3D printing head for continuous-fiber-reinforced intelligent composite material and use method of 3D printing head

A continuous fiber and printing head technology, applied in the field of continuous fiber reinforced intelligent composite material 3D printing head, can solve the problems of lack of utilization form, limit the development of 3D printing technology, and find no related devices for continuous fiber reinforced composite material 3D printing, and achieve The effect of rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings.

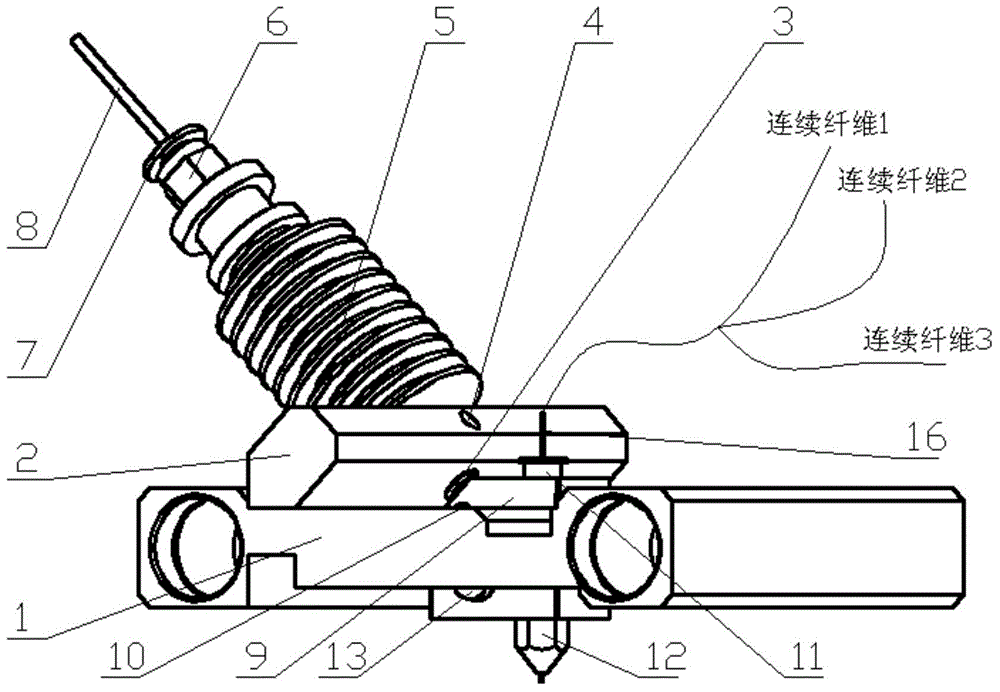

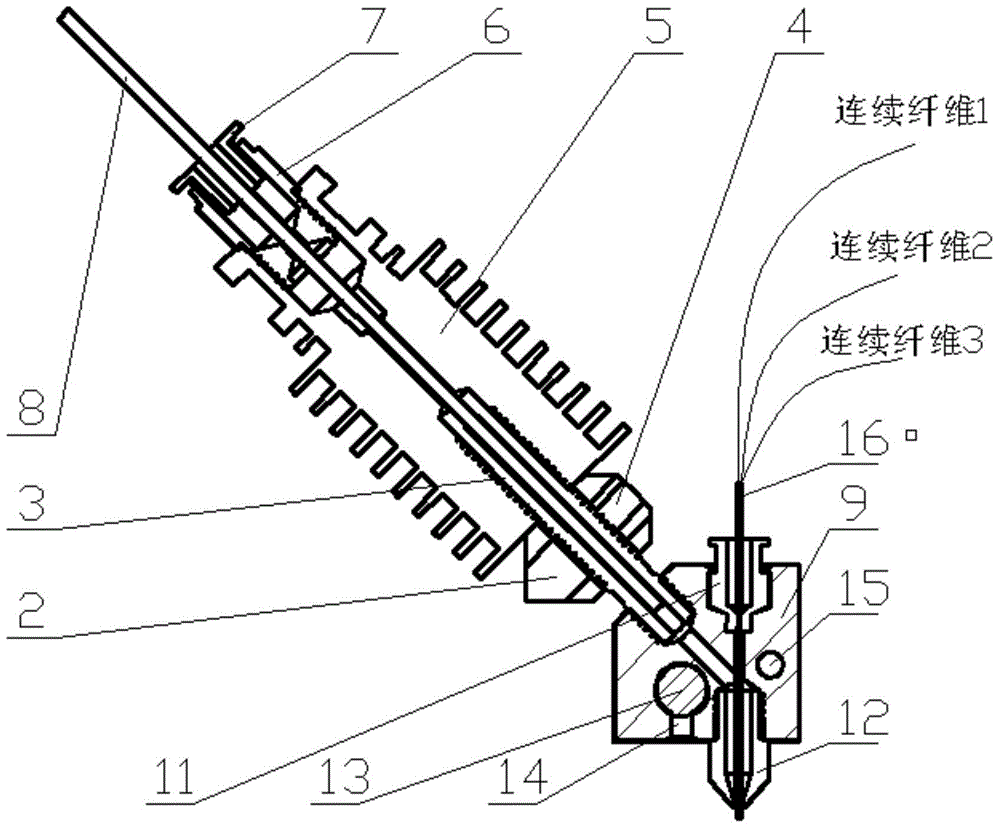

[0022] refer to figure 1 , a continuous fiber reinforced intelligent composite material 3D printing head, comprising a 3D printing head support 1, the 3D printing head support 1 is connected with the 3D printing head truss 2, the middle of the 3D printing head truss 2 is connected to the throat 3, and the truss set screw 4 Fasten the throat 3 to the truss 2 of the 3D printing head. A first inner channel is formed with the throat pipe 3, and the thermoplastic matrix material 8 passes through the first inner channel;

[0023] refer to figure 2 , the heating block set screw 10 fastens the throat pipe 3 on the heating block 9, and the heating block 9 is connected with a needle tube 11, a copper nozzle 12, a heating tube 13, a thermal sensor 15, and the heating tube set screw 14 fixes the heating tube 13 is fastened on the heating block 9, the needle tube 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com