Manufacturing method of cam component and its application in textile machinery

A production method and component technology, which are applied in the production of precision cam components in textile machinery and in the field of production of cam components, can solve the problems of high cost, high resistance to sintering and compactness, time-consuming and high cost, and achieve fast and fast manufacturing with less Adhesion, effect of high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

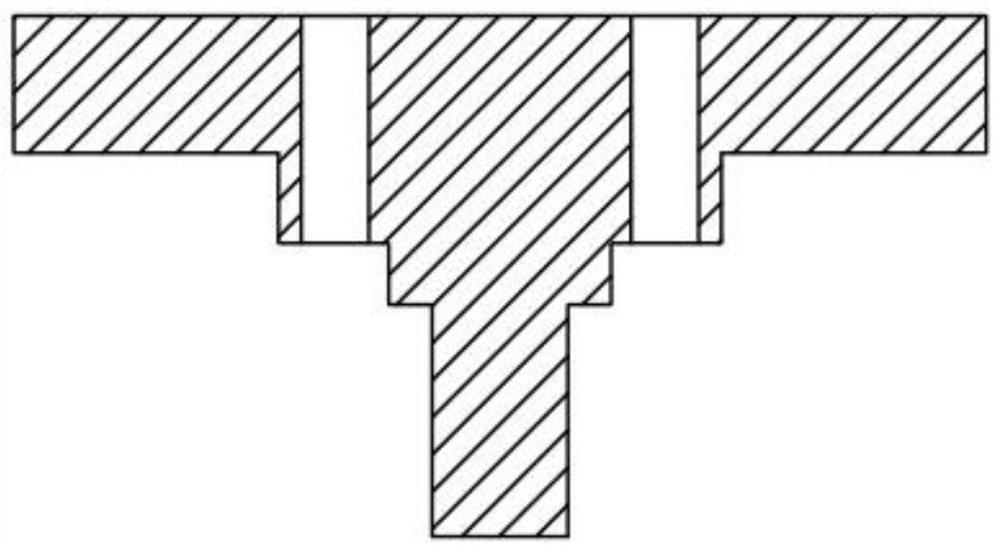

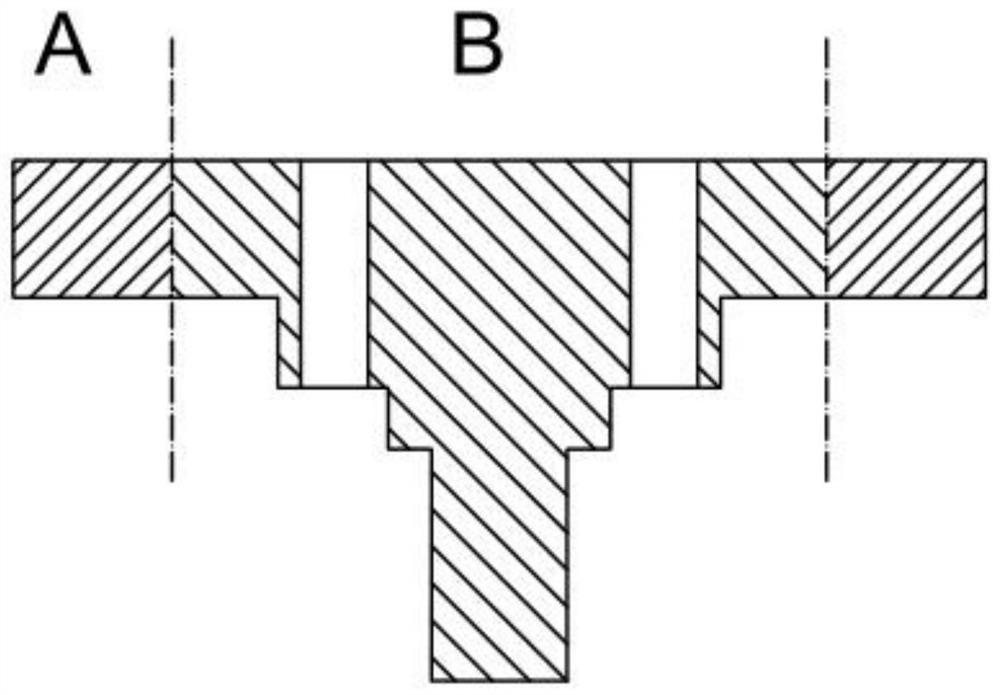

[0032] see Figure 1-Figure 5 , a method for manufacturing a cam component in this embodiment at least includes the following steps:

[0033] 1. Disassemble the overall part model of the cam component, and split the overall part model of the cam component into a wheel edge part A with a relatively simple shape and a shaft core part B with a relatively complex shape;

[0034] 2. The above-mentioned wheel edge part A of the cam part is produced by the molding and sintering process in the powder metallurgy process, specifically: select the wheel edge part metal powder according to the wheel edge part material, directly put the wheel edge part metal powder into the pressing mold, or put The metal powder at the wheel edge is mixed with a binder with a mass content not higher than 6%, and then loaded into a pressing mold, and pressure is applied to the pressing mold to compact the metal powder at the wheel edge into a powder compact, and the powder compact is demoulded Then put it ...

Embodiment 2

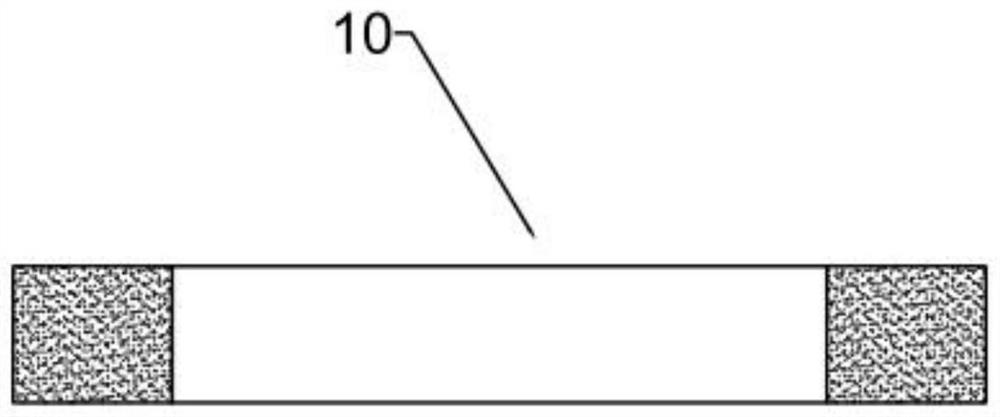

[0041] This embodiment is a further improvement on Embodiment 1. In this embodiment, in step 3, the rim portion cavity 31 is configured to be able to squeeze the sintered rim portion finished product 10 so that the sintered The material of the finished wheel edge part 10 produces a certain degree of flow and compression. The advantage of this solution is that it can reduce the requirements for molds and equipment when the sintered wheel edge part product 10 is prepared by the molding and sintering process, and the pressing pressure can be appropriately reduced. , and can be sintered in batches in the sintering furnace without hot pressing. When the sintered wheel edge product 10 is not enough to meet the compactness requirement by using the molding sintering process, the sintered wheel edge product 10 is implemented through the wheel edge cavity 31. Extrusion causes the material of the finished sintered wheel edge part 10 to flow and compress to a certain extent to achieve the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com