Mould used for injection molding and manufacture method for composite article

A technology of injection molding and manufacturing methods, applied in the direction of coating, etc., can solve the problems of easily damaged transfer sheets and easy softening of transfer sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

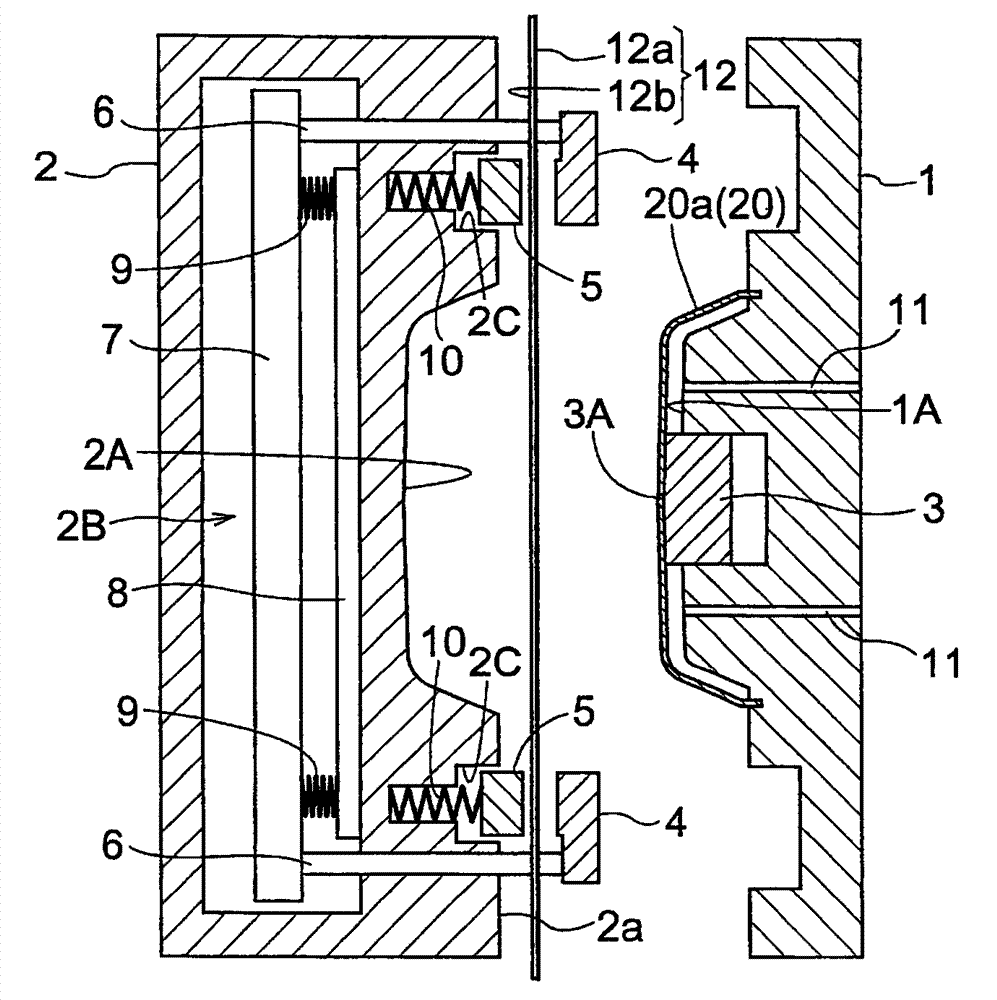

[0058] Figure 1 to Figure 7 All are diagrams showing a molding process of a composite product using the mold according to the present invention.

[0059] The resin molded article according to the present invention includes: a metal body 20 having a convex portion 20a; a decorative layer formed on the surface of the metal body 20; and a resin portion 30 formed on the metal body 20a. On the back side of the body 20, this resin molded product is manufactured through the following manufacturing steps.

[0060] [metal body]

[0061] The metal body 20 is, for example, a metal stamped plate having a convex portion 20a or the like. In order to facilitate the formation of the decorative layer, the surface of the metal body 20 is preliminarily subjected to surface treatment such as coating of an adhesive or pasted with a sheet that is easy to adhere to the decorative layer. In addition, in order to easily fix the injected resin, an adhesive layer is applied in advance on the back of...

no. 2 approach

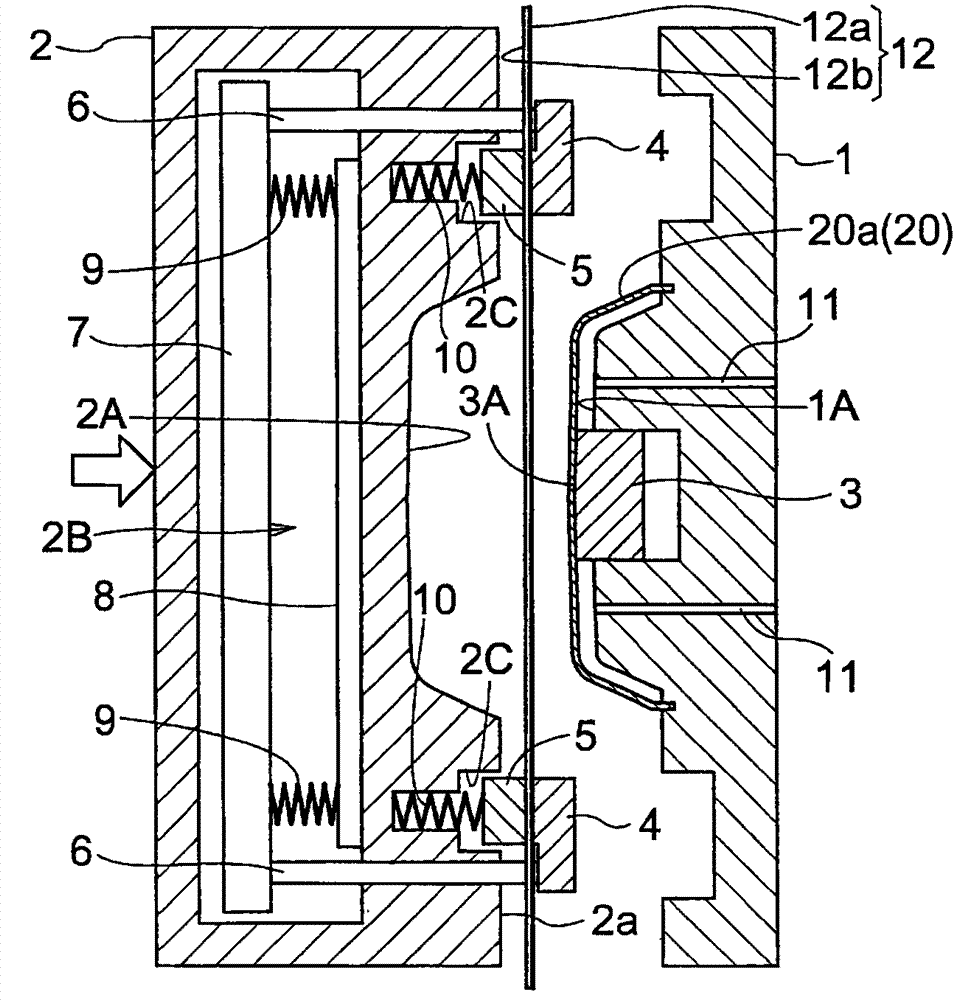

[0082] In this embodiment, only the configurations different from those of the first embodiment will be described, and the description of the same configurations will be omitted. Figure 8 is a diagram in which the transfer sheet 12 is positioned and held, Figure 9 It is a figure showing the middle of mold clamping, Figure 10 It is a figure which shows after mold clamping.

[0083] Such as Figure 8 As shown, in this embodiment, the first mold 1 is provided with a suction portion 13 for sucking the transfer sheet 12 around a portion of the cavity surface 1A for holding the metal body 20 . In addition, an O-ring 14 is arranged on the first mold 1 and the portion where the first holder 4 is recessed when the mold is closed.

[0084] [Processing steps for resin molding]

[0085] Such as Figure 8 As shown, after holding the transfer sheet 12 by clamping the transfer sheet 12 with the first clamping member 4 and the second clamping member 5, the transfer sheet 12 is heated ...

no. 3 approach

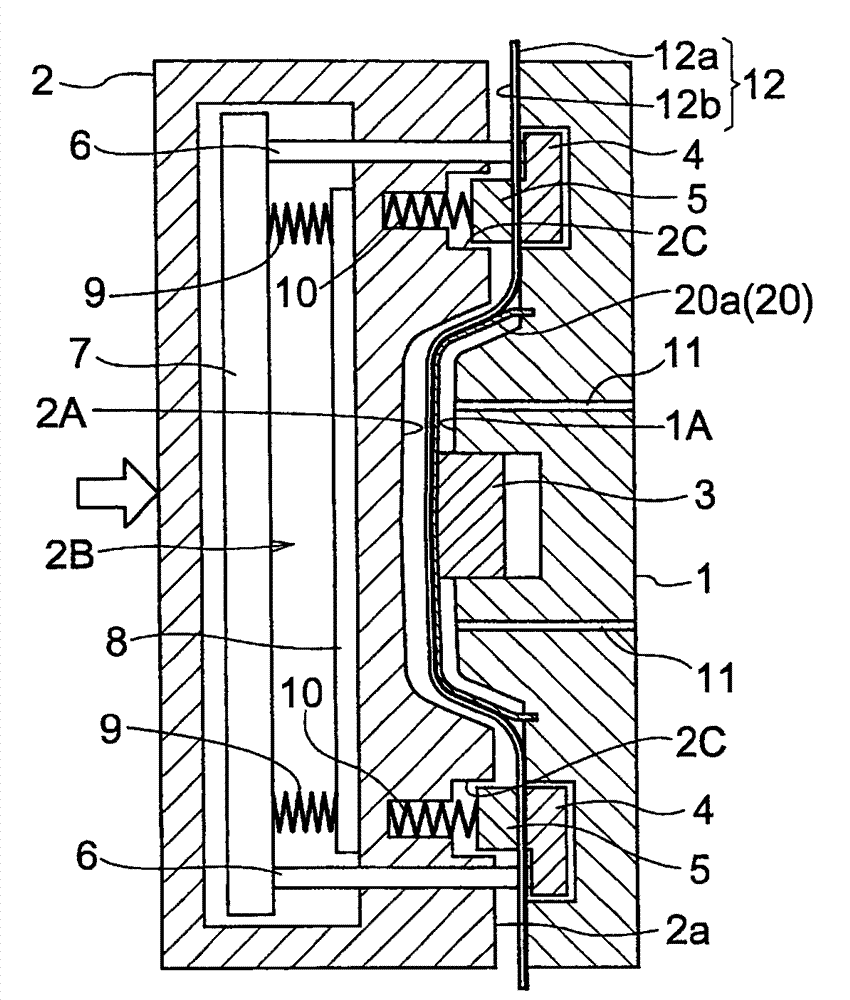

[0089] Figure 11 ~ Figure 13 A third embodiment of the present invention is shown. Such as Figure 11 As shown, in this embodiment, a slide mold 3 capable of moving relative to the first mold 1 along the clamping direction of the first mold 1 is provided inside the first mold 1, and the metal body 20 is disposed on the first mold 1. Slide mold3. The transfer sheet 12 is held along the molding surface 1 a of the first mold by a clip 15 that functions as a decorative sheet holding mechanism.

[0090] [Processing steps for resin molding]

[0091] Such as Figure 11 As shown, the slide mold 3 is held at a position receding from the molding surface 1 a of the first mold 1 , and the metal body 20 is disposed on the end surface 3A of the slide mold 3 . The transfer sheet 12 is disposed on the molding surface 1a of the first mold.

[0092] Next, the transfer sheet 12 is heated with a heater or the like as necessary, and then, as Figure 12 As shown, the slide mold 3 is advance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com