Use method of angle platform for numerical control machining

An angle table and angle technology, applied in the field of mold manufacturing, can solve the problems of large mold volume, high processing cost, and long service life of the crane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

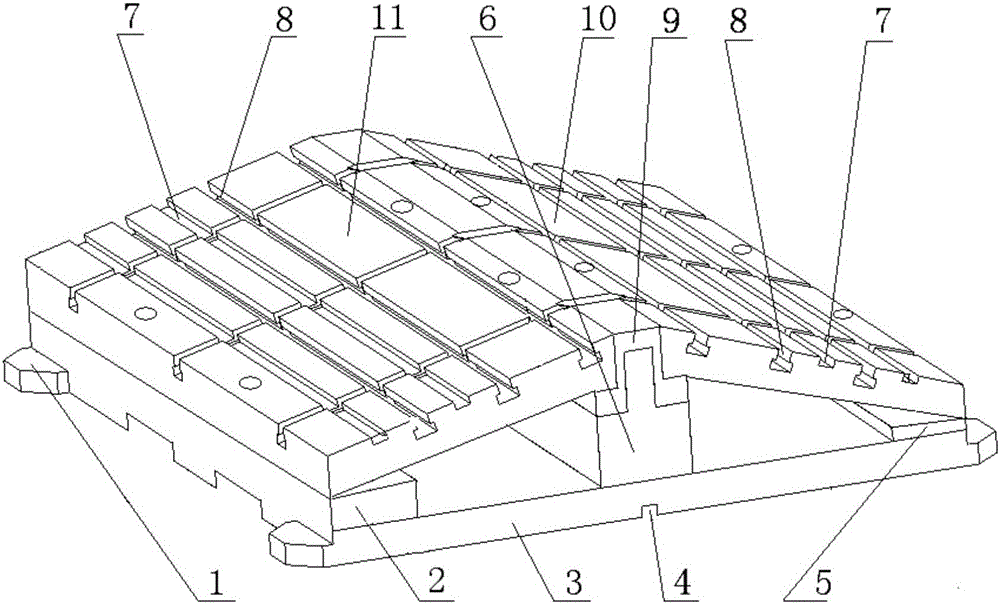

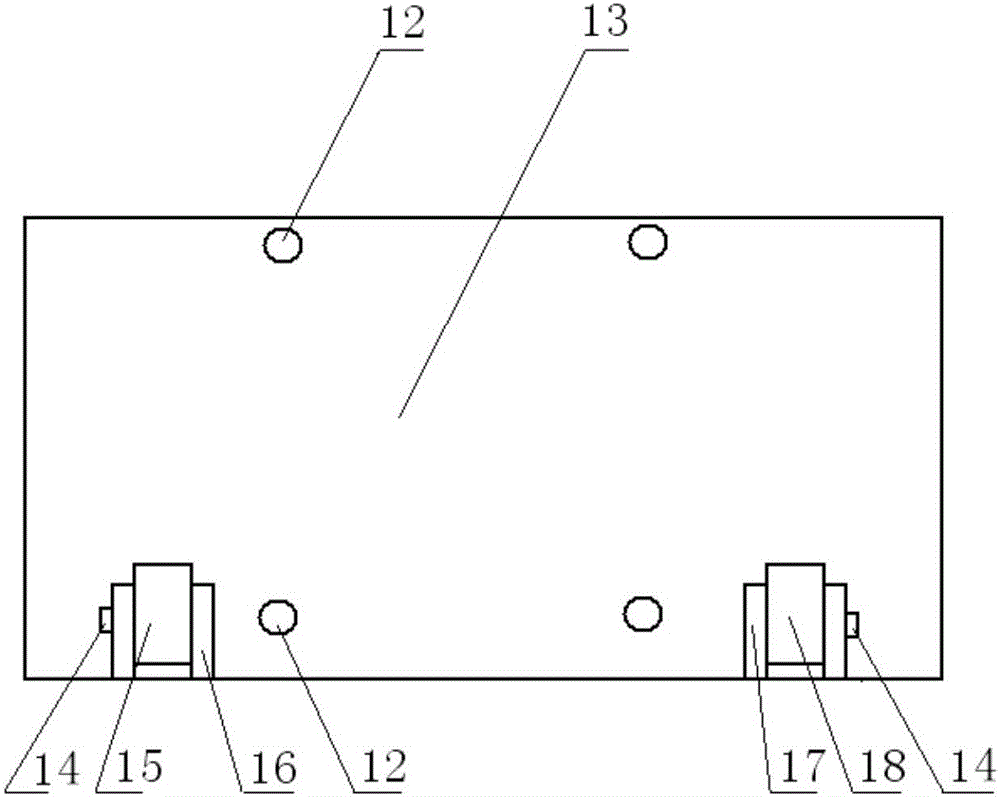

[0012] like figure 1 , figure 2 As shown, the angle table for CNC machining of automobile molds includes a base plate, a first inclined plate 11, a second inclined plate 10 and an inclined plate support seat assembly. The base plate has a base plate body 3, a base plate first support bar 2 and a base plate The second support bar 5, the base plate body 3 is a cuboid, the four corners of the base plate body 3 have base plate bosses 1, the first support bar 2 of the base plate is a long bar with a rectangular cross section, and the second support bar 5 of the base plate is The cross section is a rectangular strip, the first support bar 2 of the base plate and the second support bar 5 of the base plate are respectively located at the edge of the upper surface of the base plate body 3, and the inclined plate support seat assembly is placed in the middle of the upper surface of the base plate body 3, The first inclined plate 11 and the second inclined plate 10 are of the same stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com