A partial discharge suppression method at the flange of a gis/gil support insulator

A technology supporting insulators and partial discharges, applied in insulators, processing data acquisition/processing, circuits, etc., can solve problems such as difficulty in hindering the movement of micron-level particles, and achieve high-precision manufacturing, high interface bonding strength, and compatibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Example 1: 110kV Disc Support Insulator

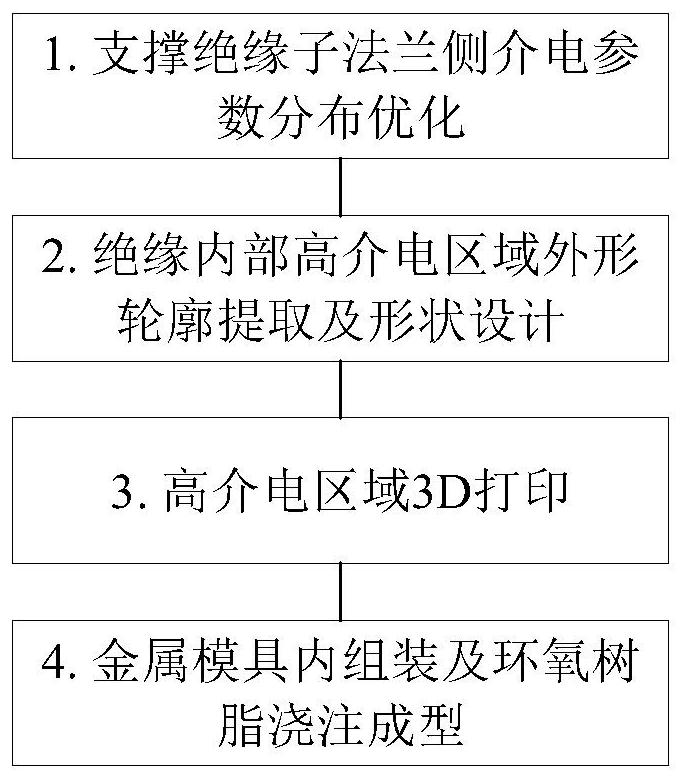

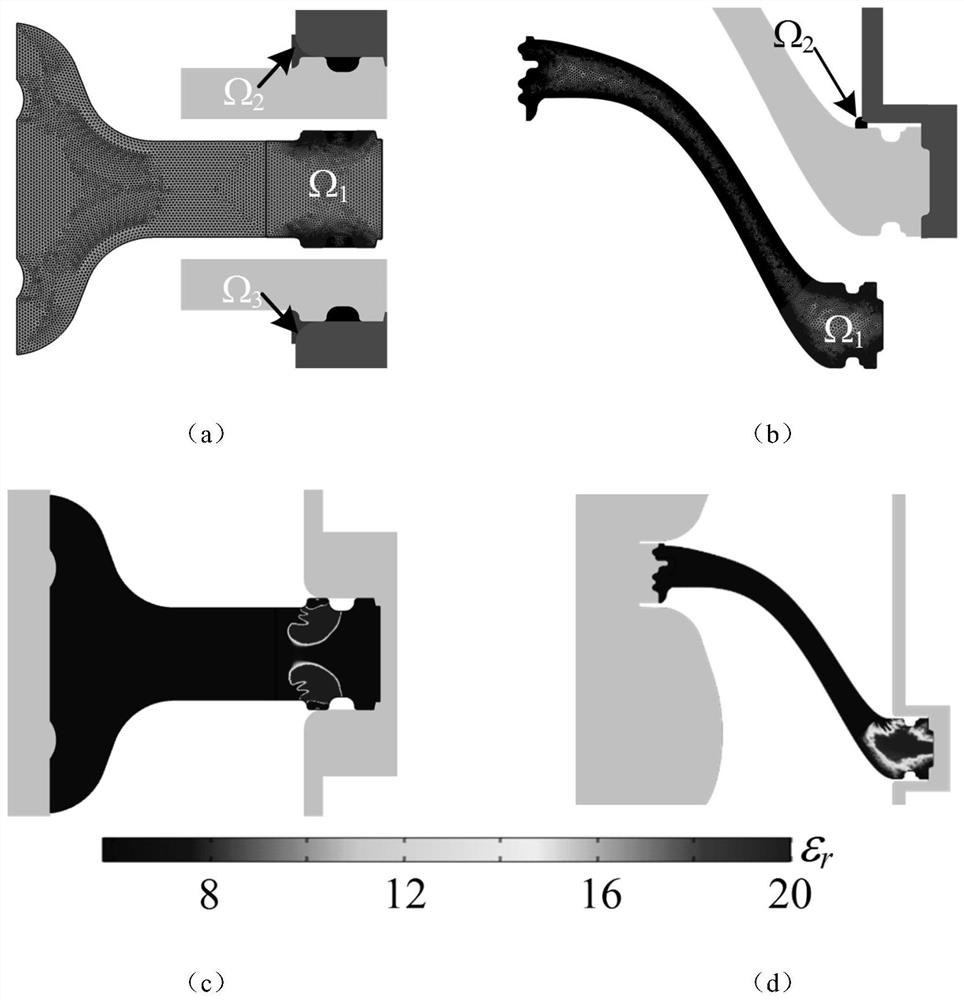

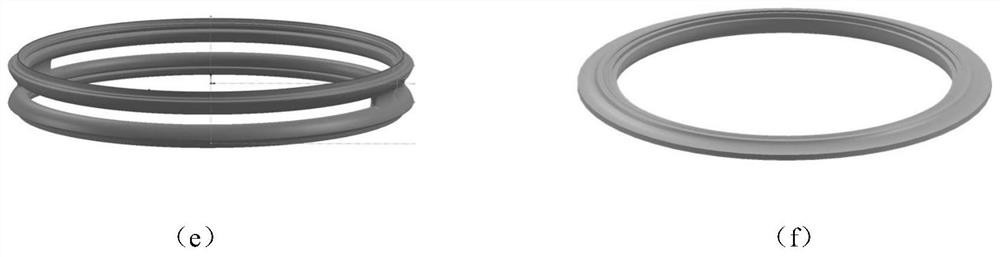

[0077] 1) Optimization of the dielectric parameter distribution on the flange side of the supporting insulator

[0078] The two-dimensional axisymmetric structure of the 110kV disc-supported insulator is as follows: figure 2 As shown in (a), taking the optimized dielectric constant as an example, the root Ω of the supporting insulator 1 The area is the design feasible area, and the area indicated by the arrow is the optimization target area Ω 2 and Ω 3 , the mathematical description of the optimization problem is as in Equation 1, and the design variable is the design feasible region Ω 1 The permittivity in any grid in the inner, optimization objective is divided into two parts, f 1 is the electric field integral term, which is used to reduce the optimization target area Ω 2 and Ω 3 The value of the electric field in the . C ref1 and C ref2 respectively f 1 The normalization parameters of the two optimization componen...

Embodiment 2

[0089] Example 2: 110kV Basin Support Insulator

[0090] 1) Optimization of the dielectric parameter distribution on the flange side of the supporting insulator

[0091] The 110kV disk-type supporting insulator is taken as an example to optimize the dielectric constant. 1 The area is the design feasible area, and the area indicated by the arrow is the optimization target area Ω 2 and Ω 3 , the mathematical description of the optimization problem is shown in Equation 3, and the design variable is the design feasible region Ω 1 The permittivity in any grid in the inner, optimization objective is divided into two parts, f 1 is the electric field integral term, which is used to reduce the optimization target area Ω 2 and Ω 3 The value of the electric field in the . C ref1 and C ref2 respectively f 1 The normalization parameters of the two optimization components in the middle are so that the value obtained in the initial calculation process is 1, thereby improving the con...

Embodiment 3

[0102] Example 3: 550kV Basin Support Insulator

[0103] 1) Optimization of the dielectric parameter distribution on the flange side of the supporting insulator

[0104] The two-dimensional axisymmetric structure of the 550kV basin support insulator is as follows: figure 2 As shown in (b), taking the optimized dielectric constant as an example, the root Ω of the supporting insulator 1 The area is the design feasible area, and the area indicated by the arrow is the optimization target area Ω 2 , the mathematical description of the optimization problem is shown in Equation 5, and the design variable is the design feasible region Ω 1 The permittivity in any grid in the inner, optimization objective is divided into two parts, f 1 is the electric field integral term, which is used to reduce the optimization target area Ω 2 and Ω 3 The value of the electric field in the . C ref for f 1 The normalization parameters of the two optimization components in the middle are so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com