Seamless table tennis ball with skeleton and manufacturing technology thereof

A manufacturing process, table tennis technology, applied in the field of seamless table tennis and its manufacturing process, can solve the problems of many production steps, time-consuming, easy damage, etc., to achieve the effect of preventing damage, less process steps, and fast manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

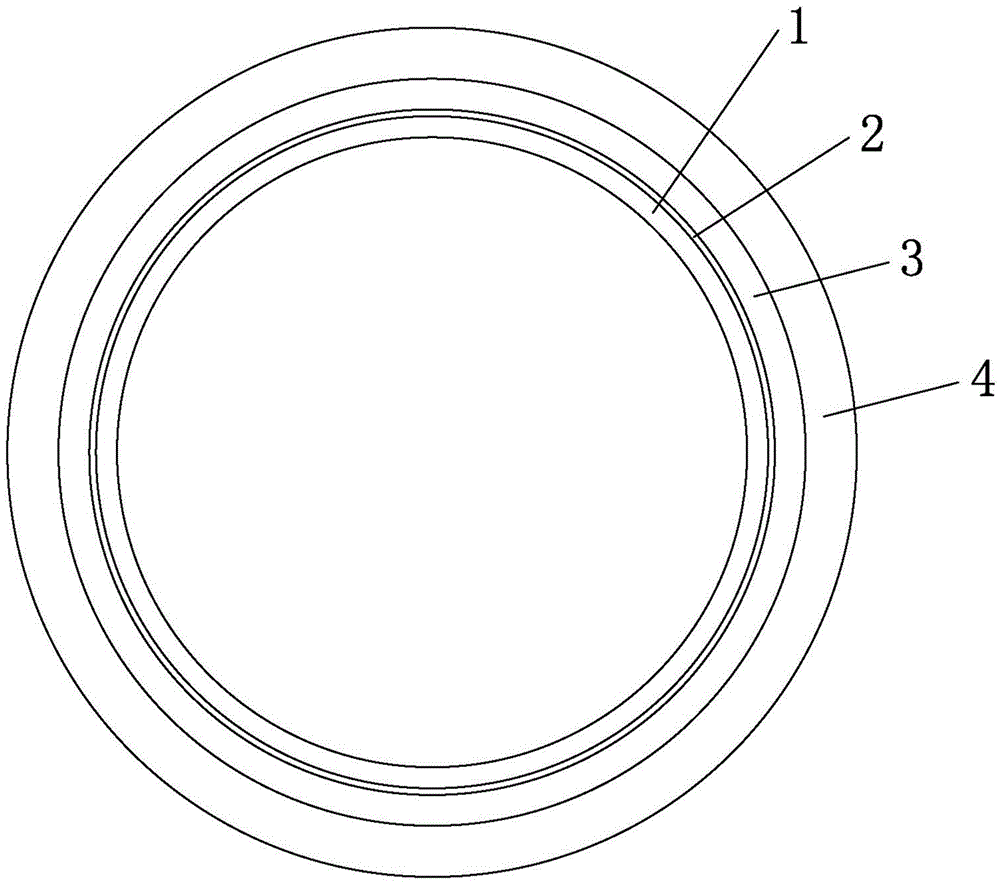

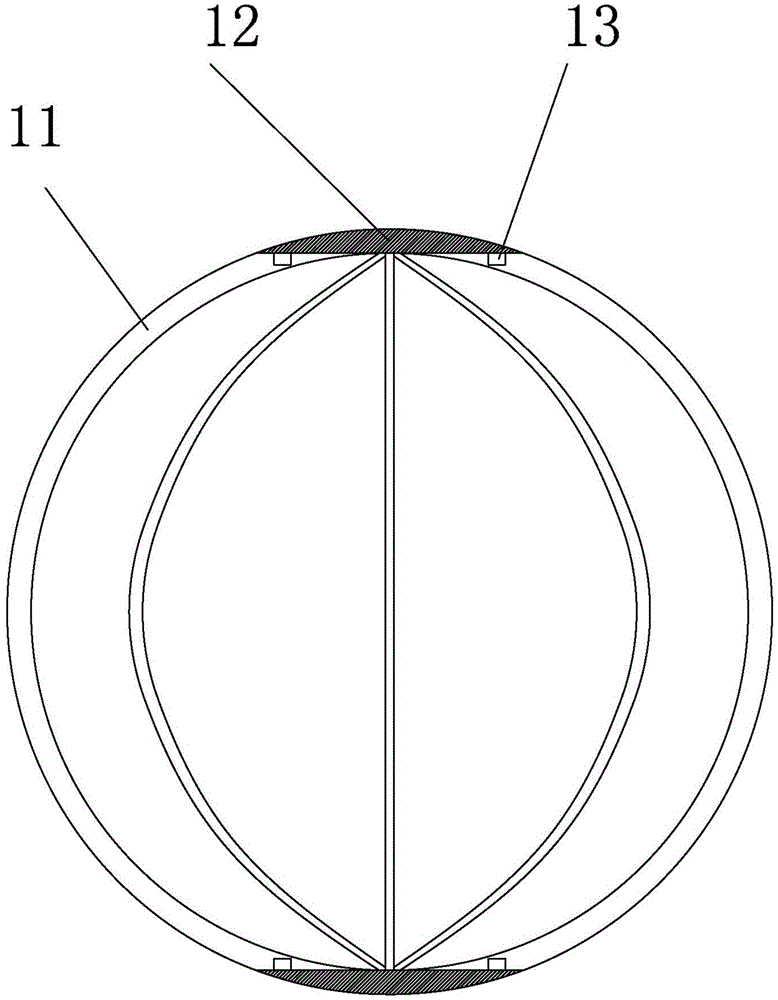

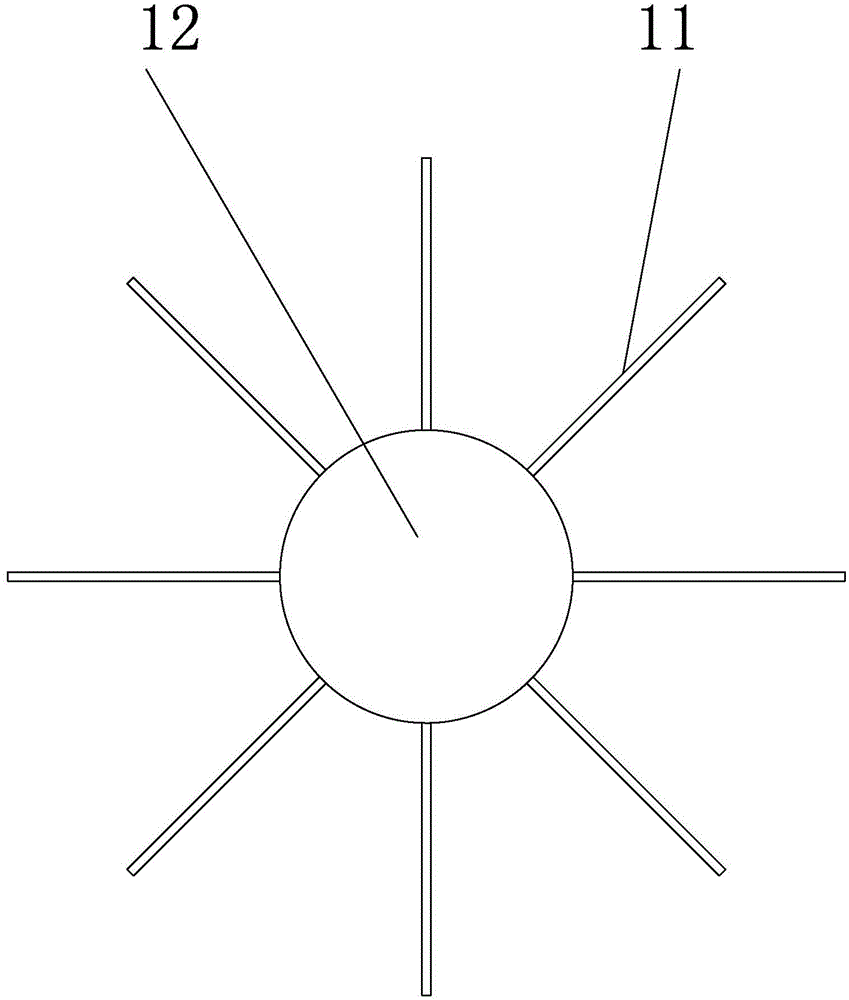

[0025] The first purpose of the present invention is to provide a seamless table tennis ball with a skeleton. The shell of the seamless table tennis ball with a skeleton includes arc-shaped meridian bones 11, and a plurality of meridian bones 11 are surrounded into a ball shape. The two ends of the warp bone 11 are connected into one by the top cover 12 to form an elastic spherical skeleton 1, the skeleton 1 is provided with a fine mesh layer 2 integrated with the skeleton, the fine mesh layer is provided with an adhesive layer 3, and the adhesive layer is outer A PVC spherical shell 4 integrally formed by injection molding is provided.

[0026] As a preferred embodiment of the present invention, the thickness of the warp bone in the radial direction of the table tennis ball is one-fifth of that of the PVC spherical shell of the table tennis ball.

[0027] As a preferred embodiment of the present invention, both ends of the above-mentioned meridian bone 11 are provided with gr...

Embodiment 2

[0029] Seamless table tennis ball manufacturing process with skeleton. The steps are as follows:

[0030] The first step is bone building, using a 3D printer or molding to make the meridian bone 11 and the top cover 12, and assemble it into an elastic spherical skeleton 1,

[0031] The second step is spinning, using an extrusion spinneret to spray and solidify the hot-melt filaments on the skeleton 1, spraying multiple times and forming a fine mesh layer attached to the skeleton 1 and integrated with the skeleton 2;

[0032] The third step is to spray the mixed glue, ultrasonically crush the hot-melt PVC sheet into ultra-fine PVC material powder, mix the hot-melt glue powder and PVC material powder according to the volume ratio of 1:1-1:2, and add it to the ordinary Mix the glue in the glue and stir evenly to form a mixed glue, and then apply the mixed glue and form a partial penetration into the fine mesh layer to transition the mixed glue layer 3;

[0033] The fourth step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com