Optical instrument having a stabilization element for mounting and adjusting an optical assembly in a holder, and mounting method for the stabilization element

A technology of optical components and optical instruments, applied in the field of optical instruments, can solve problems such as attenuation, lack of plastic tolerance quality, unstable vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

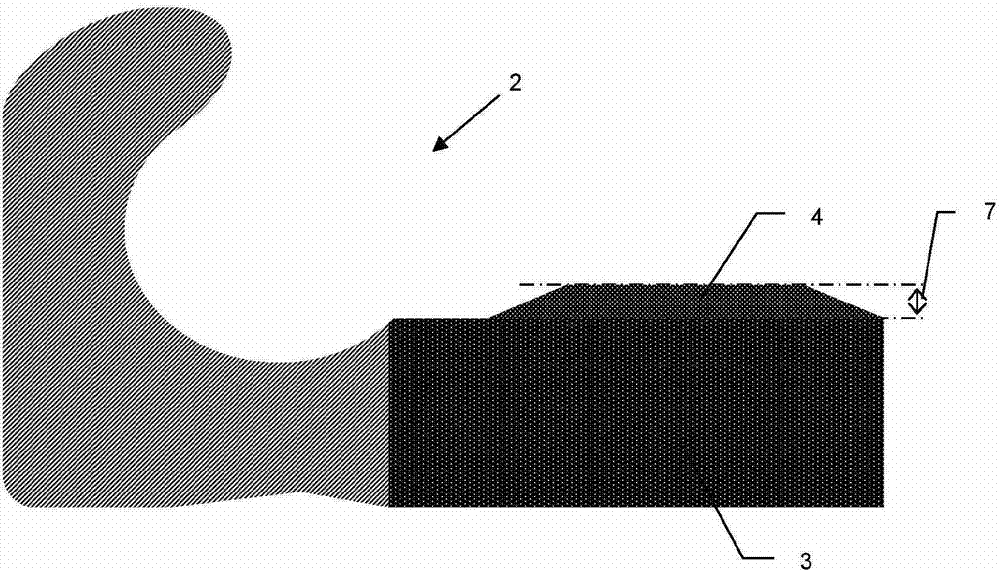

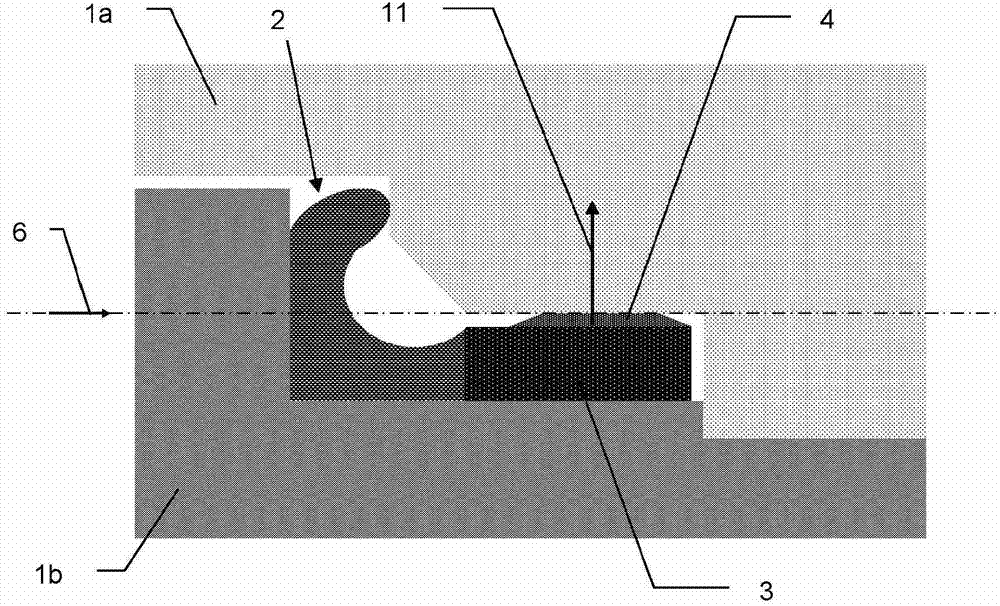

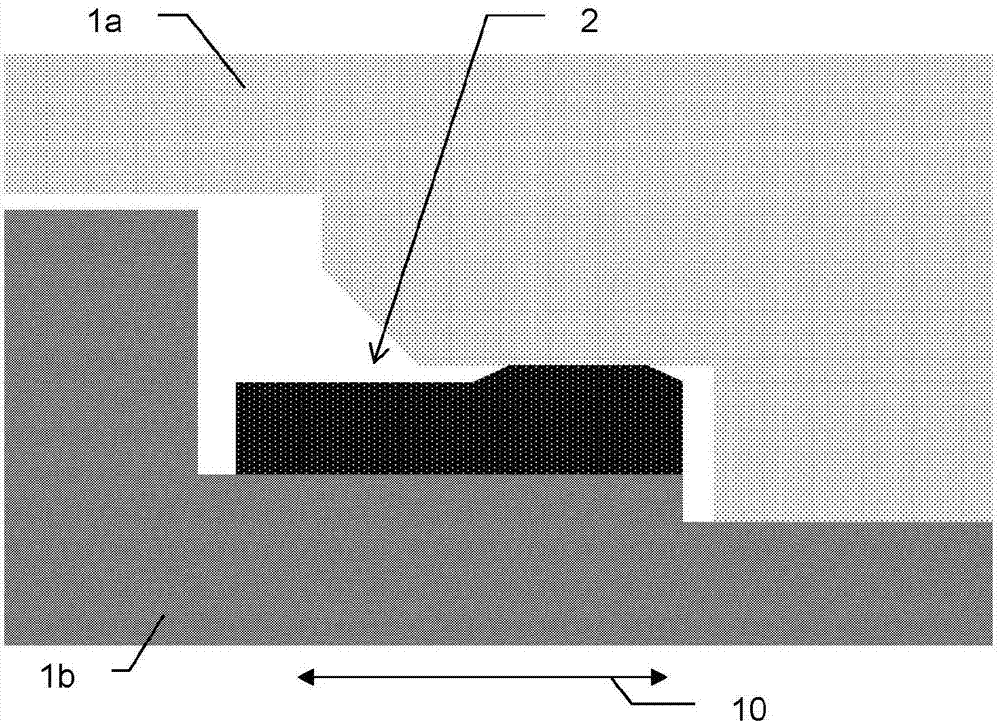

[0039] figure 1 The stabilizing element 2 according to the invention for mounting an optical component in a holder is shown in section. In this case, the stabilizing part comprises a stabilizing element 3 with a deforming element 4 . This deforming element also comprises a compression zone 7 in which the deforming element 4 deforms during mounting of the stabilizing part 2 in the optical instrument, but does not deform beyond said compressing zone.

[0040] The stabilizing element 3 with the deformation element 4 is thicker than the width of the gap that exists between the two precisely manufactured parts when they are connected to each other in the desired manner. By compressing the stabilizing element 3 , compressive stresses are generated therein which lead to plastic deformation of the deforming element 4 .

[0041] The deformation is in this case limited to a tolerance range in which the elastic compressive stress remains approximately constant in the production materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com