metal body (20), the mould used for injection molding is provided with: a first mould (1) is provided with a metal body (20); a second mould (2) and the first mould (1) are in spotting, a mould cavity used for injecting resins is formed between the first mould (1) and the metal body (20); and a decorative sheet keeping mechanism, before spotting of the first mould (1) and the second mould (2), disposes a transfer sheet (12) at a position, from which the transfer sheet gets away, of a molded surface of the second mould (2), and in the meantime that the transfer sheet (12) is pressed by and towards the protruding part (20a) of the metal body (20), makes the transfer sheet (12) be in a contact with the protruding part (20a) along the protruding part (20a).

Owner:NISSHA PRINTING COMPANY

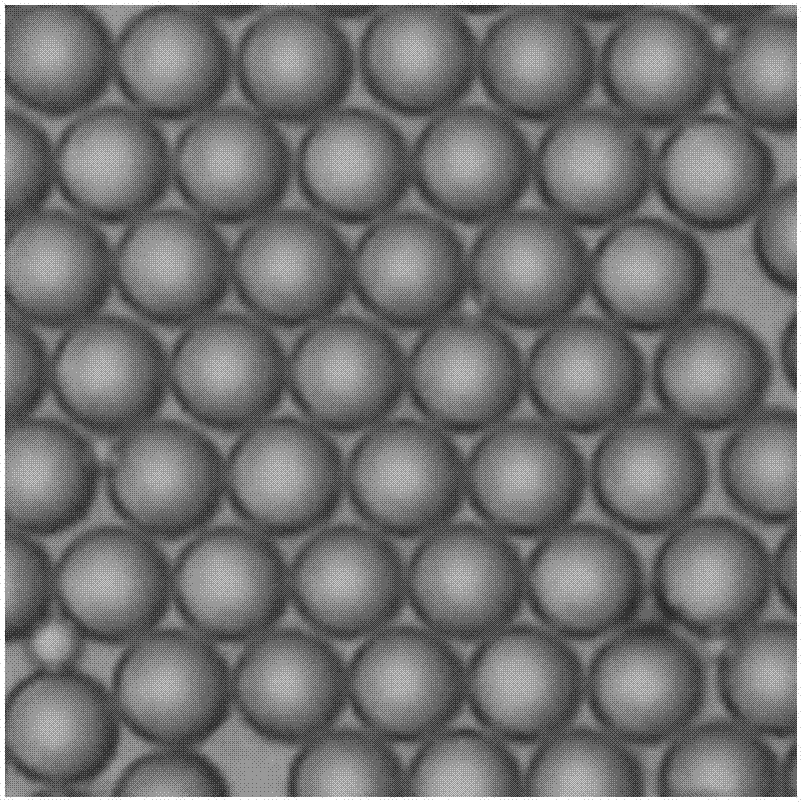

Intensive packaging method of LEDs

ActiveCN103022326BSimple methodReasonable methodSolid-state devicesSemiconductor devicesPhosphorEngineering

The invention discloses an intensive packaging method of LEDs. With a plurality of LED substrates, provided with bonding wires, as processing objects, and a screen and a scraper as processing devices, the intensive packaging method of LEDs includes the steps of a, attaching the screen with a plurality of through holes to the substrates; b, pouring phosphor-bearing transparent glue onto the screen, evenly spreading the glue with the scraper, and taking off the screen; c, placing the substrates coated with the phosphor-bearing transparent glue in a dryer for drying; d, attaching the screen to the substrates processed in the step c, pouring the transparent glue into the screen, evenly spreading the glue with the scraper, taking off the screen; e, placing the substrates processed in the step d in the dryer for drying; and finishing packaging. The through holes are in one-to-one correspondence to a plurality of LED chips, and the LED chips are higher than the upper surface of the screen.

Owner:CHANGZHOU GALAXY CENTURY MICROELECTRONICS CO LTD

A partial discharge suppression method at the flange of a gis/gil support insulator

ActiveCN113470907BRapid manufacturingImprove interfacial bond strengthImage enhancementAdditive manufacturing apparatusEpoxyElectrical field strength

Owner:XI AN JIAOTONG UNIV

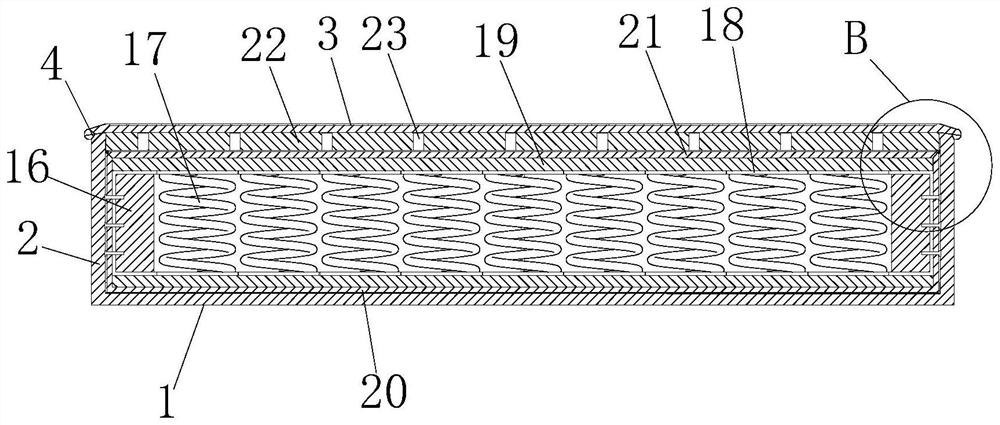

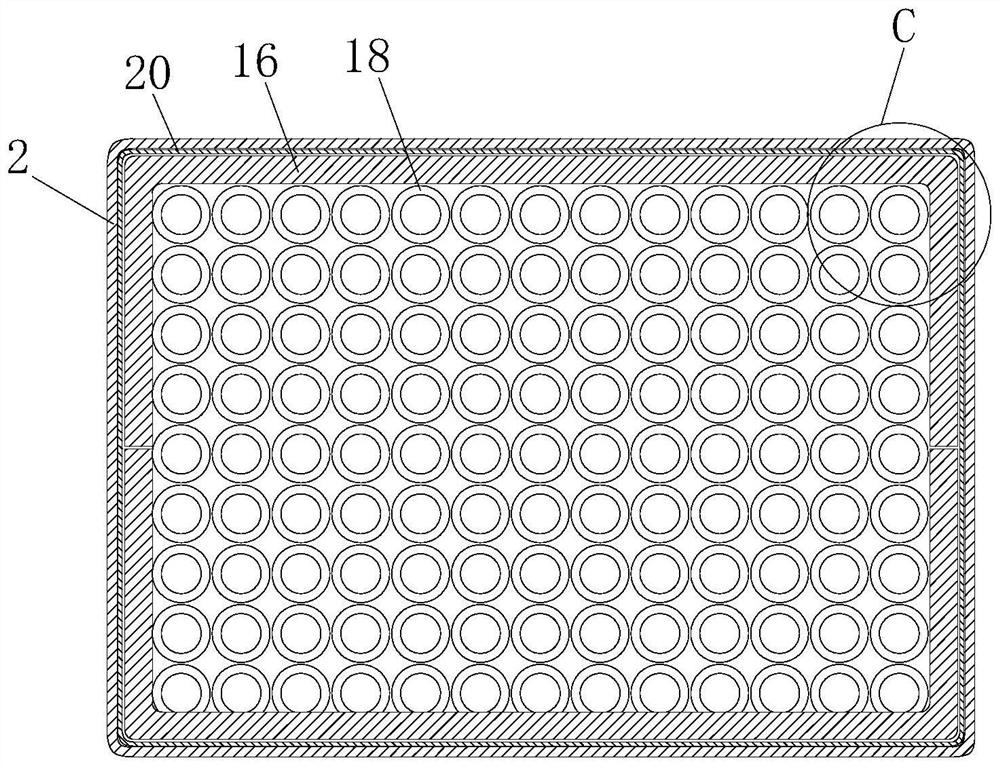

Stain-resistant antibacterial composite latex mattress and production method thereof

PendingCN114794790AReduce manufacturing costFacilitate rapid manufacturingStuffed mattressesSpring mattressesPolymer chemistryEngineering

The invention discloses a stain-resistant antibacterial composite latex mattress and a production method, and relates to the technical field of furniture, the stain-resistant antibacterial composite latex mattress comprises a mattress body, a workbench and cushioning springs, the cushioning springs are uniformly arranged in the mattress body, the cushioning springs are provided with spring rings, the spring rings are connected through spring connecting rings, the upper spring ring and the lower spring ring are provided with foam layers, and the foam layers are arranged on the workbench. The four sides of the cushioning springs are sleeved with polyurethane foam rings, the polyurethane foam rings and foam layers are sleeved with inner mattress wrapping layers, the upper ends of the inner mattress wrapping layers are connected with inner mattresses through second sewing edges in a sewing mode, latex mattresses are arranged above the inner mattresses in a cushioned mode, the inner mattress wrapping layers and the latex mattresses are sleeved with outer mattress wrapping layers, upper mattresses are arranged above the latex mattresses in a cushioned mode, and the latex mattresses are connected with the upper mattress wrapping layers in a sewn mode. And the upper mattress and the outer mattress wrapping layer are sewn and connected through a first sewing edge. The latex mattress and the spring mattress are combined, the spring mattress is more comfortable to use through a plurality of mattress layers, the production cost of the latex mattress is reduced, and the latex mattress is convenient to produce and manufacture quickly and suitable for popularization.

Owner:安徽爱德福乳胶制品有限公司

An automatic capacitor assembly device

ActiveCN112927933BEnsure assemblyImprove stabilityElectrolytic capacitorsTerminal applying apparatusSlide plateControl theory

The application relates to an automatic capacitor assembly device, which includes a frame, on which there are vibrating pans, vibrating rails, and station trays. The rack is located between the element conveying track and the station plate and is provided with a clamping device. The clamping device includes a slide plate, an element positioning jaw, an element clamping assembly and a slide plate driving assembly. There are two slide plates. Surface sliding connection, the element positioning jaw is fixed on the side of the slide plate away from the frame, the element clamping component is set on the slide plate and located at the discharge end of the element positioning jaw, the slide plate driving component is set in the frame, and the frame is located on the element A batch feeding device is arranged above the conveying track. The application can effectively improve the accuracy of the assembly of the element and the colloidal particles, thereby ensuring the subsequent assembly of the element, which is conducive to improving the stability of the capacitor assembly and realizing the rapid production and manufacture of the capacitor.

Owner:深圳奥凯普电容器有限公司

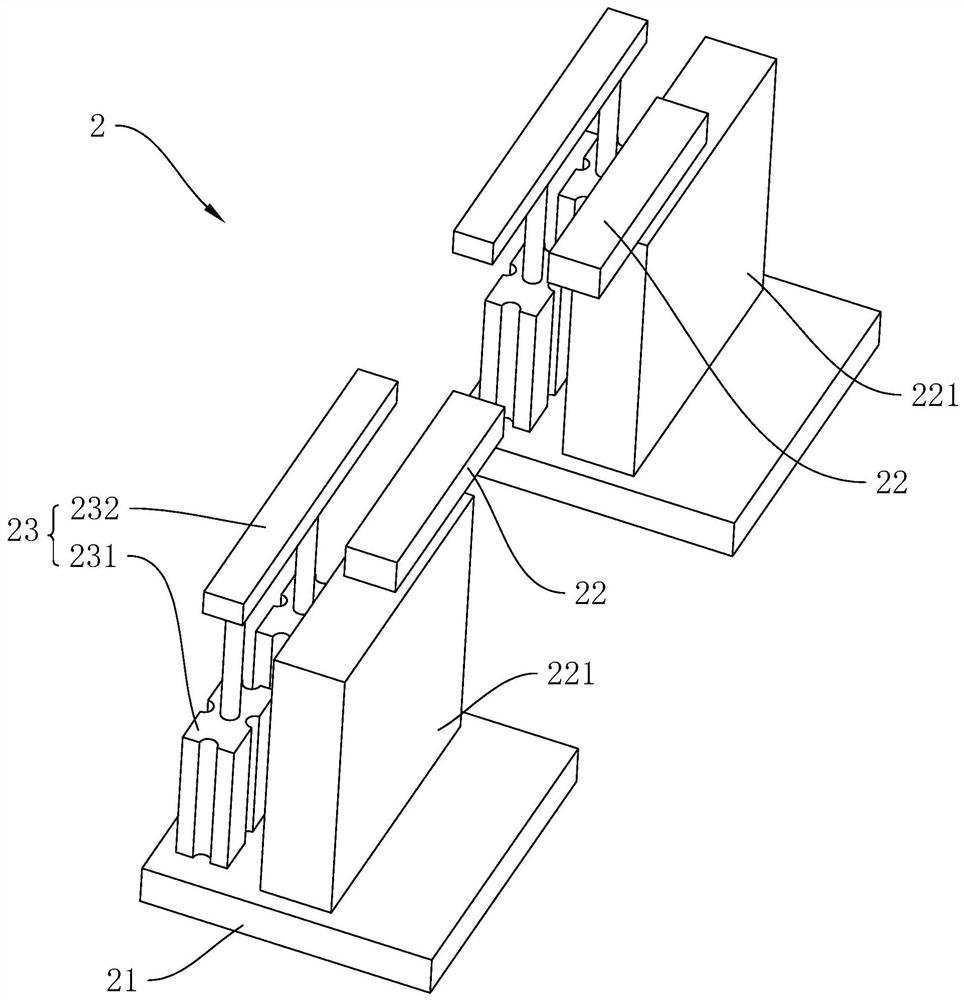

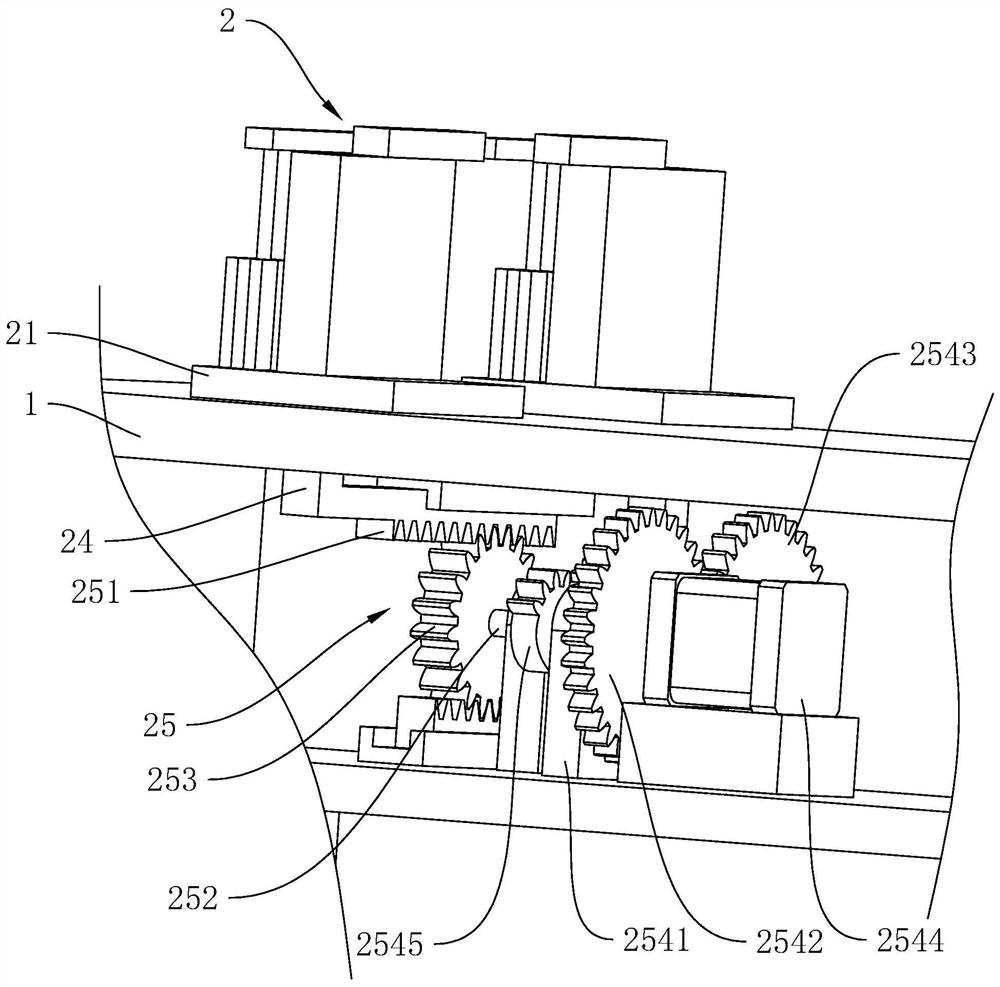

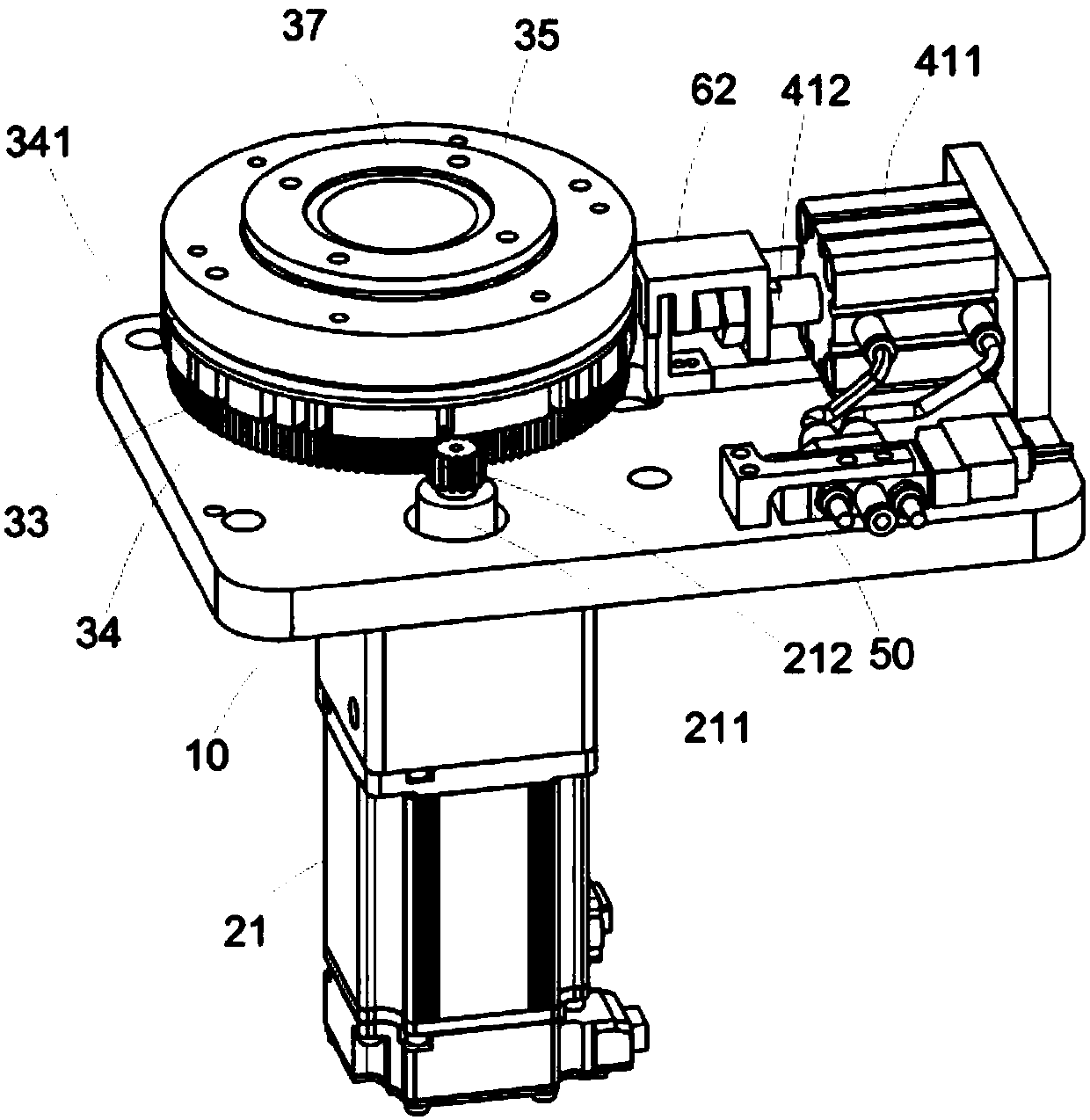

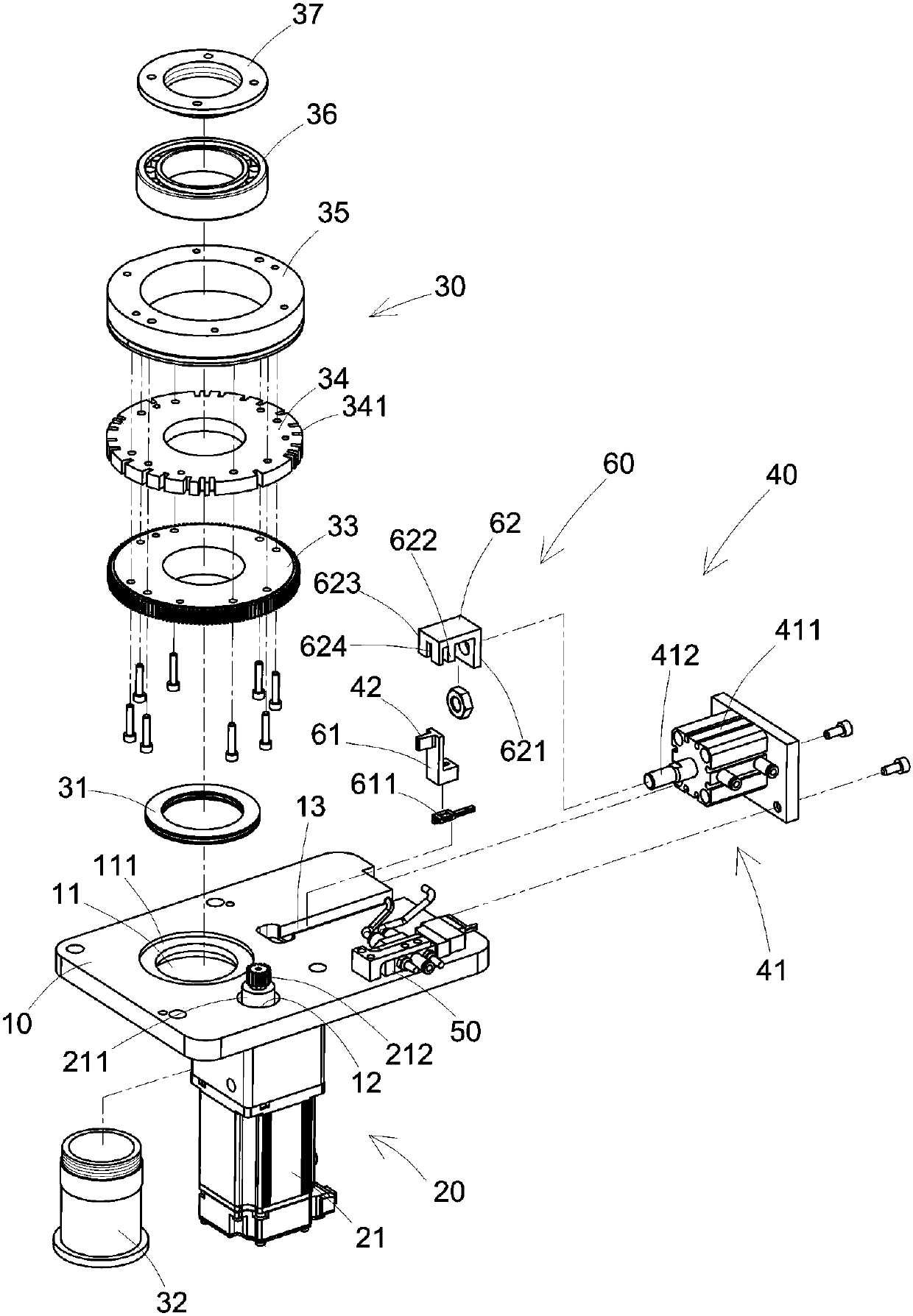

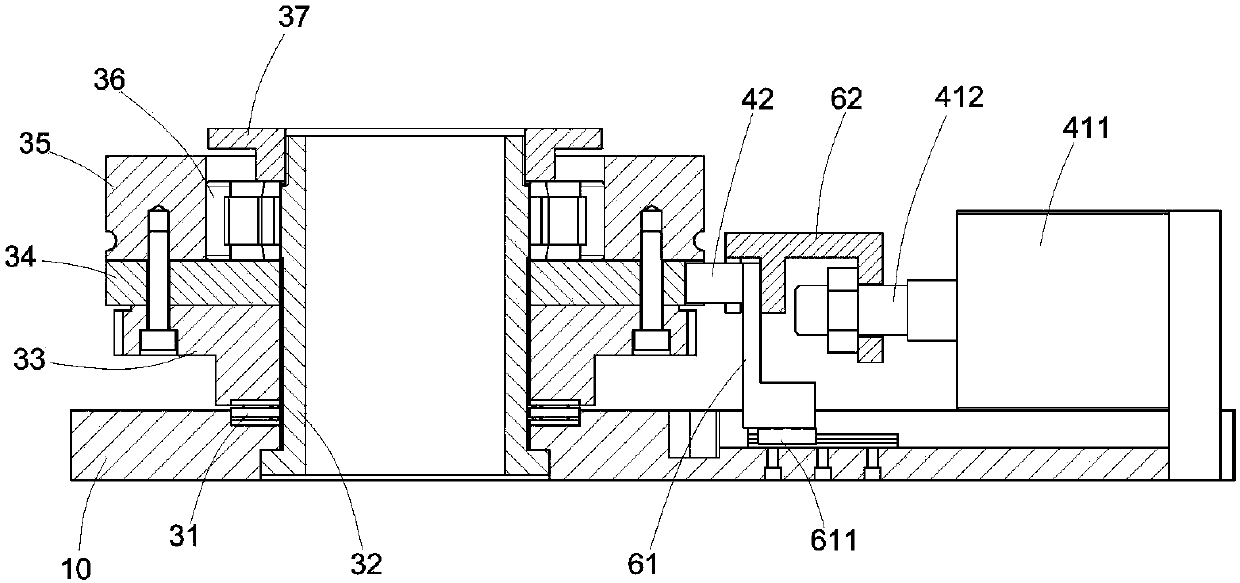

Rotating platform structure

InactiveCN106141697BWith precisionGuaranteed precisionLarge fixed membersEngineeringMechanical engineering

The invention discloses a rotating platform structure. The rotating platform structure consists of a basal plate, a first power source, a rotating set and a stopper set; the first power source is fixed on the basal plate; a first bearing of the rotating set is mounted on the basal plate; a penetrating sleeve is used for penetrating through the basal plate and the first bearing; a first disc, a second disc with multiple gaps formed by equal angles, a third disc and a second bearing sleeve the penetrating sleeve in sequence; the first, second and third discs are fixed on the penetrating sleeve by using a sealing cover; the stopper set is mounted on the top surface of the basal plate, and consists of a second power source and a stop piece; the second power source is connected with the stop piece; and through acting of the second power source, the stop piece stops the gaps of the second disc, so that the deviated angle can be forcedly corrected, the angle dividing precision and the machining object precision are guaranteed, the manufacturing is fast, and the working efficiency is improved.

Owner:萧澔尧

Automobile windshield and automobile window glass automatic catapulting type escape device

The invention discloses an automobile windshield and automobile window glass automatic catapulting type escape device. The device comprises a shell, an articulating mechanism, an armature, an electromagnet, main pushing springs and elastic stop block mechanisms, wherein first through holes are symmetrically formed in the top face and the bottom face of the shell, an end cover is fixedly installedon one side of the shell, and articulating through holes are formed in the other side of the shell; the articulating mechanism comprises a first guide rail arranged in the shell and a second guide rail arranged outside the shell, and articulating rods are arranged between the first guide rail and the second guide rail and can penetrate through the articulating through holes; one side of the armature is fixed to the first guide rail, and stop block grooves are formed in the upper surface and the lower surface of the armature; the electromagnet is fixed to the center position of the end cover; one end of each main pushing spring is fixed to the end cover, and the other end of each main pushing spring is fixed to the other side of the armature; and the elastic stop block mechanisms are detachably arranged in the first through holes.

Owner:JILIN UNIV

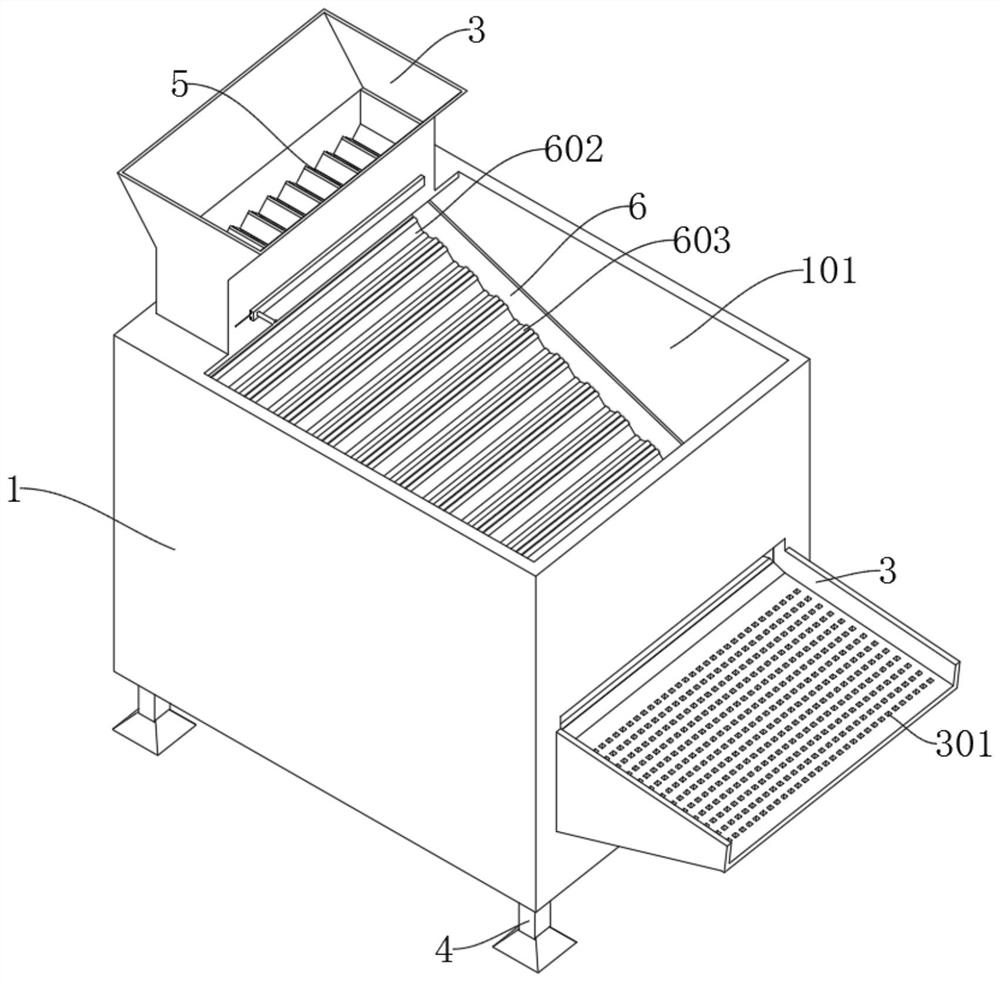

Comprehensive cereal-fruit oatmeal and preparation method thereof

InactiveCN111466517AEasy to cleanWell mixedEngine sealsTransportation and packagingBiotechnologyWalnut Nut

The invention relates to the technical field of oatmeal preparation, and discloses comprehensive cereal-fruit oatmeal and a preparation method thereof. The oatmeal is prepared from, by weight in parts, 30 parts of wheatmeal, 5-8 parts of walnut powder, 6-10 parts of almond powder, 10-12 parts of dried mango, 10-13 parts of dried strawberry, 3-5 parts of an emulsifying agent, 3-5 parts of peanut oil and 5-8 parts of white granulated sugar. The preparation method includes as follows: a shell is included, a cover plate is fixed at the end part of the shell, and a stirring mechanism is fixed on the cover plate; a hopper is fixed on the top of the shell; a feeding port communicating with an inner cavity located inside the shell is installed at the bottom of the hopper; the stirring mechanism and a discharging mechanism which are located in the inner cavity are installed inside the shell; and the stirring mechanism is connected to the discharging mechanism.

Owner:ANHUI QIUGUO FOOD

Intelligent manufacturing equipment for clamping sleeve type high-pressure oil pipe joint

ActiveCN112828757AIncrease contact areaStable supportEdge grinding machinesGrinding carriagesEngineeringMechanical engineering

The invention provides intelligent manufacturing equipment for a clamping sleeve type high-pressure oil pipe joint, relates to the technical field of manufacturing equipment, and aims to solve the problems that when existing manufacturing equipment for a high-pressure oil pipe joint is used, the equipment is easy to shake and is easy to displace after being used for a long time due to the fact that burrs are removed through vibration. The intelligent manufacturing equipment for the clamping sleeve type high-pressure oil pipe joint comprises a main body, a discharging piece, a charging port and supporting pieces; the main body is of a rectangular structure, and a rectangular outlet is formed in the front end of the main body; and the discharging piece is mounted at the right end of the main body; the supporting pieces are used for being arranged at the corner positions of the bottom of the main body, so that the supporting pieces can make contact with the ground and further make stable contact with the ground; when the device is used, springs eject movable rods to move downwards, and then contact pieces can be in the state of making contact with the ground all the time; due to the fact that the contact pieces are made of rubber and are provided with wedge-shaped grooves in the bottoms, effective contact with the ground is achieved, so that impact force is buffered, and abnormal sound or displacement generated when the supporting pieces make contact with the ground is avoided.

Owner:东营市三和石油装备有限公司

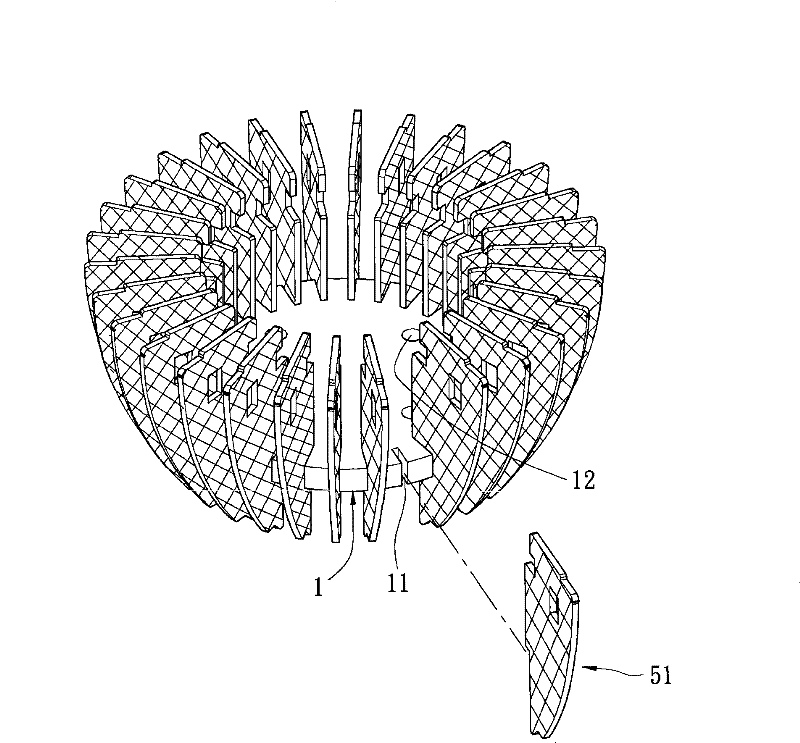

Manufacturing method of radiator

InactiveCN101829740BSimplified manufacturing methodPreventing conduction thermal resistance problemsHeat exchange apparatusMetal stripsManufacturing cost reduction

Owner:NENG TYI PRECISION INDS

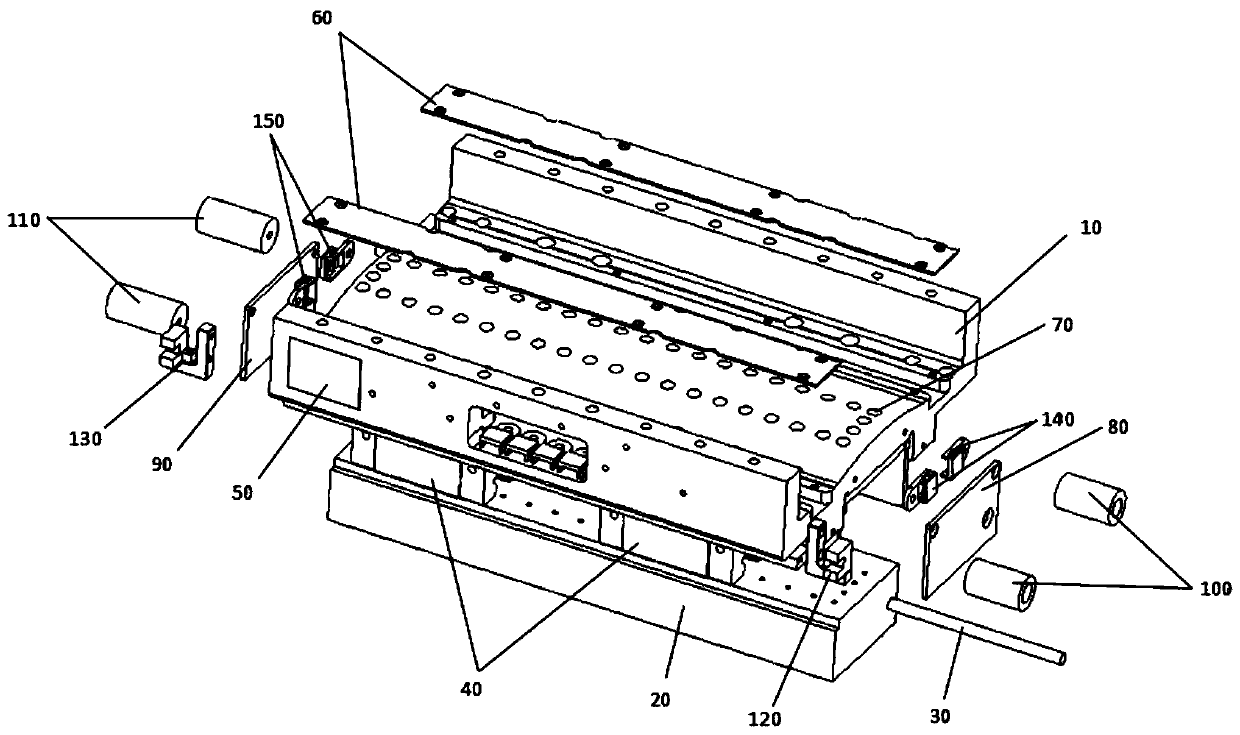

Linear motor rotor sliding table

ActiveCN111137031AHighly integratedSimple structureEngine sealsMagnetic circuit characterised by magnetic materialsMagnetLinear motor

The invention provides a linear motor rotor sliding table. A rotor sliding table body, a stator, a fixing shaft, at least one motor sliding block and a control board are included. The rotor sliding table body is arranged above the stator in a sleeving manner. The fixing shaft is arranged in the stator and penetrates through the stator. The motor sliding blocks are arranged on the two sides of thestator and fixed to the position below the rotor sliding table body. The control board is arranged on one side of the rotor sliding table body and is connected with the motor sliding blocks and a background controller. Through the above structure, the stator is changed into magnet materials, and the integration level of the stator is enhanced; in addition, a guiding screw and a coupler do not needto be arranged, and the structure of the linear motor rotor sliding table is simplified; through the manner of the arrangement of a size reading head, the work range is automatically judged, and thework efficiency of the linear motor rotor sliding table is improved; and the advantages that the structure is simple, rapid machining and manufacturing can be achieved during producing and manufacturing, cost is saved for enterprises, and the maximum value is created are achieved.

Owner:珠海市科迪电子科技有限公司

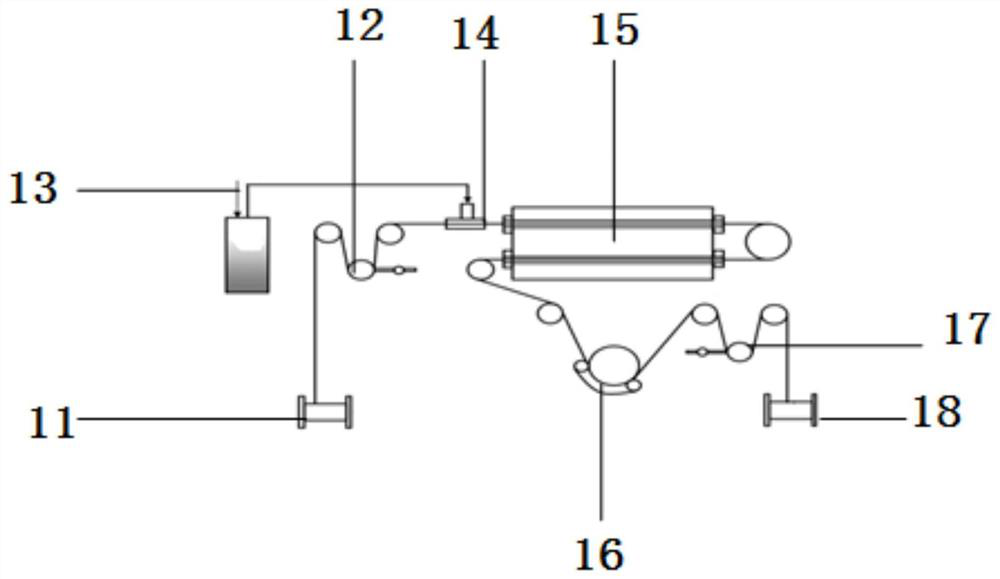

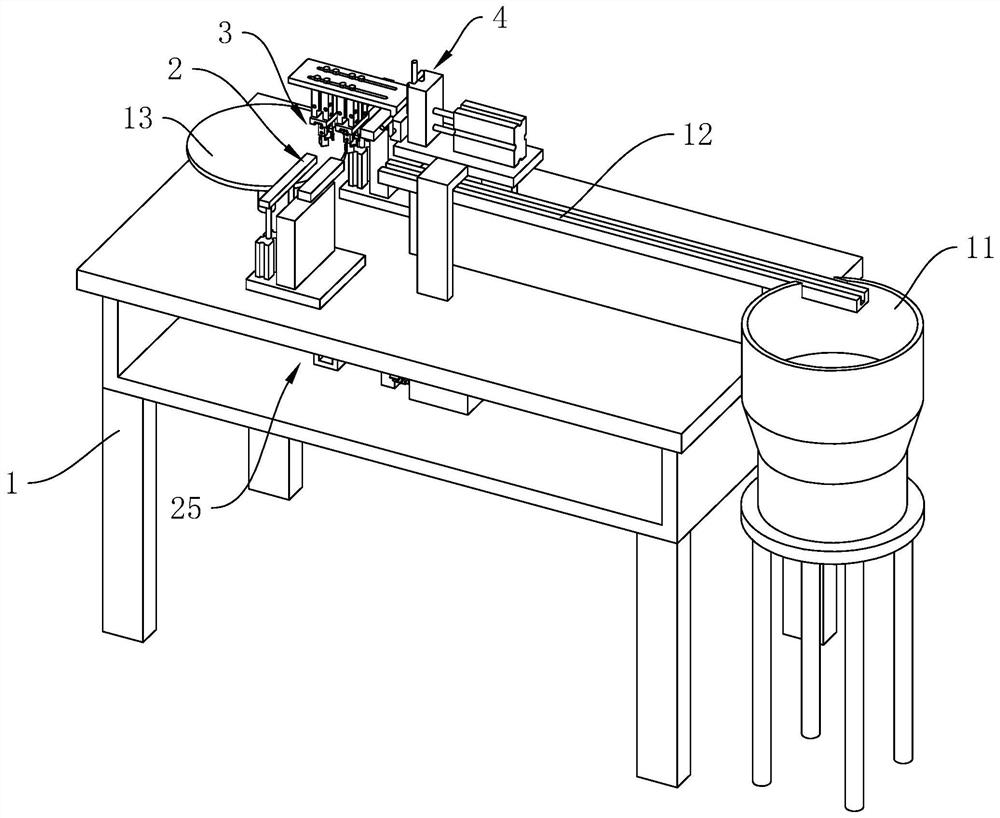

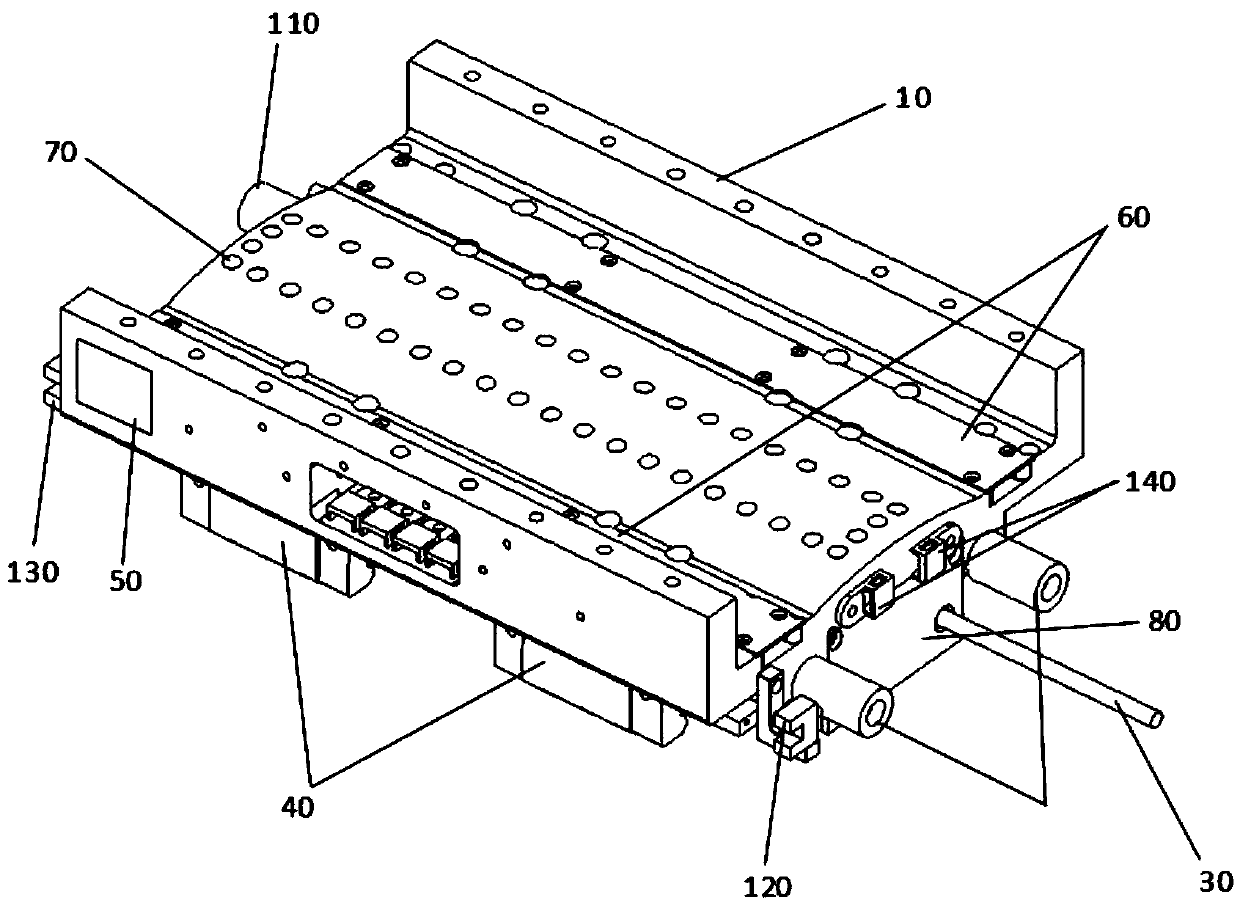

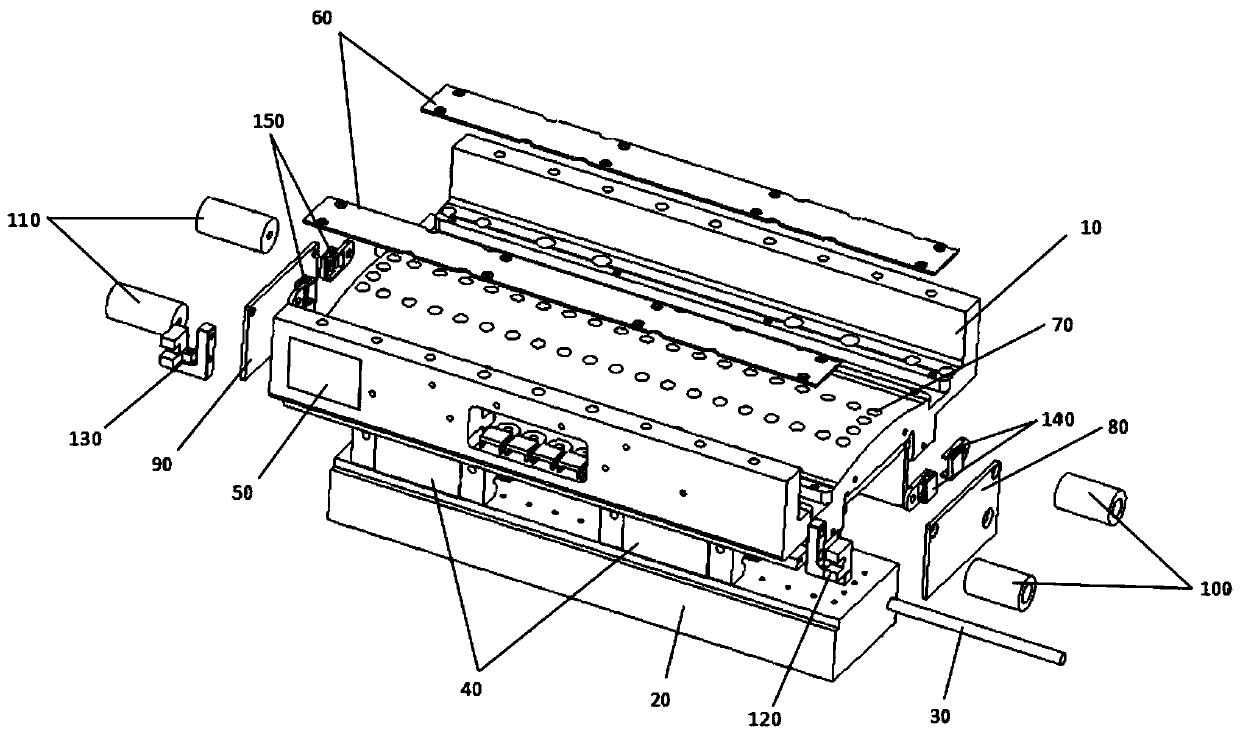

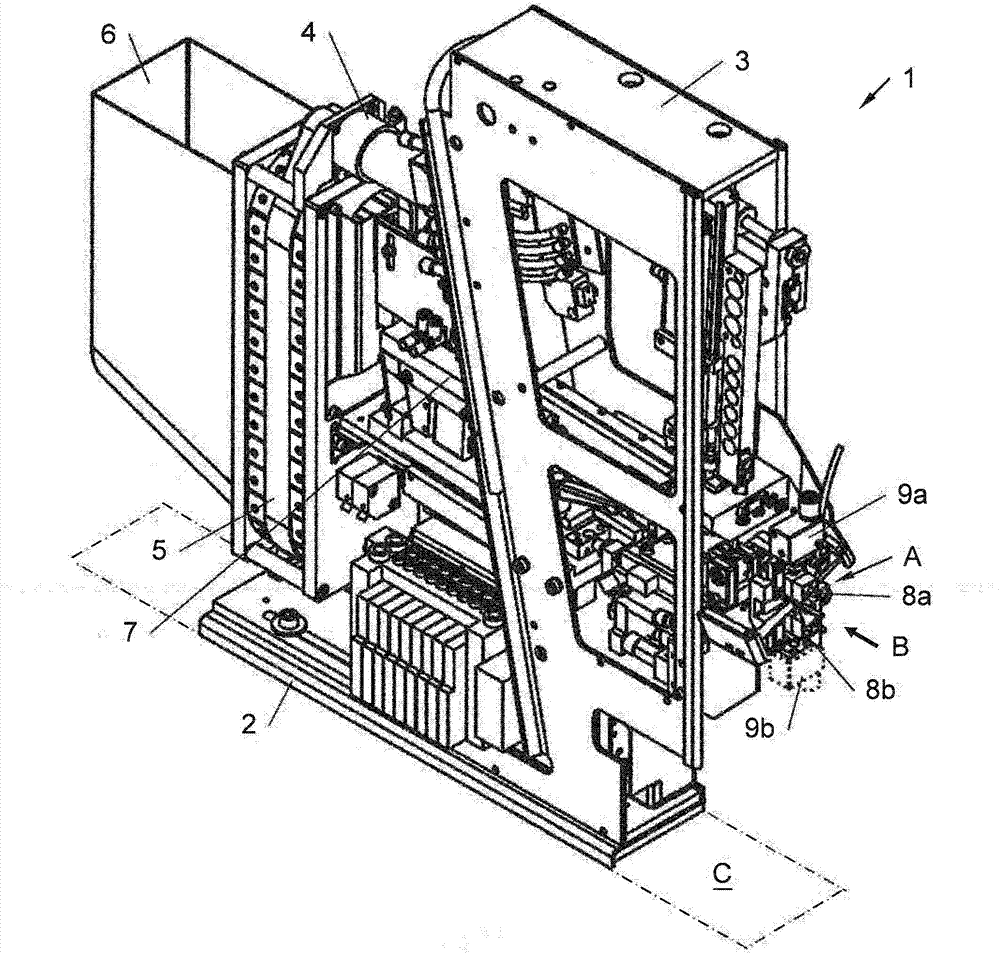

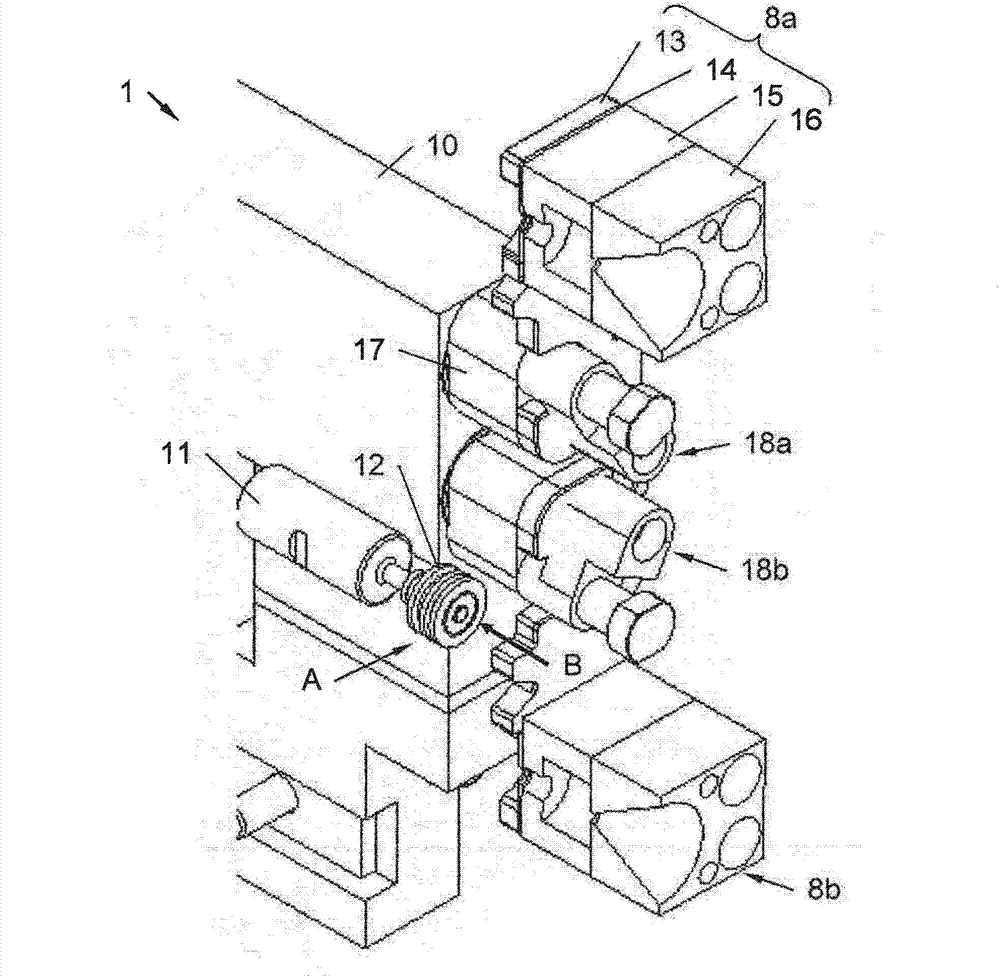

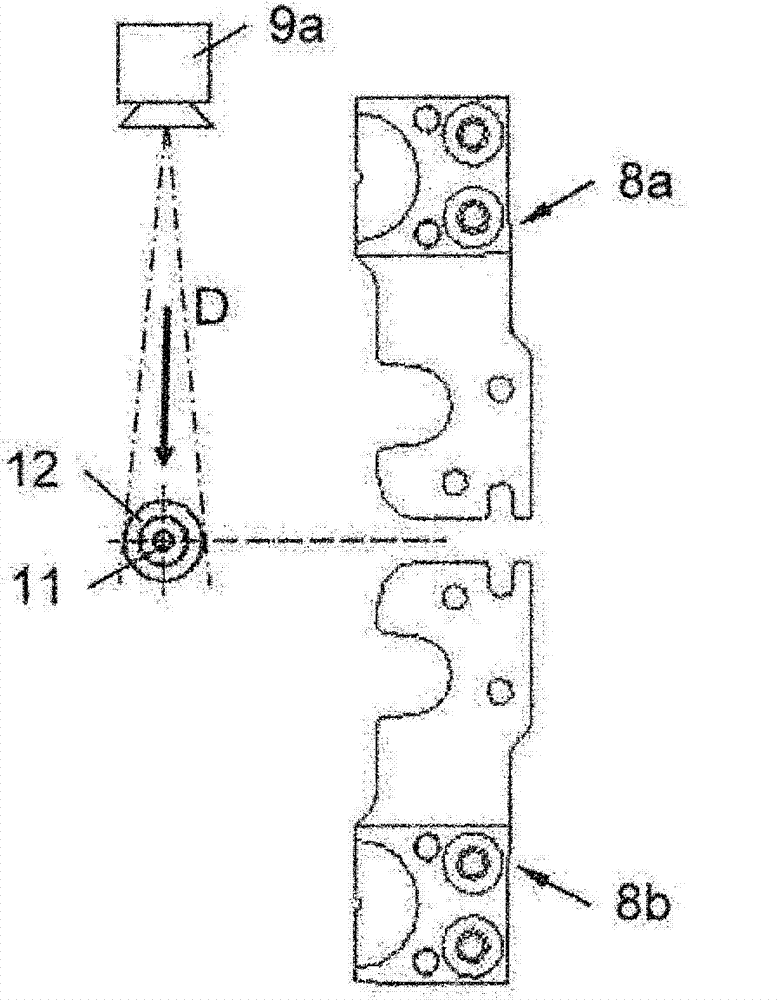

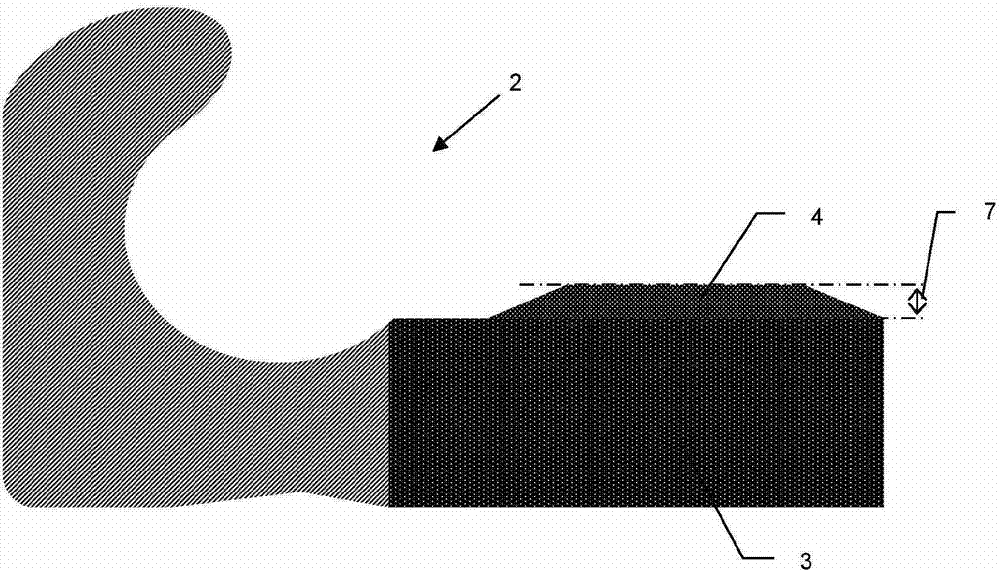

Machine for fitting cable bushings

ActiveCN103682935ARapid manufacturingLow manufacturing costAutomatic control devicesDustproof/splashproof/drip-proof/waterproof/flameproof connectionEngineering

The invention relates to a machine (1) for fitting a cable bushing (12) on a cable includes a mandrel (11) for receiving the cable bushing (12) and a cable in a fitting region (A), and further includes two rotatably mounted stripping jaws (8a, 8b) supported and arranged in the fitting region (A), and used for arranging the cable bushing (12) on the cable. The machine is also provided with a camera (9a, 9b) which is directed towards the fitting region (A). A rotation axis of at least one of the stripping jaws (8a, 8b) is at a lateral distance from ray-of-view (D) originating from the camera (9a,9b) and running through the fitting region (A). The stripping jaws (8a, 8b) may be opened to an extent that makes it possible for the camera (9a, 9b) to have an unimpeded view of the fitted cable bushing (12). Related methods for operating such machines (1) are also disclosed.

Owner:쉴로이니게르아게

Optical instrument having a stabilization element for mounting and adjusting an optical assembly in a holder, and mounting method for the stabilization element

The optical instrument comprises optical assembly (1b) with several optical element such as lens which defines an optical axis (8). An optical assembly holder (1a) has a shape so as to form a gap (13) with defined width between the optical assembly and holder. A stabilizing component (2) comprising stabilization elements (3a-3c) for stably connecting optical assembly and holder is provided in the gap. The stabilizing elements are deformed, so that elastic forces are acted on optical axis between assembly and holder in radial direction. The thickness of stabilizing element in an unassembled state is greater than width of gap. The optical assembly, holder and stabilizing component are connected in coarse-positioned state by inserting the optical assembly into the holder. An independent claim is included for method for mounting optical assembly to holder.

Owner:HEXAGON TECH CENT GMBH

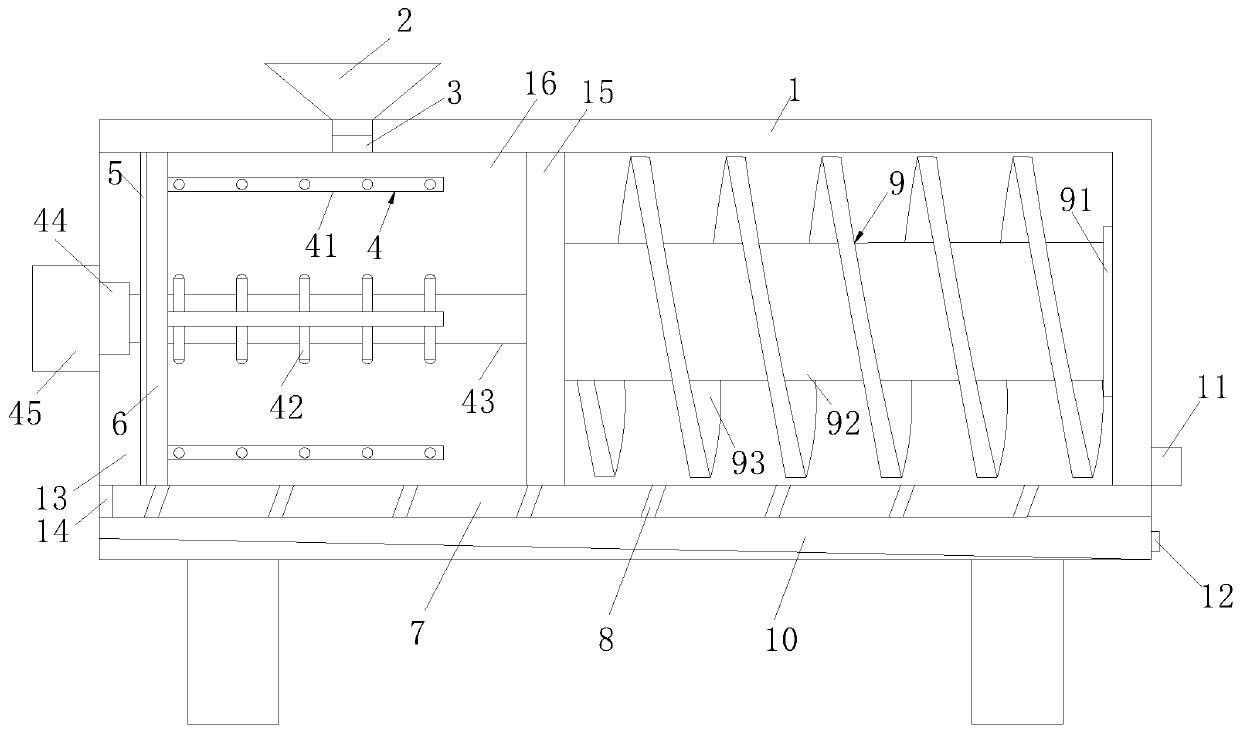

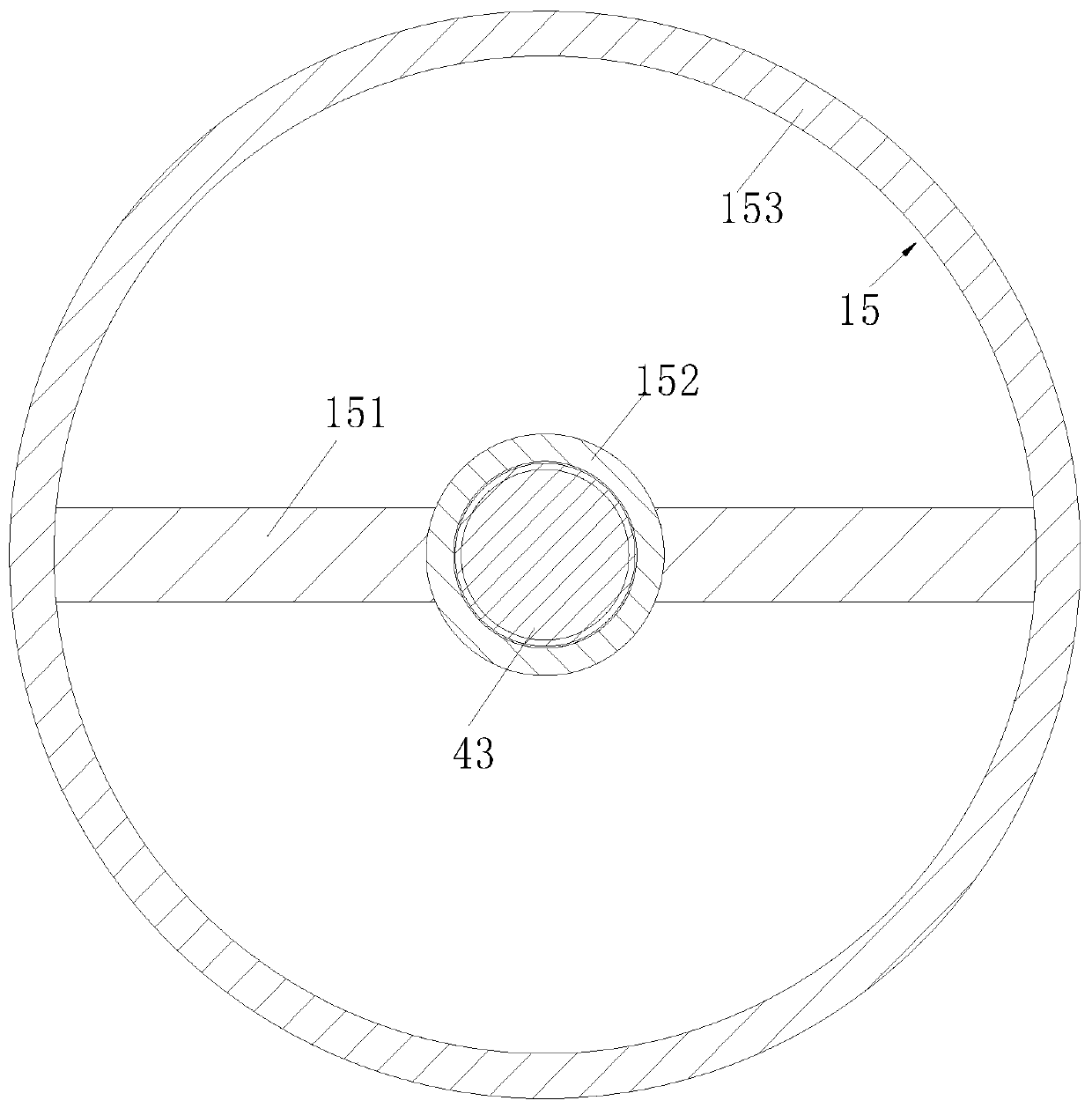

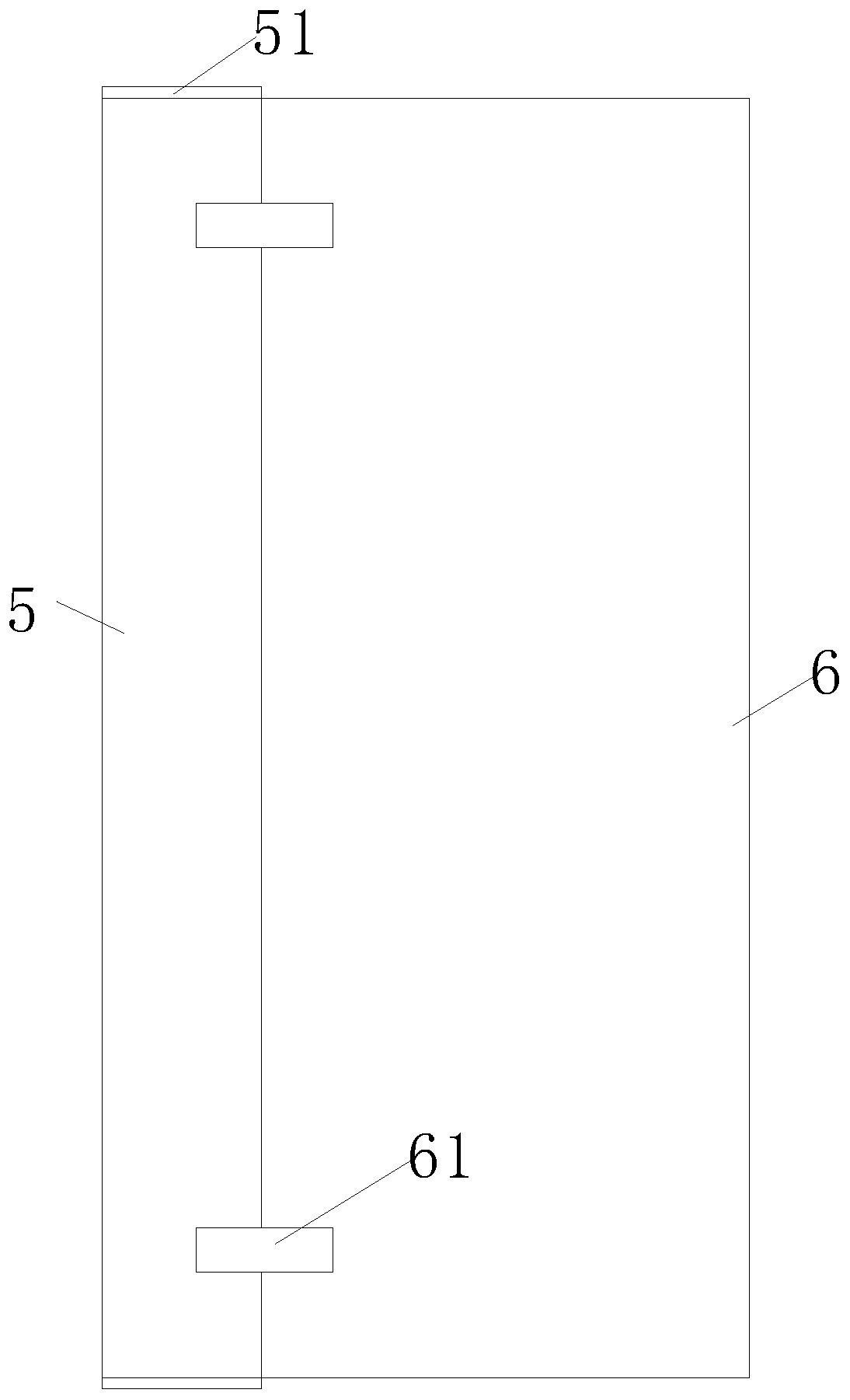

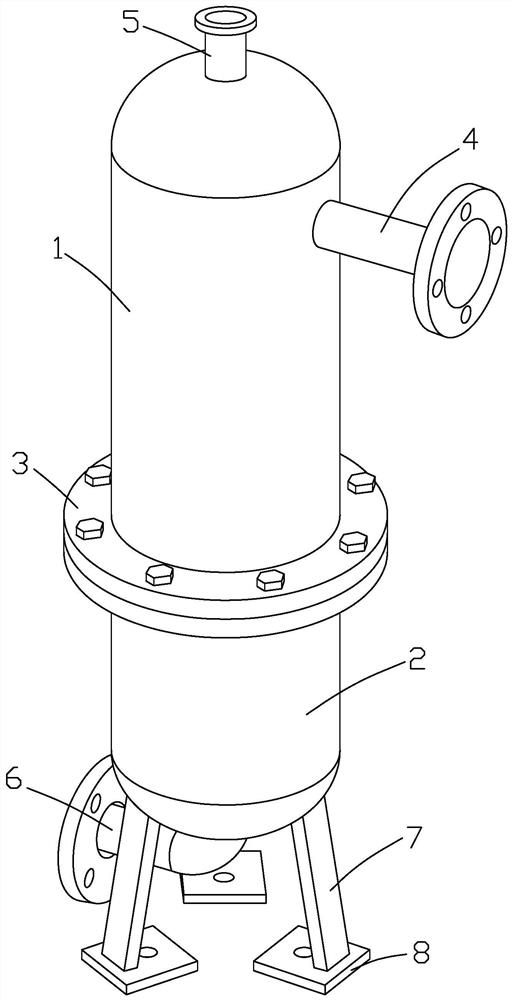

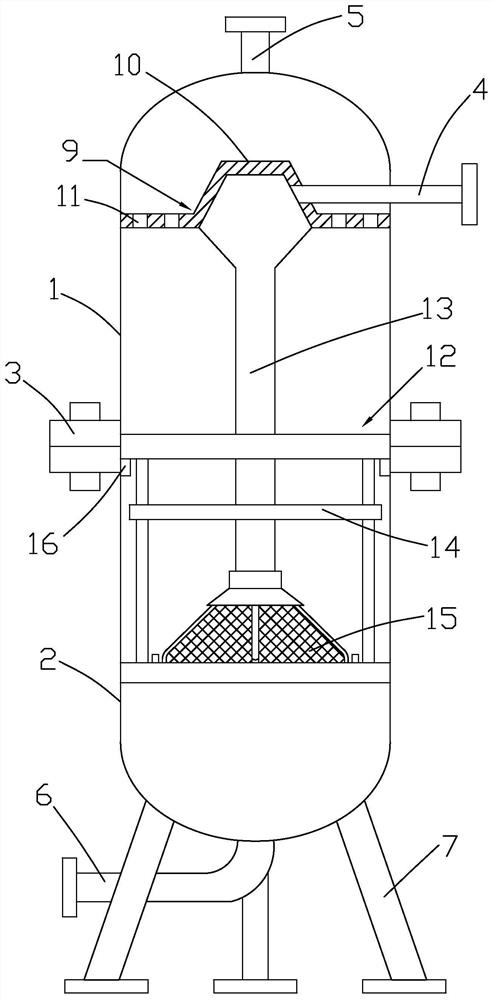

A method for manufacturing an oil-gas separator for a screw air compressor

ActiveCN113458725BRapid manufacturingImprove stabilityRotary piston pumpsRotary piston liquid enginesProcess engineeringAir compressor

The invention discloses a method for manufacturing an oil-gas separator for a screw air compressor, comprising the following steps: processing an upper cylinder, processing an air transmission mechanism, processing a lower cylinder, processing a separation mechanism, assembling the oil-gas separator, and treating oil and gas. The manufacturing method of the present invention has simple steps, which not only facilitates the rapid manufacturing and processing of the oil-gas separator, but also improves the stability and reliability of the assembly of the oil-gas separator, greatly improves the efficiency of oil-gas separation, and is beneficial to ensure the stable and reliable operation of the oil-gas separator. Work.

Owner:衢州亿诚机械有限公司

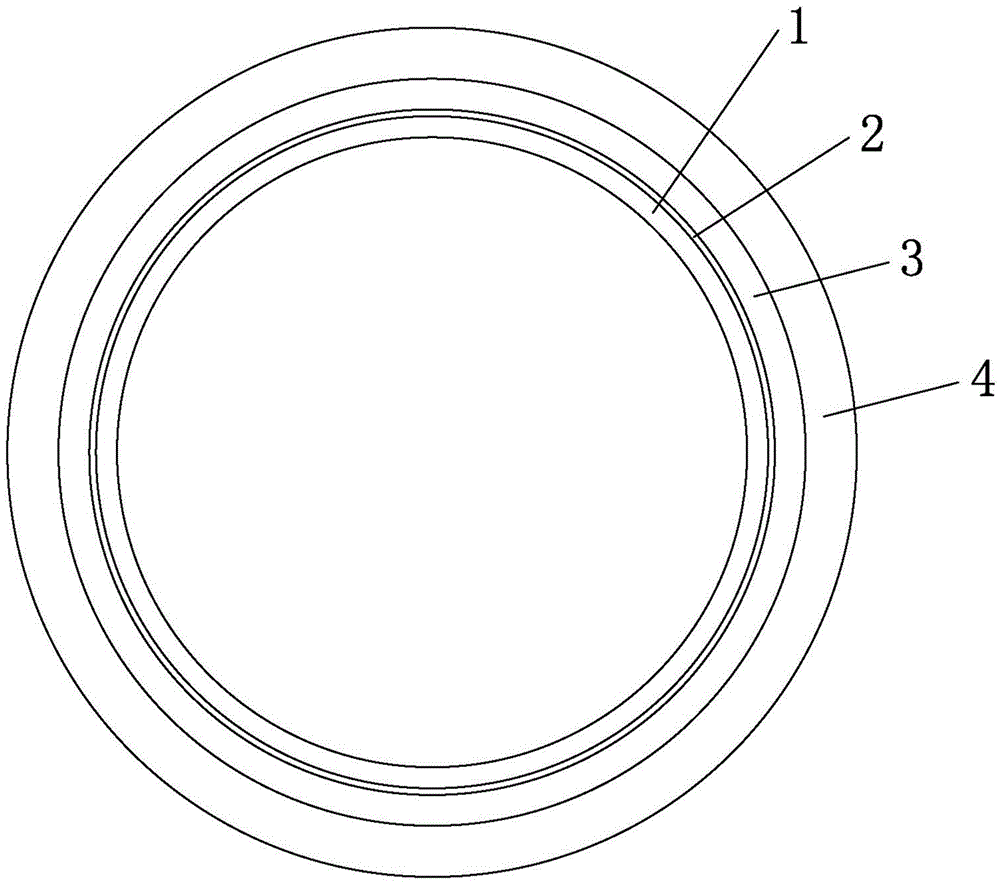

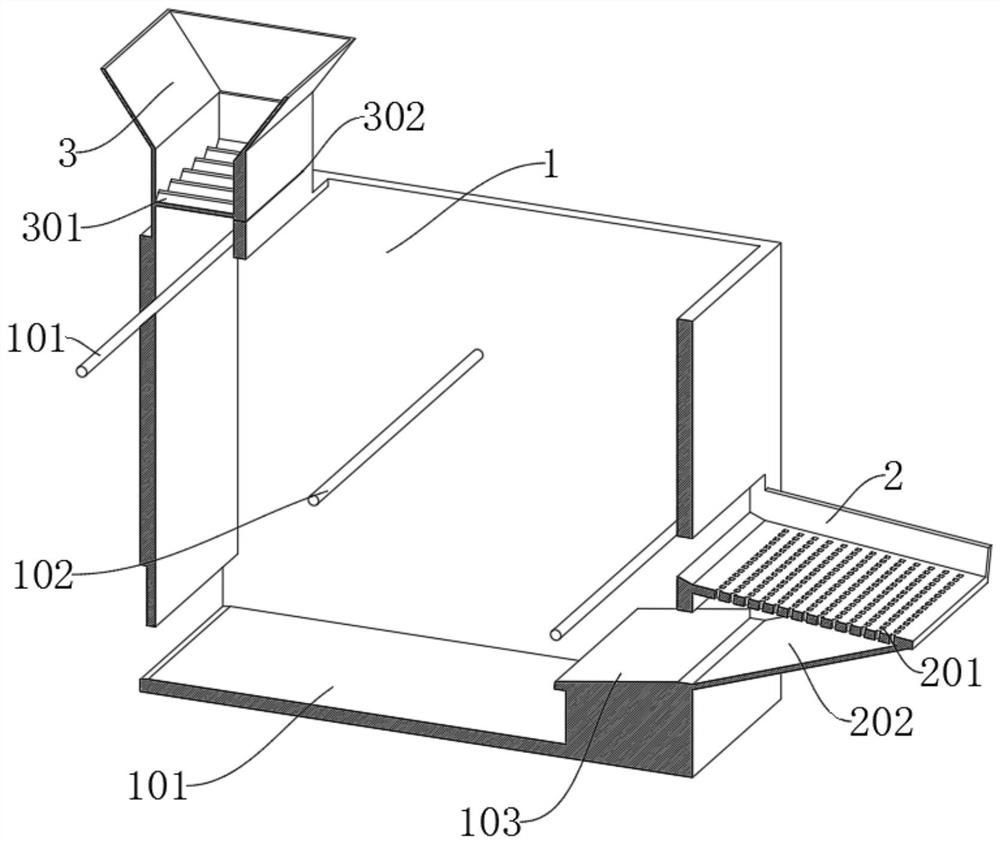

Gasket manufacturing method

The invention provides a gasket manufacturing method and relates to the technical field of the gasket manufacturing. The method comprises the steps: cutting a steel plate according to the width of a gasket by a plate shearing machine to form a narrow plate strip; processing the narrow plate strip by a lathe to make the narrow strip become a roll to form a spring-shaped gasket; and cutting and pressing the spring-shaped gasket in the axial direction of the spring-shaped gasket to form a ring gasket. The steel plate is cut by the plate shearing machine to form the narrow plate strip with the same width as the gasket, the narrow plate strip is processed by the lathe to form the spring-shaped gasket, and the spring-shaped gasket is cut and pressed in the axial direction of the spring-shaped gasket to form the ring gasket, so that the technological problems of low material utilization ratio, serious material waste, large manufacturing difficulties, time waste and effort waste in the gasketmanufacturing in the prior art are relieved, and the technologic effects of fast manufacturing of the gasket and high material utilization ratio are realized.

Owner:SHANDONG ELECTRIC POWER CONSTR NO 2

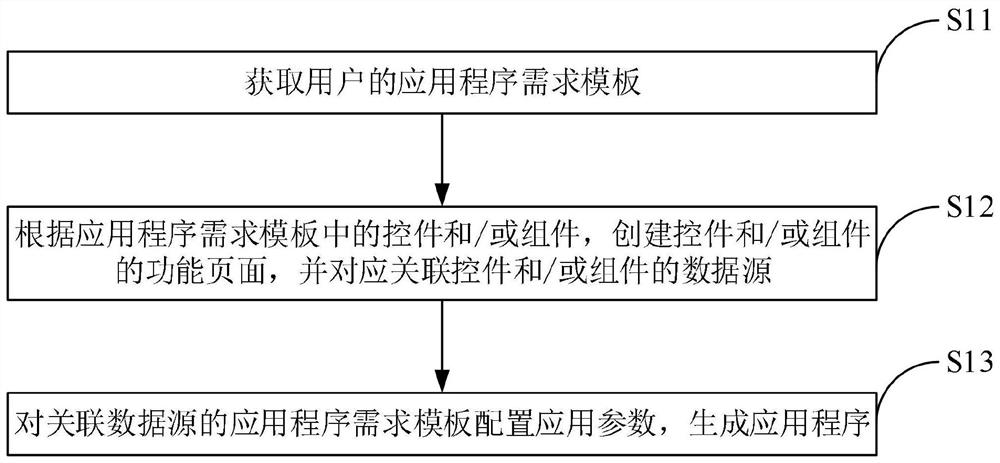

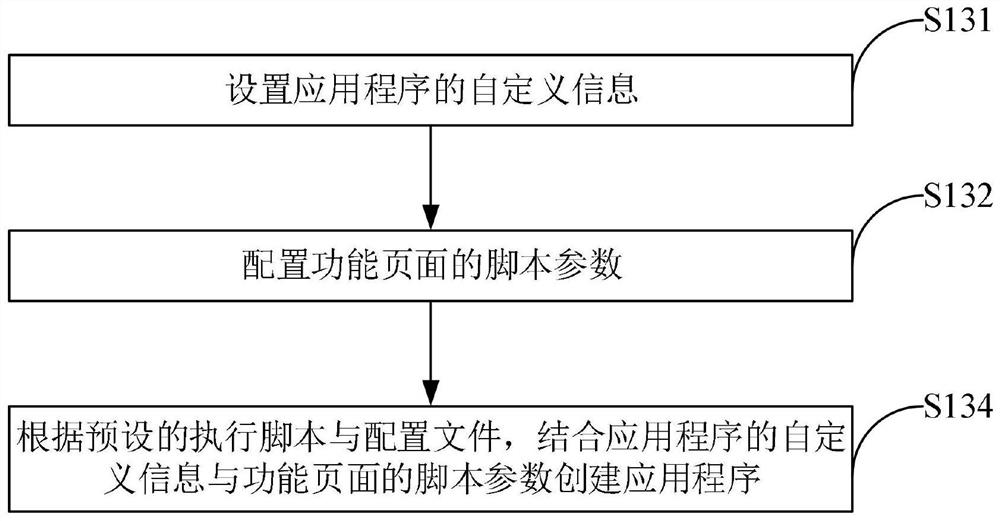

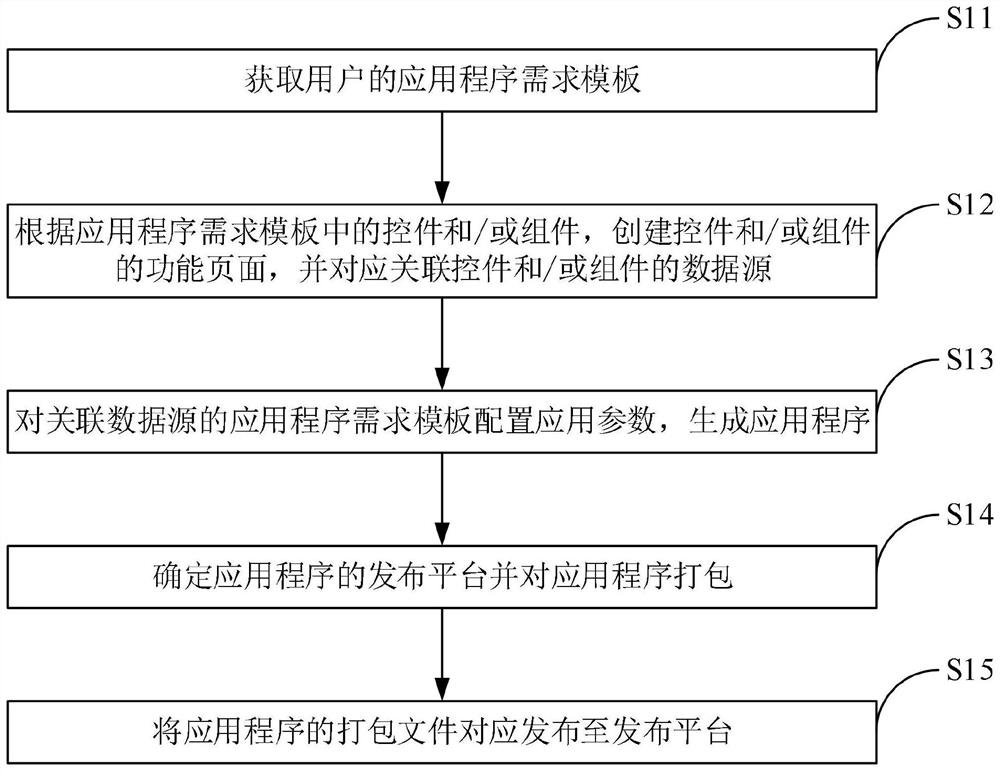

Method and device for automatically generating application program

PendingCN111813377ARapid manufacturingMeet the needs of rapid production applicationsVersion controlSoftware designProgramming languageGeneration process

The invention is suitable for the technical field, and provides a method and device for automatically generating an application program, and the method comprises the steps of obtaining an applicationprogram demand template of a user; according to a control and / or a component in the application program demand template, creating a function page of the control and / or the component, and correspondingly associating a data source of the control and / or the component; and configuring application parameters for the application program demand template associated with the data source, and generating anapplication program. According to the invention, the requirement of a user for quickly making applications can be met; a simple function required by a user can complete configuration and manufacturingof an application program through a preset application generation process, the whole process is generated through an automatic script, participation of research and development personnel and participation of energy experts are not needed, and the application program with high pertinence can be quickly generated only by one person through simple dragging and setting.

Owner:XINAO SHUNENG TECH CO LTD

Preparation method of led white light diode

Owner:CHANGZHOU GALAXY CENTURY MICROELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com