Mechanically shaped dry hard concrete ribbed bottom plate and manufacturing method thereof

A technology of dry hard concrete and production methods, which is applied in the field of building floors, can solve the problems of product accuracy, quality assurance, low production efficiency, and long maintenance period, and achieve the effects of labor cost saving, self-weight reduction, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings.

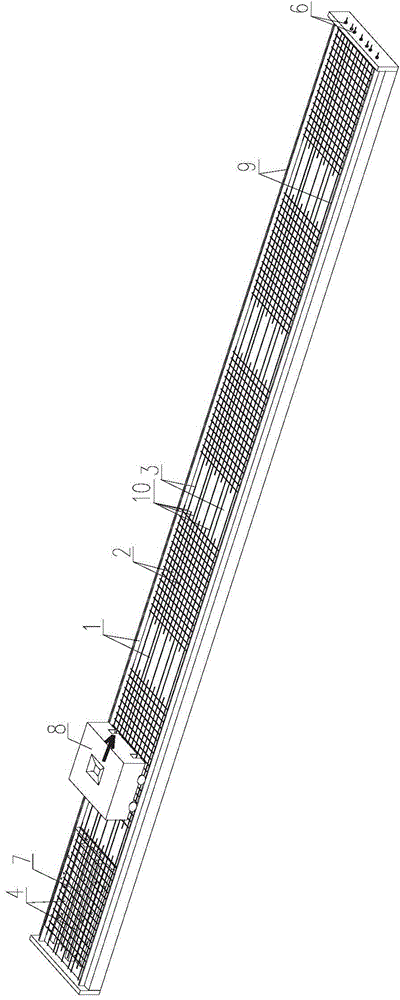

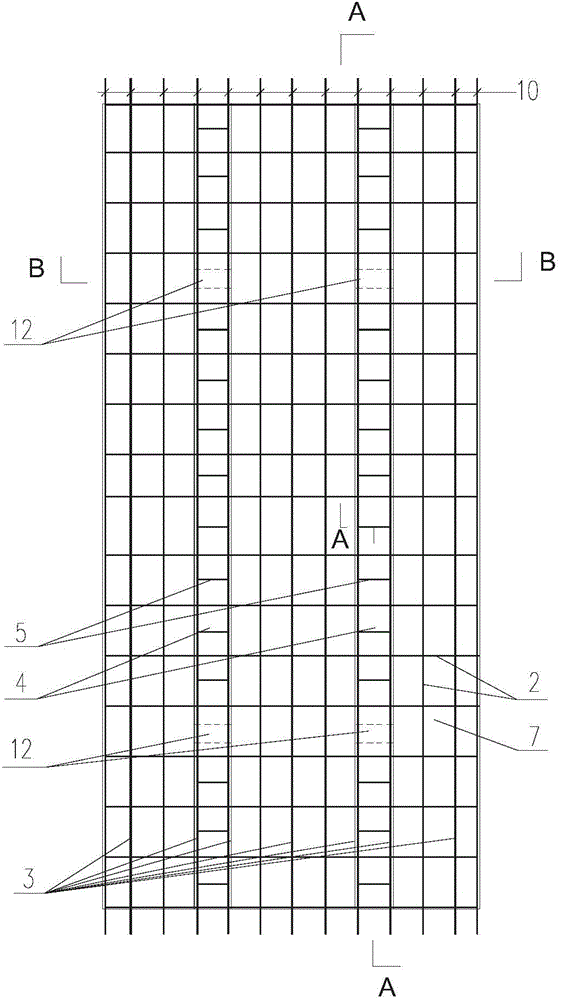

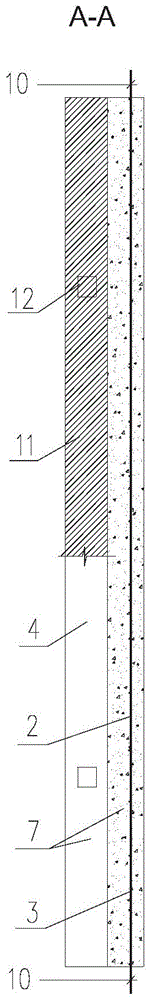

[0046] Such as figure 1 Shown, the manufacture method of a kind of mechanical forming dry hard concrete ribbed floor of the present invention comprises:

[0047] In the extrusion molding die 1 of the production line, the reinforcement mesh 2 and the prestressed reinforcement 3 are laid, and the plate rib support reinforcement 5 is erected at the same time;

[0048] Fix the two ends of the prestressed steel bar 3 by the prestressed tendon anchor 6, tension the prestressed steel bar 3;

[0049] Blanking the dry hard concrete into the extrusion molding die 1 for extrusion molding;

[0050] Cover the curing film on the formed dry hard concrete ribbed floor for curing;

[0051] After the formed dry hard concrete ribbed floor reaches the strength, cut off the prestressed reinforcement 3 and keep the beard reinforcement 10;

[0052] Lift the boards and stack the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap