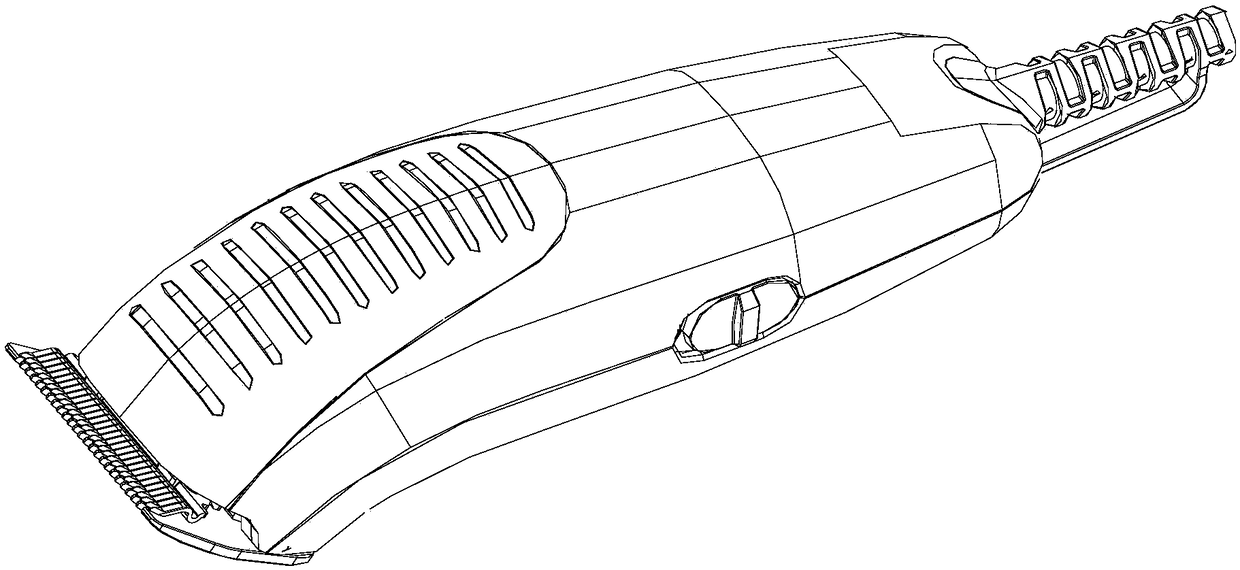

Electric clippers with detachable fixed and movable blades

A technology of electric clippers and fixed knives, applied in metal processing, etc., can solve problems such as motor failure to start, insufficient driving force, loss of shearing function, etc., and achieve the effects of enhanced flushing effect, convenient operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

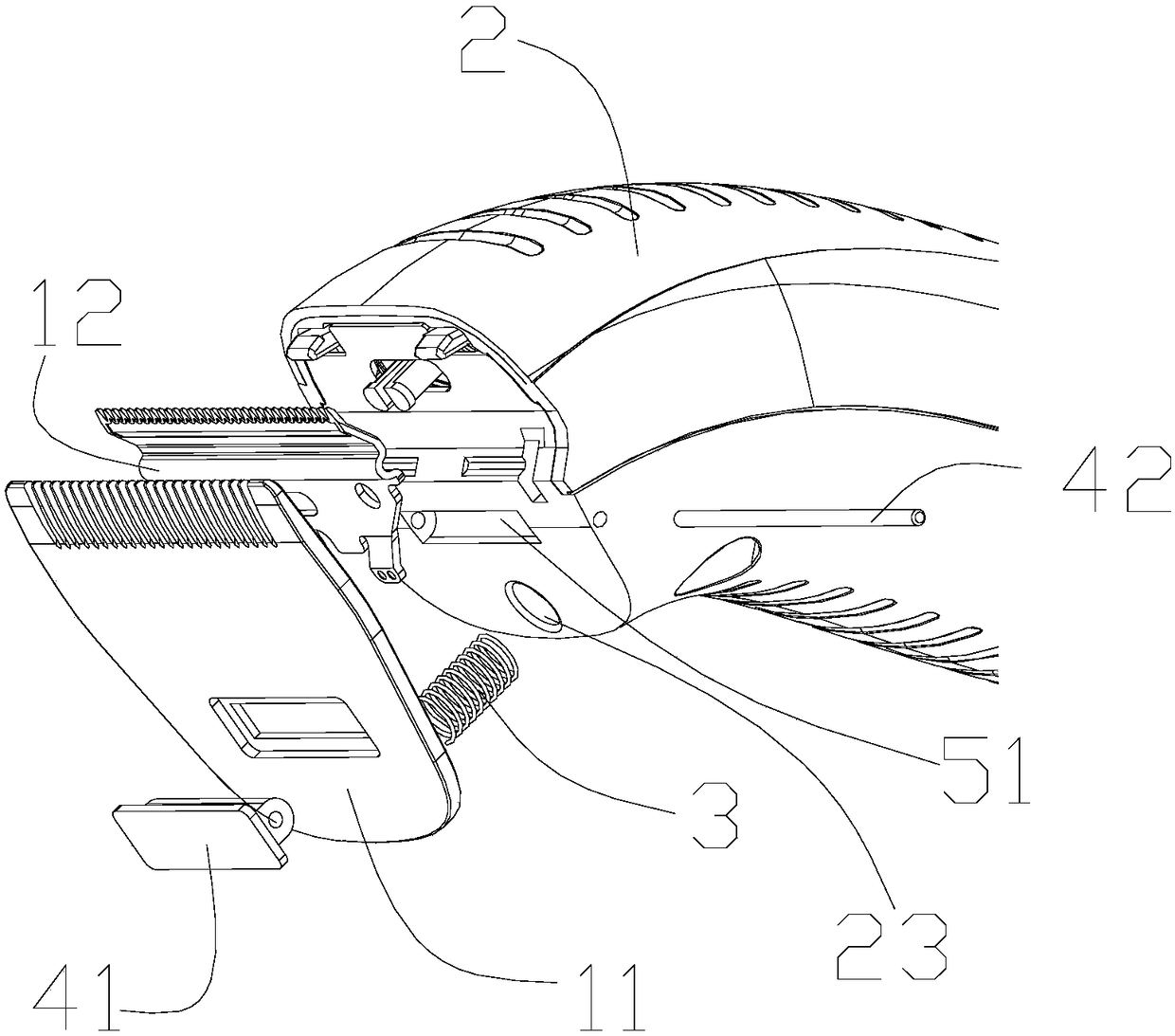

[0026] This embodiment provides an electric clipper in which the moving knife does not move and the fixed knife can be pried away from the moving knife.

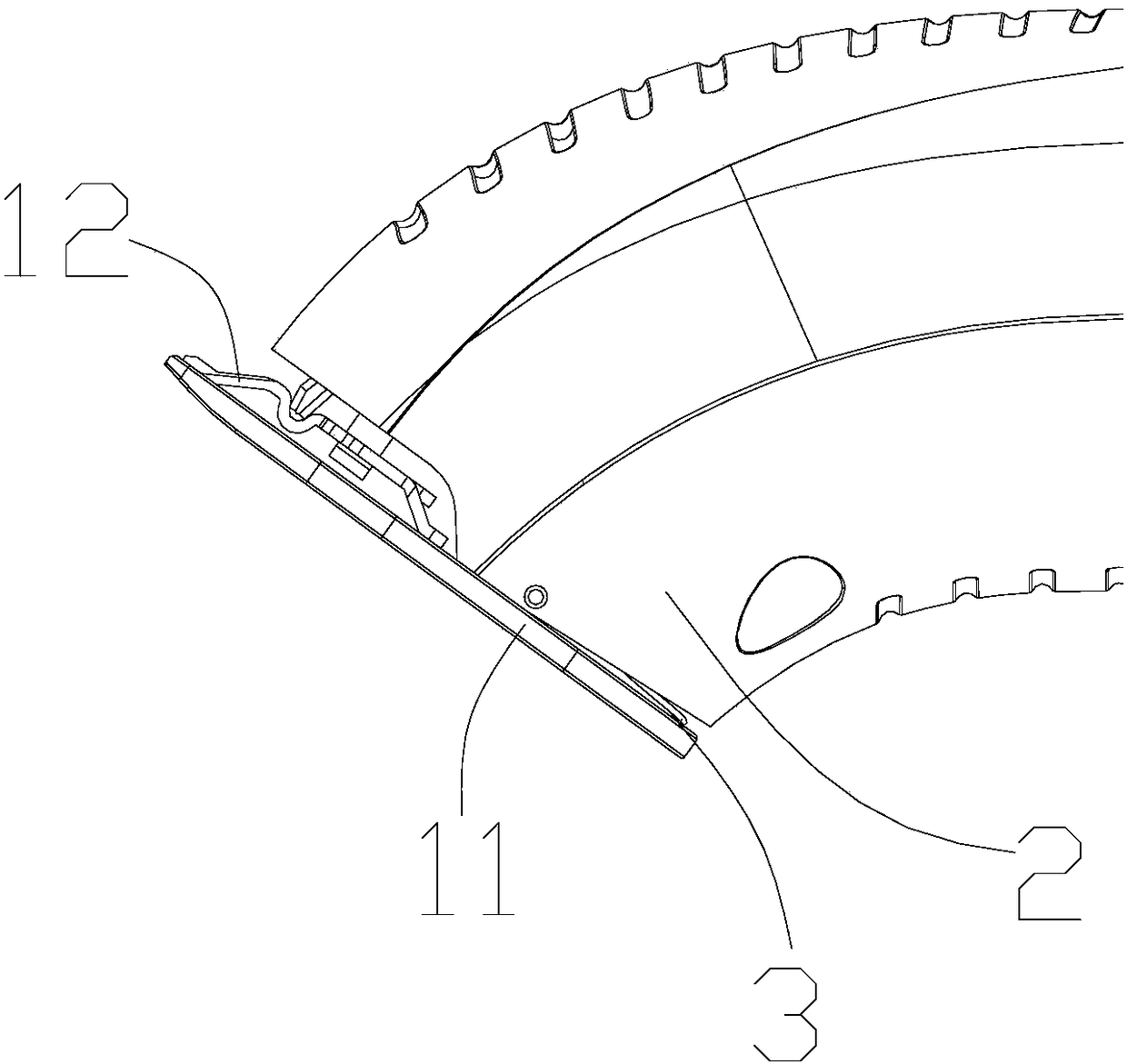

[0027] Such as Figure 2-5 As shown, the blade separation device is a spring 3, which is arranged between the rear end of the fixed knife 11 and the knife head installation part. Specifically, the cutter head mounting part is provided with a positioning hole 23 for accommodating and fixing the spring 3, one end of the spring 3 abuts against the inner surface of the rear end of the fixed knife 11, and the other end abuts against the inner surface of the rear end of the fixed knife 11. Position the bottom of hole 23. When the rear end of the fixed knife is not pressed, the spring 3 is not pressed and is in a free state. At this time, there is a gap between the rear end of the fixed knife 11 and the cutter head mounting part, so that the rear end of the fixed knife 11 is pressed become possible.

[0028] The cutter head also...

Embodiment 2

[0034] This embodiment provides an electric clipper in which the fixed knife does not move and the movable knife is separated from the fixed knife by pressing.

[0035] Such as Figure 6-8 As shown, the fixed knife 110 is fixed on the knife head installation part by a screw 80, and a pressure knife member 60 is provided between the knife head installation part and the moving knife 120 to hold the moving knife The knife 120 is pressed against the fixed knife 110 .

[0036] The blade separation device includes a button 410 and a shrapnel 420 . The shrapnel 420 is in the shape of a strip, which is arranged between the fixed knife 110 and the movable knife 120 in a direction perpendicular to the edge of the knife tooth of the movable knife 120 , and one end thereof is located at the edge of the knife tooth of the movable knife 120 Near the edge and in contact with the inner surface of the movable knife 120, the other end is fixed by a screw 70 in the installation hole 27 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com